Wide double-sided planer with big capacity.

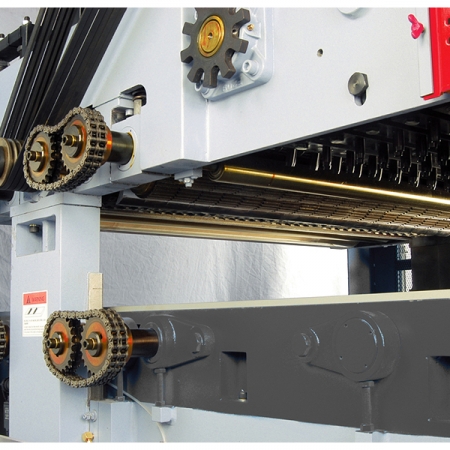

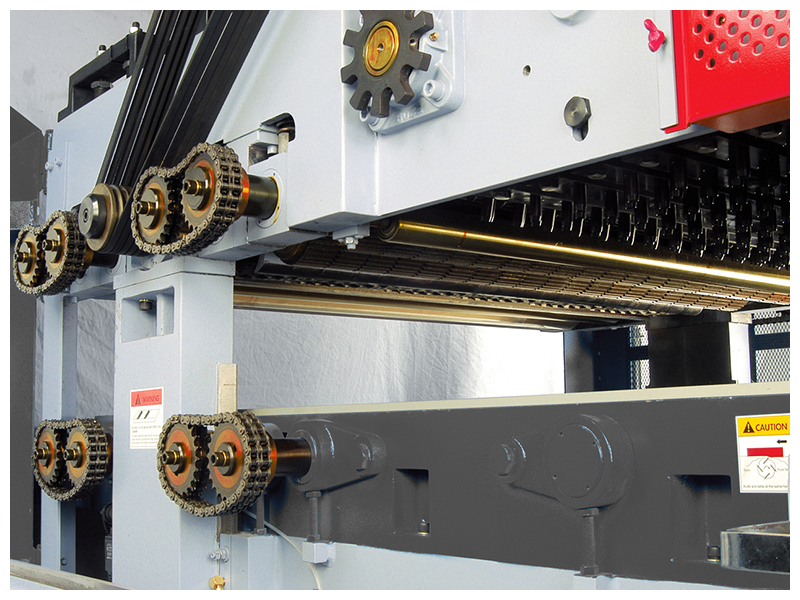

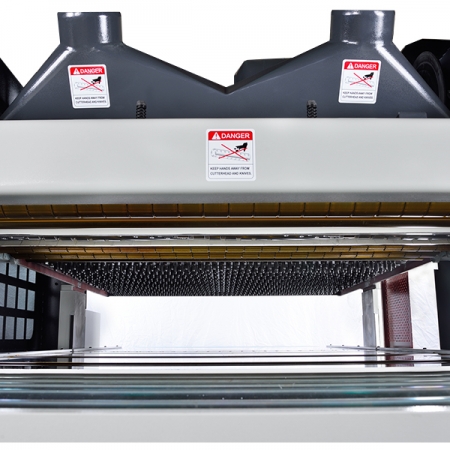

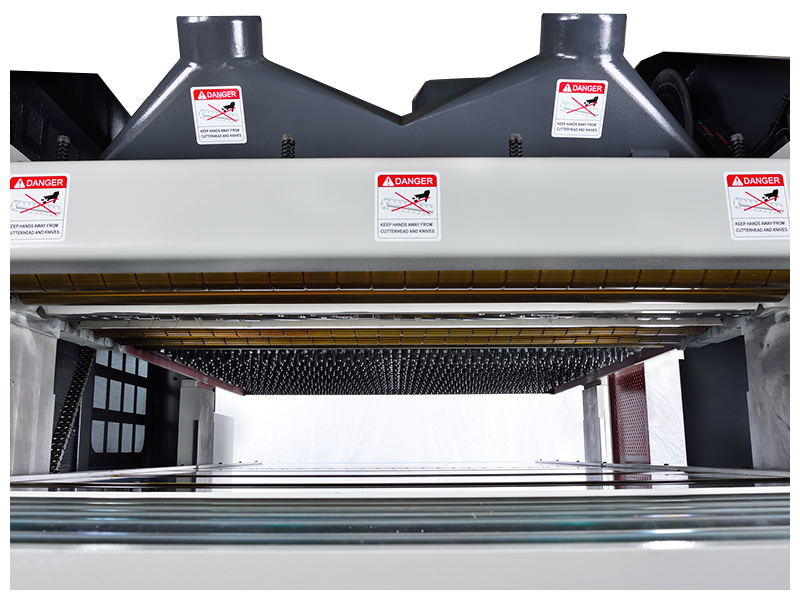

The Cantek GTM1020W 40” Double Surface Planer has a robust cast-iron body for industrial planing day in and day out. The spiral insert knife cutterheads produce a smooth planed finish with maximum stock removal. The material is passed over the bottom head with a spring-loaded pin feed system while the infeed bed is adjustable to determine how much material is removed. The final thickness is