From cabinet parts to cabinet doors, this edgebander can do it all.

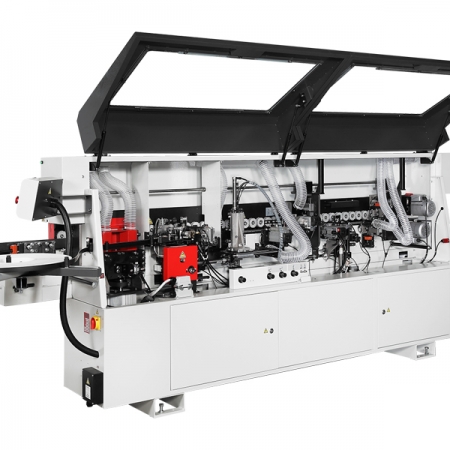

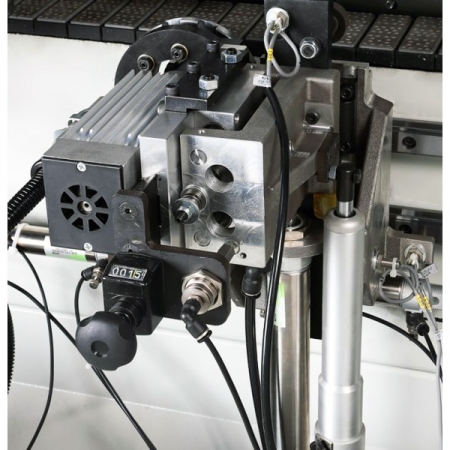

The Cantek MX370P Automatic Edgebander with Premilling and Corner Rounding is designed to be a compact and durable edgebander offered at an affordable price. This machine is equipped with premilling, end trimming, flush trimming, corner rounding, PVC scraping, and buffing. User-friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm.

Why Cantek MX370P Edgebander?

- Versatile edgebander capable of applying 0.4mm to 3mm edge tape.

- Quick change glue pot allows you to change glue colours in minutes.

