Compact edgebander with pre-milling for best-in-class results.

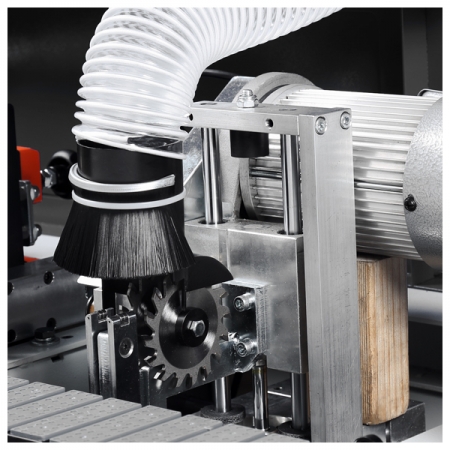

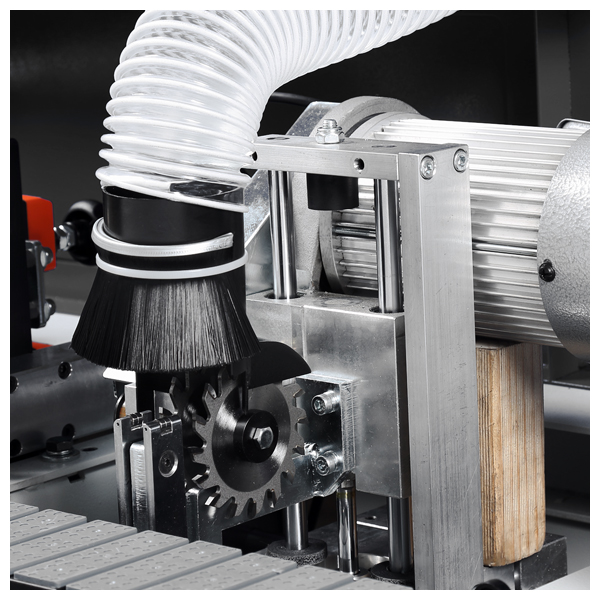

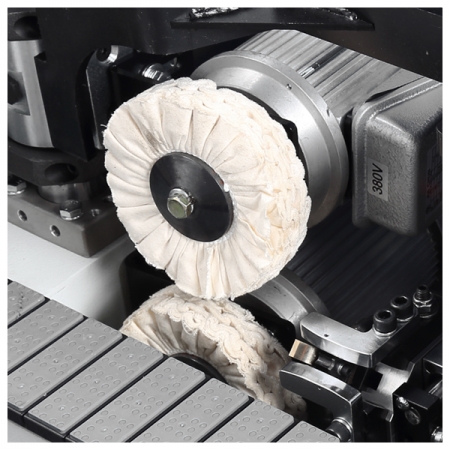

The Cantek MX350M Automatic Edgebander is an entry level edgebander with pre-milling that is the perfect blend of quality and affordability. With fine attention to detail and quality componentry, the MX350M can output high quality edges on cabinet parts and more. The pre-milling diamond cutterheads machine the panel just prior to applying the glue to ensure optimum edge quality prior to applying the edge tape. Additionally, the machine is equipped with end trimming, flush trimming, PVC scraping, and buffing. User friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm.

Why Cantek MX350M Automatic Edgebander?

