Plane your material efficiently in a single pass.

The Cantek GT635ARD 25″ double surface planer has a robust cast-iron body for industrial planing day in and day out. The spiral insert knife cutterheads produce a smooth planed finish with maximum stock removal. The material is passed over the bottom head with a spring-loaded pin feed system while the infeed bed is adjustable to determine how much material is removed. The final thickness is keyed in the digital control and the top head & feed assembly automatically move in place.

Why Cantek GT635ARD 25″ Double Surface Planer?

- Spring loaded conveyor pin system ensures material is passed over the bottom cutterhead to resulting in a flat and uniform board prior to planing to thickness on the top head

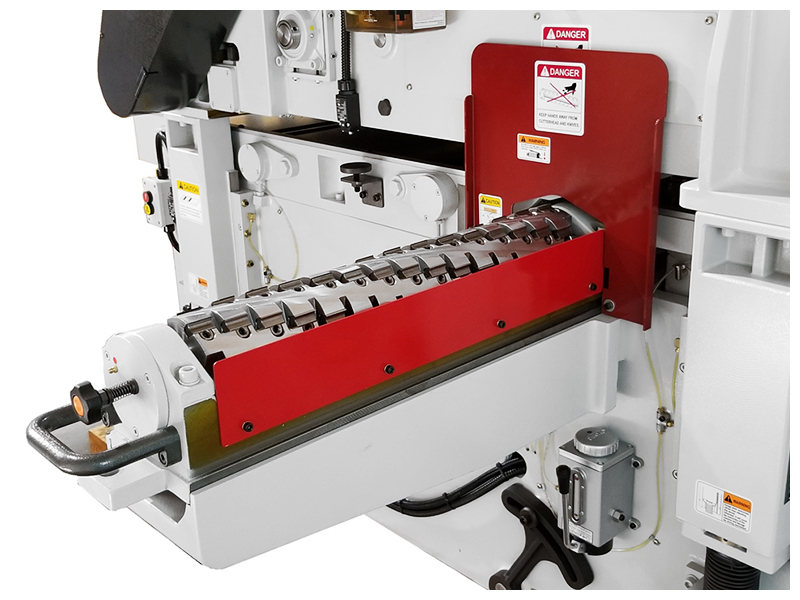

- Spiral insert knife cutterheads with two-sided solid carbide knives produce a smooth finish with increased stock removal capacity and extremely quiet operation

- Heavy-duty cast-iron machine body and table for vibration free cutting

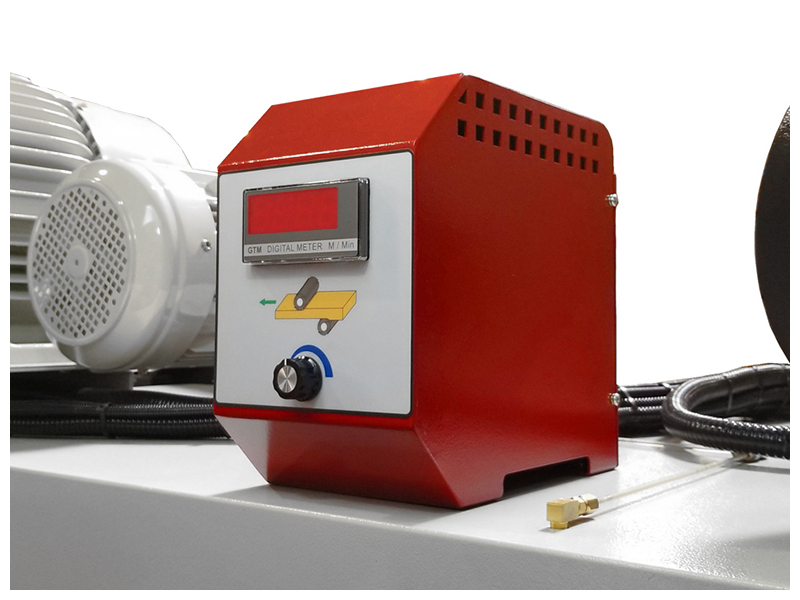

- Digital electronic thickness adjustment in INCH and MM (Inch = 0.001” / mm = 0.01mm resolution) for precise thickness control

