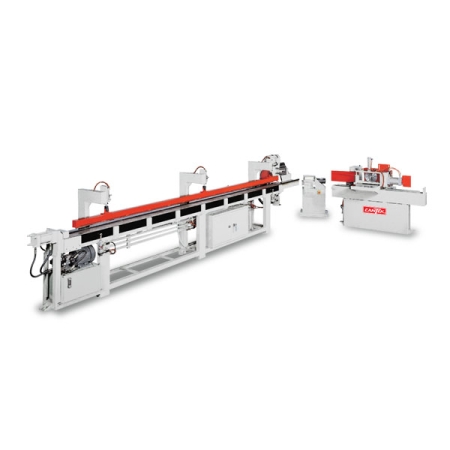

The entry-level semi-automatic finger jointer that is perfect for shops with low-production requirements.

The Cantek FJ17 Semi-Automatic Finger Jointer is simple in design and easy to operate, it offers exceptional affordability and is perfectly suited for workshops where production volumes don’t warrant investment in a higher production system. Its pioneering technology is thoughtfully engineered and seamlessly incorporates user-friendly attributes, by utilizing an automatic shaper to conveyor setup, this system delivers extraordinary value in performance and affordability. Despite its simple design, this finger jointing system doesn’t compromise on quality or performance, establishing itself as a lasting and groundbreaking manual solution in the woodworking industry.

Why Cantek FJ17 Semi-Automatic Finger Jointer?

- Entry-level model

- Cost-effective model

- Easy to operate

- Low maintenance

- 4 operators are required for maximum production

- The F-C55 semi-automatic finger shaper consists of a trim saw, a shaper, and a moving table to cut the left side of the workpiece.

- The F-C56 semi-automatic finger shaper consists of a trim saw, a shaper, a glue applicator, and a moving table to cut the right side of the workpiece.

- The F-D05 transfer roller tables (3 per set) allow the workpieces to travel between the workstations, reducing downtime to a minimum, and allows the operator to inspect material quality without delay.

- The F-A05 assembly press is suited for jointing two workpieces up to 14 ½ feet or 20 feet in length. Using a two-step sequence of finger assembler from feeding, and multiple-step cut-off pressing, the outfeed is synchronized.