keyed in the digital control and the top head & feed assembly automatically move in place. This wide planer is ideal for increasing production on narrow boards and capable of planning live edge slabs, countertops, table tops, door panels, and more.

Why Cantek GTM1020W 40″ Double Surface Planer?

- Big capacity of up to 40″ wide x 11.8″ thickness

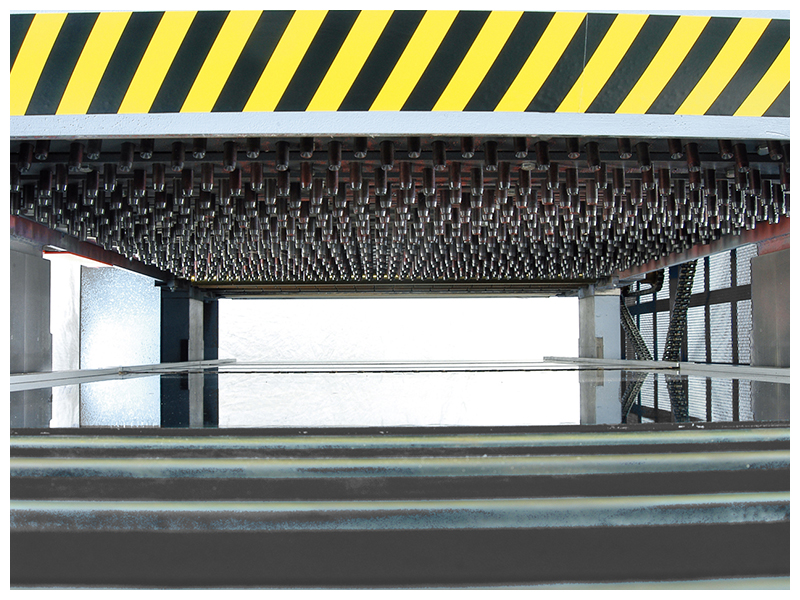

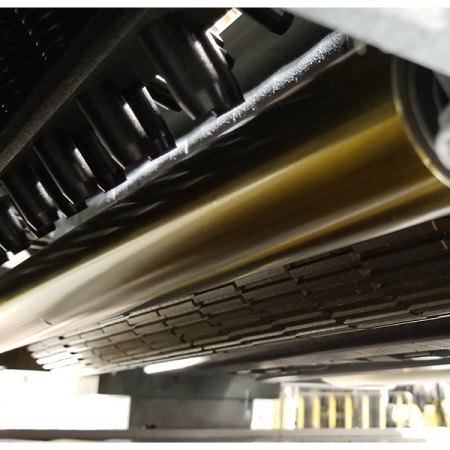

- Spring loaded conveyor pin system ensures material is passed over the bottom cutterhead to resulting in a flat and uniform board prior to planing to thickness on the top head