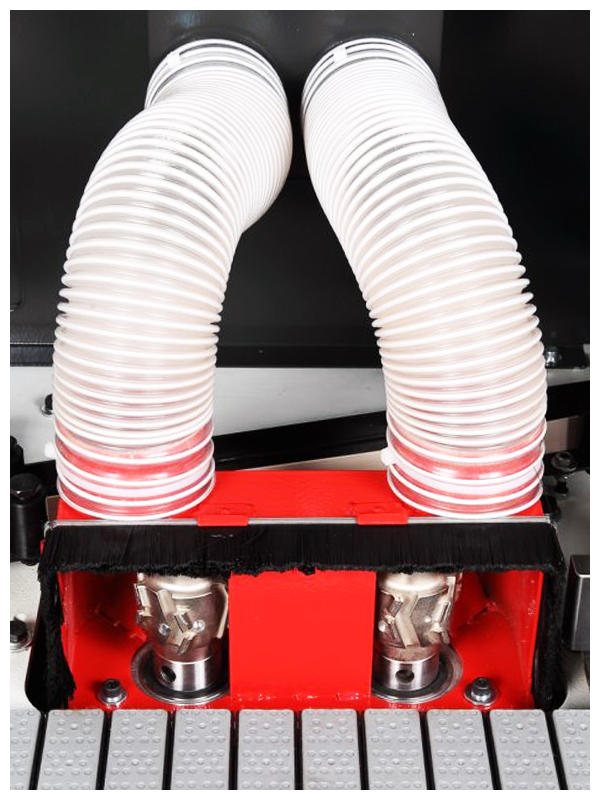

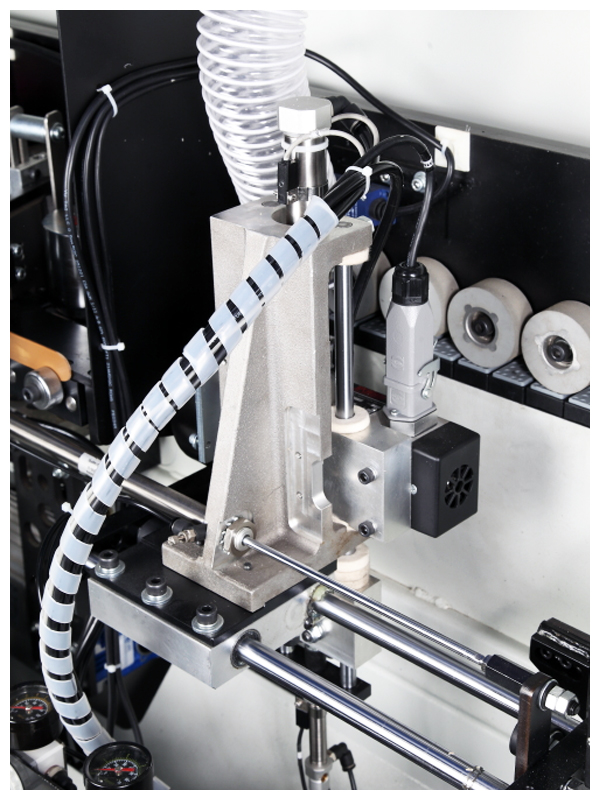

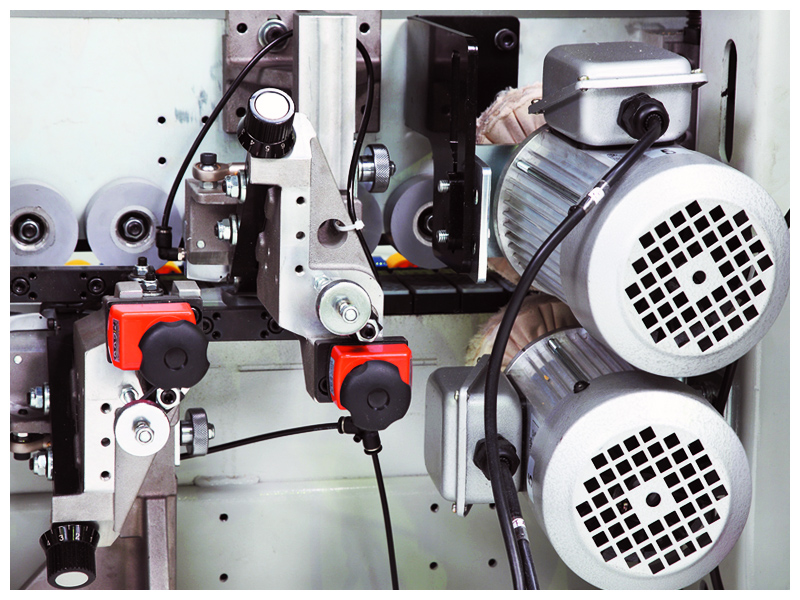

- Premilling ensures a perfectly square edge and clean panel to work with, resulting in a minimally visible glue joint.

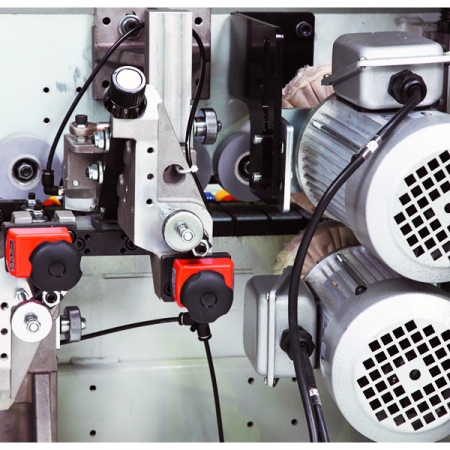

- The corner rounding function finishes the ends of cabinet doors and more with a radius edge, eliminating any manual rework of the panel.

KEY ADVANTAGES

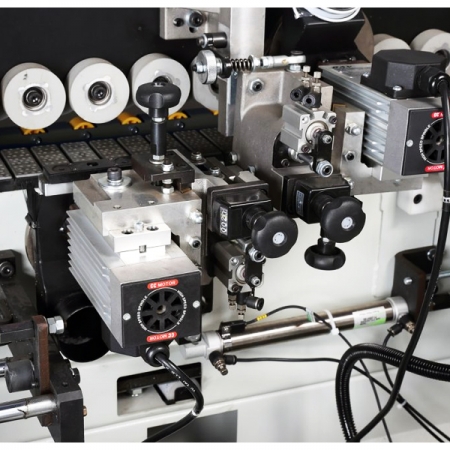

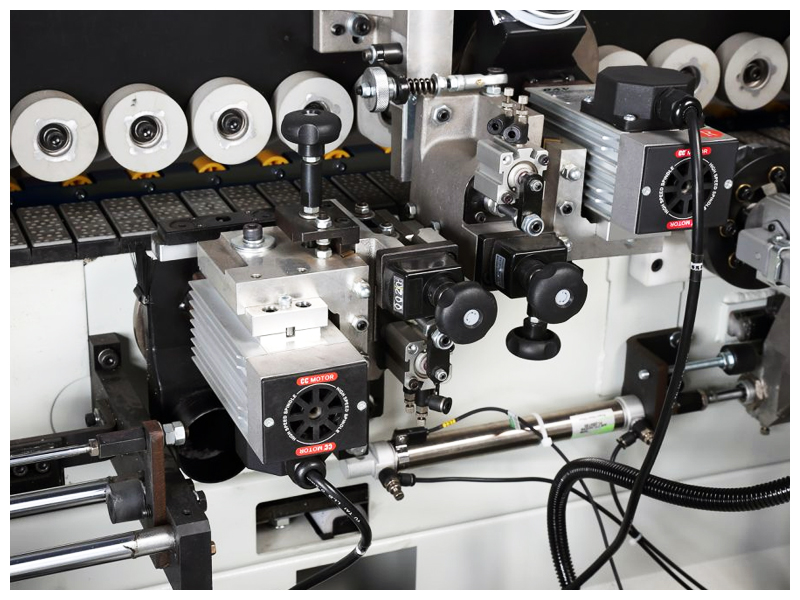

- Automatic edge feeding with a thickness capacity of 0.4–3 mm; strip material can be hand-fed.

