Designed for Small and Medium Shops looking for High Efficiency and Throughput

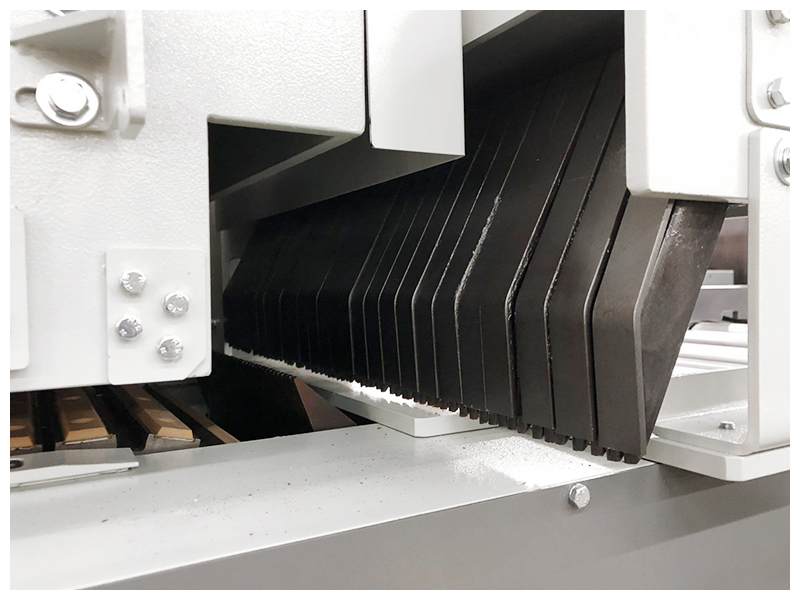

The Skew Rip System from Cameron Automation is a highly efficient, inexpensive, full featured, rip optimization system designed to fit any 12″ wide gang rip saw and specifically developed for the custom shop. The unique feature of The Skew is the “skewing fence”. It has the ability to twist and feed the board into the saw to get the best yield. The Skew also has all the features of the high-end optimization systems like: lumber tallying, pack reporting, bundle reporting, yield calculations, simulations, and much more. The greatest benefit of The Skew is the Return on Investment, which can be well under 1 year. Cameron Automation has pushed the envelope once again to simplify sophisticated equipment and bring it to the small shop to increase yield and save labor. The Skew Rip System is the answer for Rip Optimization in a custom shop. It will quickly transform any small hand-fed gang saw into a full and complete rip optimization system. Cameron has further refined their rip software to make it easy and affordable for the small shop while still offering the same features as their bigger systems.

Why Cameron Automation Skew Rip System?

- Increased operator safety

- 7 – 10% increase in yield

- Extremely accurate positioning of boards (no yield loss due to misalignment)

- Arbor optimization

- Simulate production runs using actual board data

- Tallies both incoming and outgoing material automatically

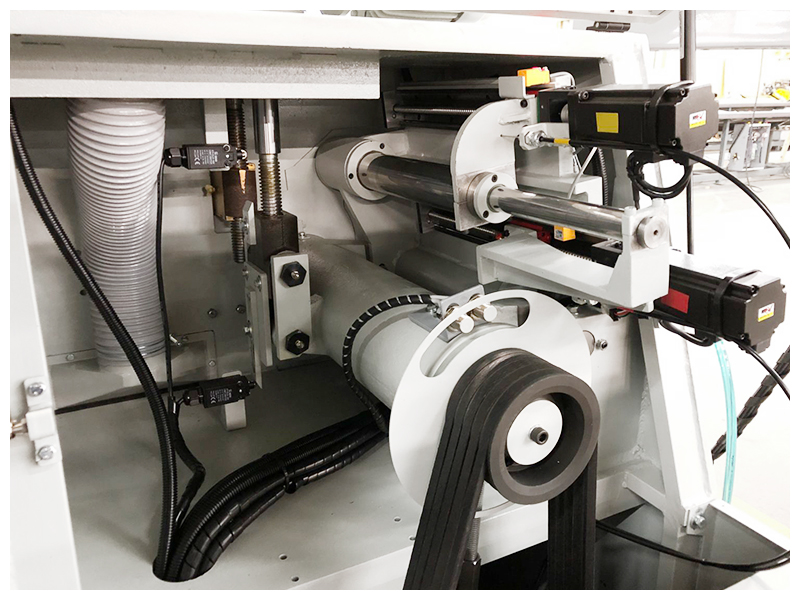

- Communicates with moving blade saws to position blades automatically

- Single operator loads and defects

- Full Optimizing Infeed

- 12″ Wide Arbor, (2) Moving and Multiple Fixed Blade Rip Saw

- Auto-Skew to Increase Board Yield

- Fully Integrated Software Package

- Automatic Movable Blade Positioning by the Cameron Software

- Industry leading features with the Auto-Skew and Over/Under design.

- Powerful Software to help improve your business and make you more profitable.

- Significant yield increases that go directly to the bottom line by decreasing lumber bills and improving productivity

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.