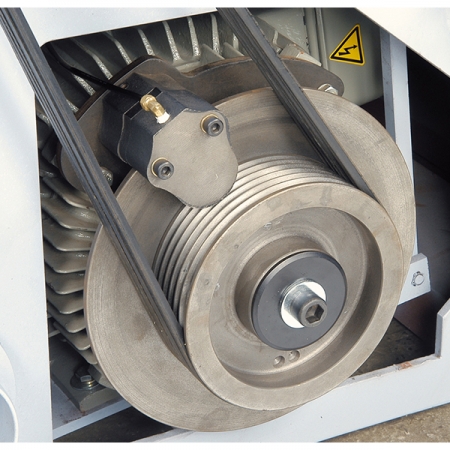

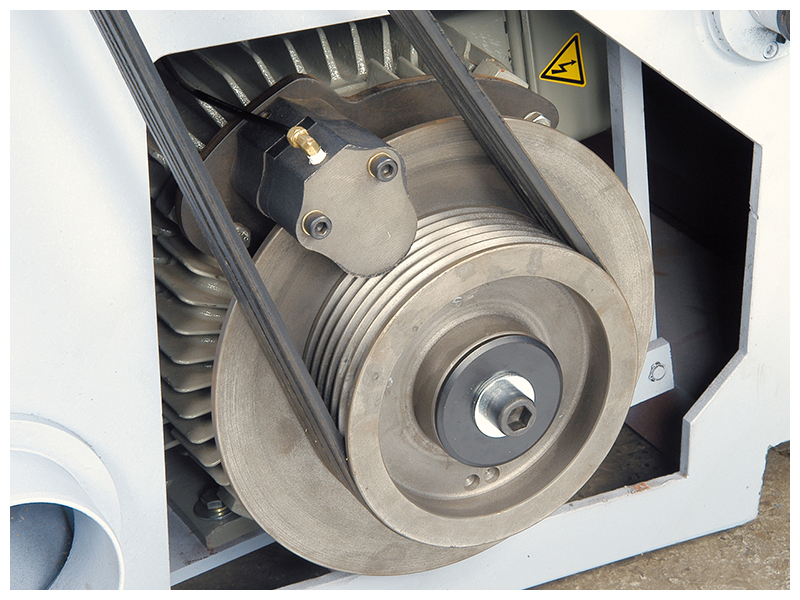

- Spiral insert knife cutterheads with two-sided solid carbide knives produce a smooth finish with increased stock removal capacity and extremely quiet operation

- Heavy-duty cast-iron machine body and table for vibration free cutting

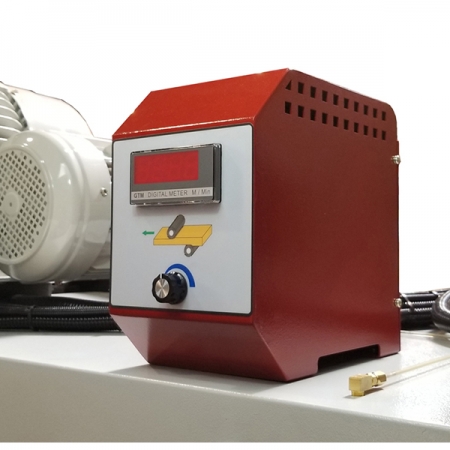

- Digital electronic thickness adjustment in INCH and MM (Inch = 0.001” / mm = 0.01mm resolution) for precise thickness control