- Compact design makes it the ideal edgebanding solution for small workshops

- Pre-milling the panel ensures optimum edge quality prior to edgebanding

- Precise adjustments for optimum edge quality

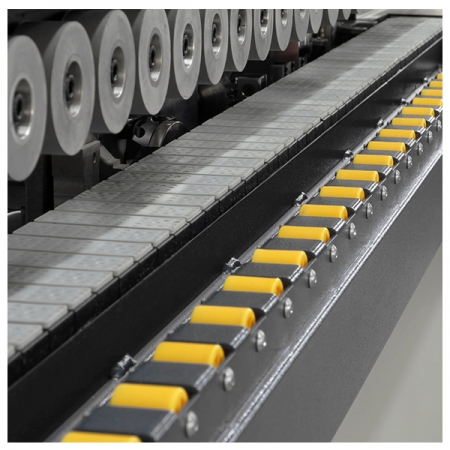

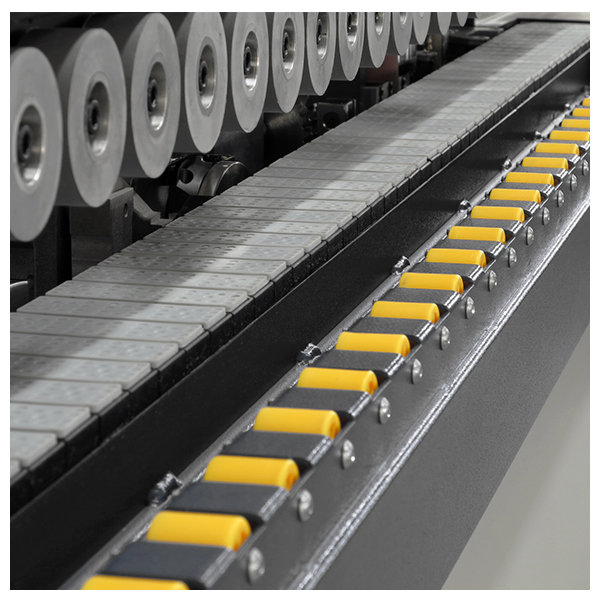

- Chain feed system ensures consistent feeding of material for consistent results

- Available in 230V 1 or 3 phase

- PLC control system with LED display and keypad

- Workpiece is fed by chain

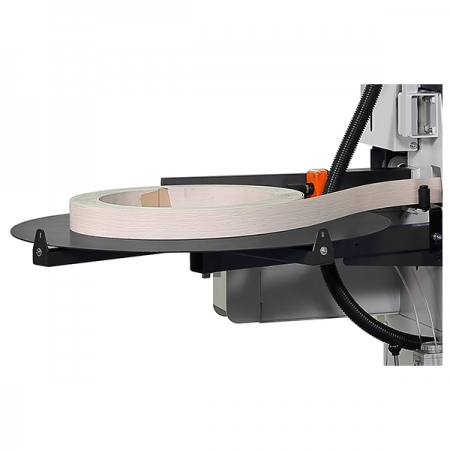

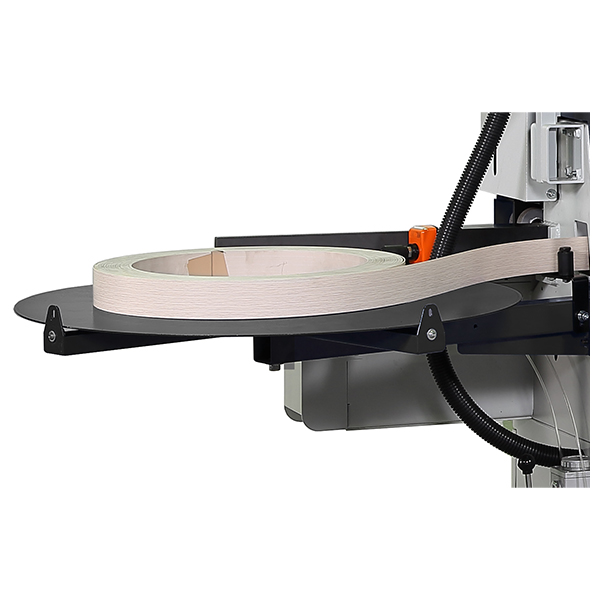

- Edge coil support plate: Ø 800 mm (31.5″), for PVC/ABS

- Automatic edge feeding with a thickness capacity of 0.4-3 mm;