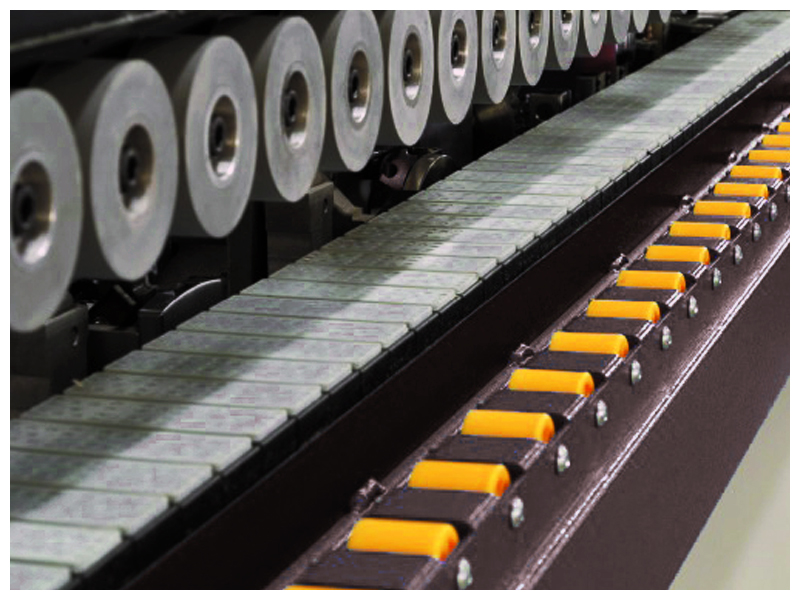

- Conveyor chain feed system for reliable results.

- Teflon-coated hot-melt glue pot.

- Heated infeed fence for pre-heating the panel for optimum glue penetration.

- PLC control system with LED display and keypad.

- Workpiece is fed by chain.

- Edge coil support plate: Ø 800mm (31 ½”), for PVC/ABS.

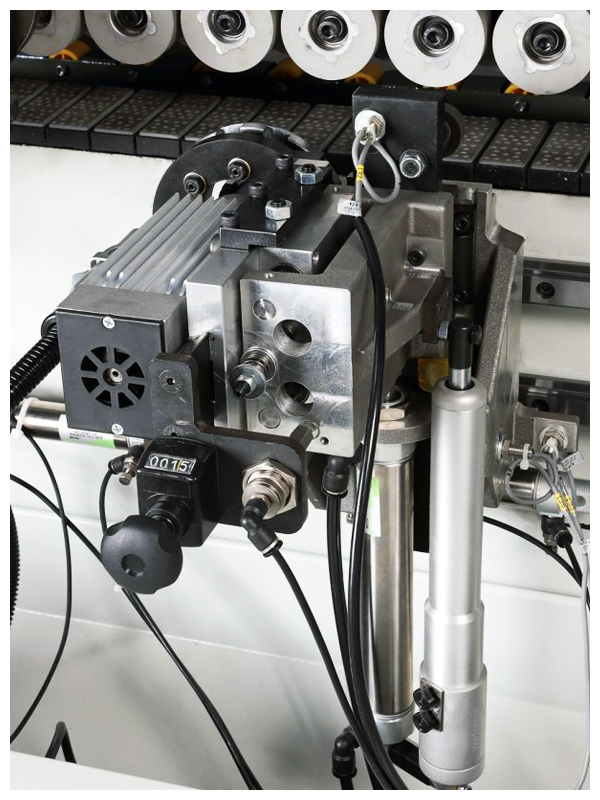

- Spring-loaded pressure unit with (2) pressure rollers.

- Heavy-duty pressure beam with extendable workpiece support.

WORKING UNITS

SPECIFICATIONS

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.

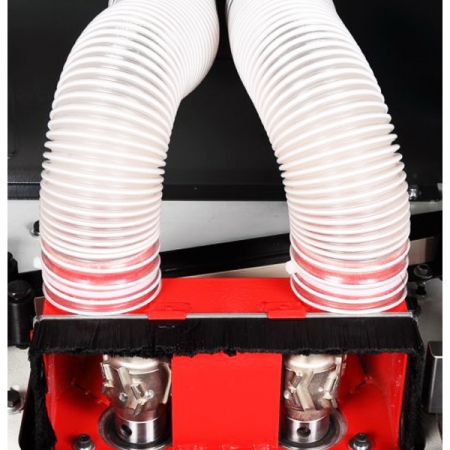

Pre-milling for Edgebanders.

Machinery SolutionsMore often today you are finding features on smaller edge banders that initially were exclusive to larger, higher production machines. One of those features is pre-milling. Pre-milling consists of two counter-rotating cutterheads which are designed to mill the edge of the panel prior to applying the edge banding material.