- Cutterheads are spiral insert type with six (6) rows of carbide inserts

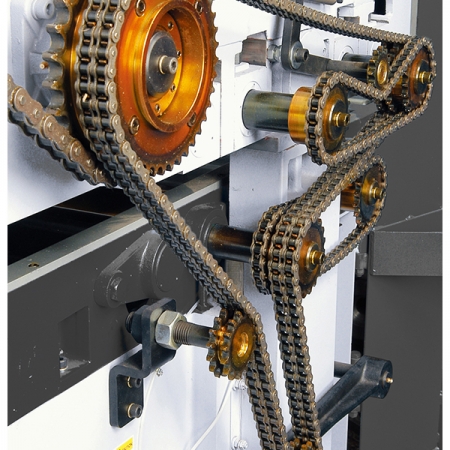

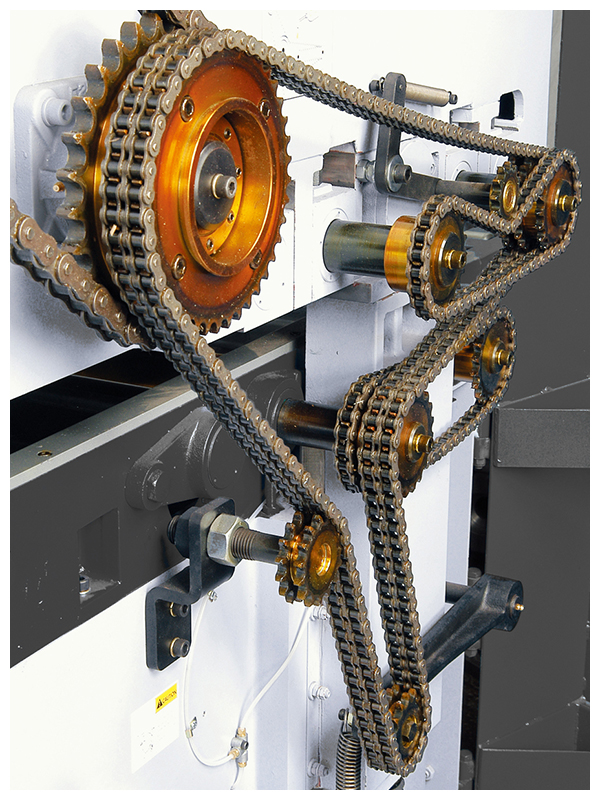

- (2) driven and (1) idle bed roll for superior feeding of even difficult material

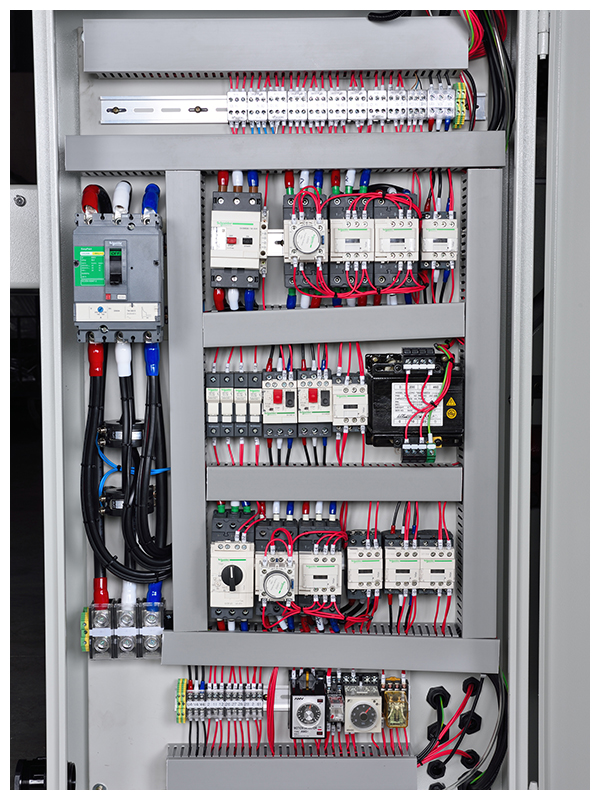

- Swiveling control panel for more ergonomic access to machine controls

- Inverter variable speed control with feed speeds from 26 to 80 FPM

- Easy to access external handwheel adjustment of infeed bed

- Hard chromed worktable for high wear resistance

- Auto lubrication to conveyor chain, central lubrication for dovetail elevation guideways

- Section chip breaker and sectional feed roller before top cutterhead

- Rubber outfeed top roller to prevent chip marking

- Over thickness safety shut-off bar across infeed.

- Ammeter for each motor on control panel to monitor motor load

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.