KEY ADVANTAGES

- 25″ x 8″ capacity as standard with optional 16″, 20″, 24″ thickness capacity

- Cutterheads are spiral insert type with six (6) rows of carbide inserts

- (2) driven and (1) idle bed roll for superior feeding of even difficult material

- Swiveling control panel for more ergonomic access to machine controls

- Inverter variable speed control with feed speeds from 26 to 80 FPM

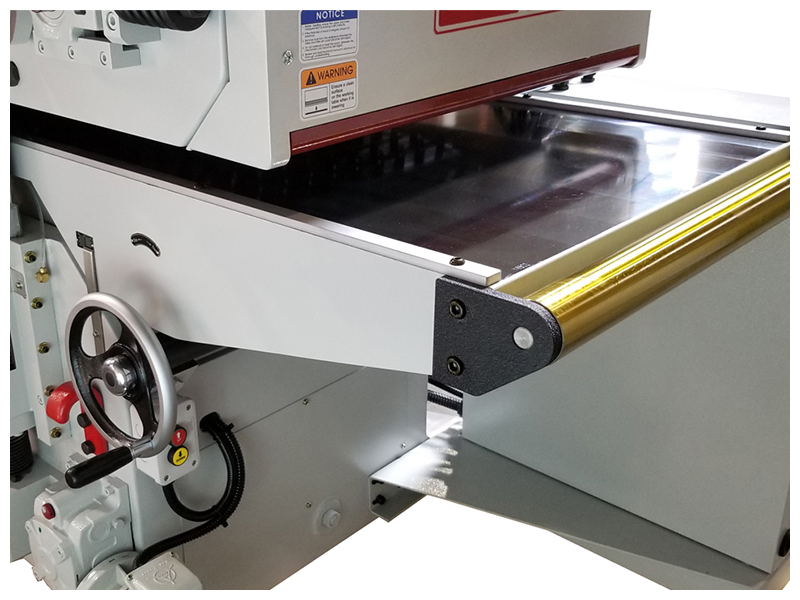

- Easy to access external handwheel adjustment of infeed bed

- Hard chromed worktable for high wear resistance

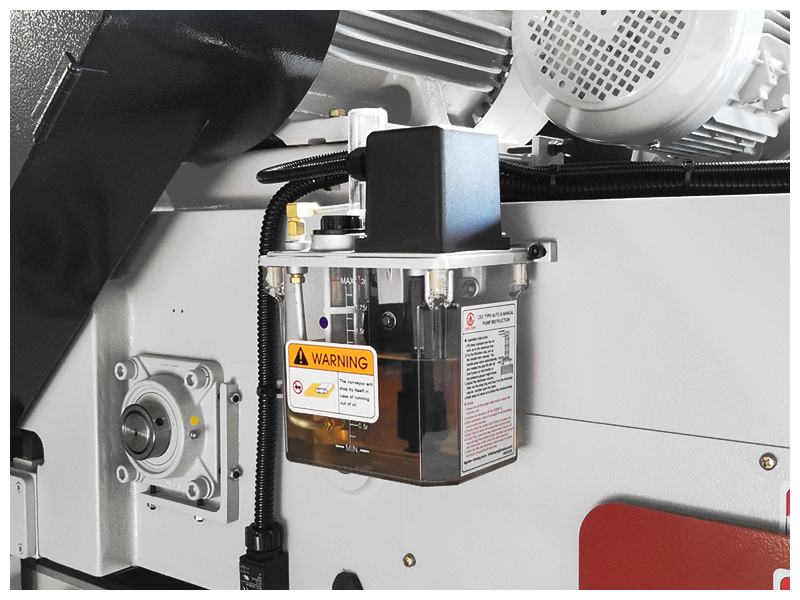

- Auto lubrication to conveyor chain, central lubrication for dovetail elevation guideways

- Section chipbreaker and sectional feed roller before top cutterhead

- Rubber outfeed top roller to prevent chip marking

- Over thickness safety shut-off bar across infeed.

- Ammeter for each motor on control panel to monitor motor load

SPECIFICATIONS

SERVICE

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.