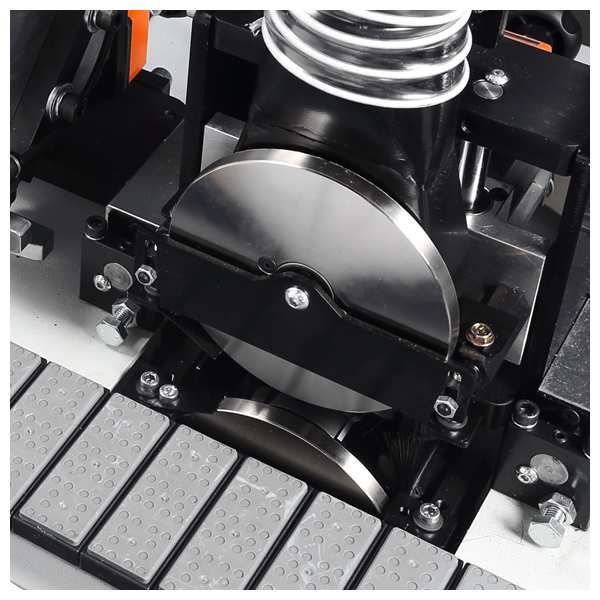

- Coiled edge bands up to 3 mm in thickness in Hard-PVC/ABS are cut with guillotine shears.

- 2 kg (2.64 lb) Teflon-coated hot-melt glue pot

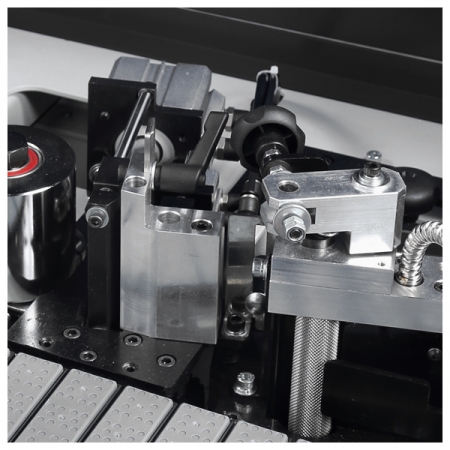

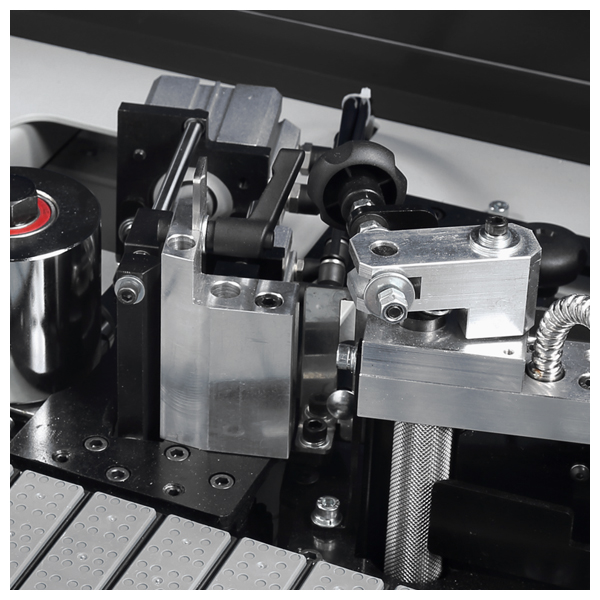

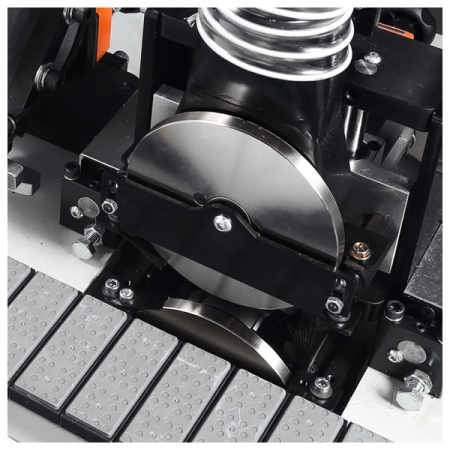

- Spring loaded pressure unit with (2) pressure rollers (1 chrome & 1 rubber)

- Heavy duty pressure beam with extendable work-piece support

- Heated infeed fence for pre-heating the panel for optimum glue penetration

- Mechanical digital readouts for convenient and quick adjustment to the working units & thickness

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.