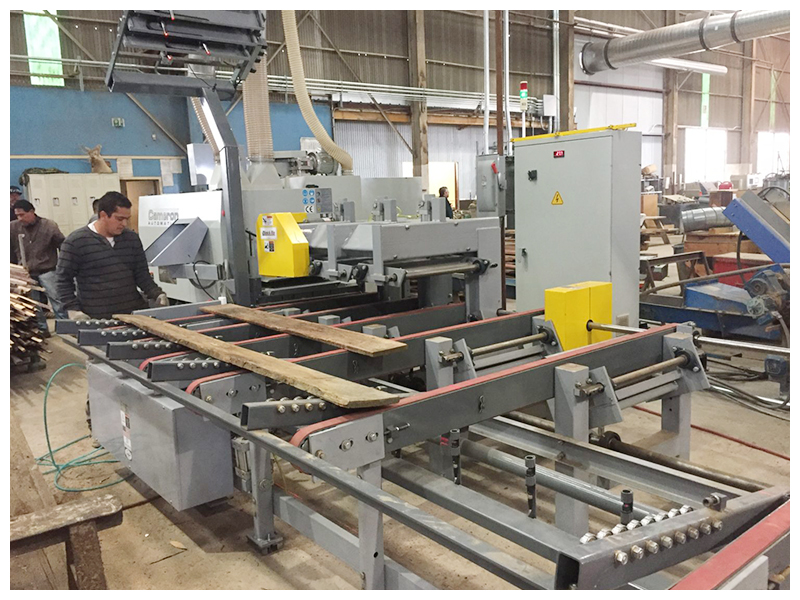

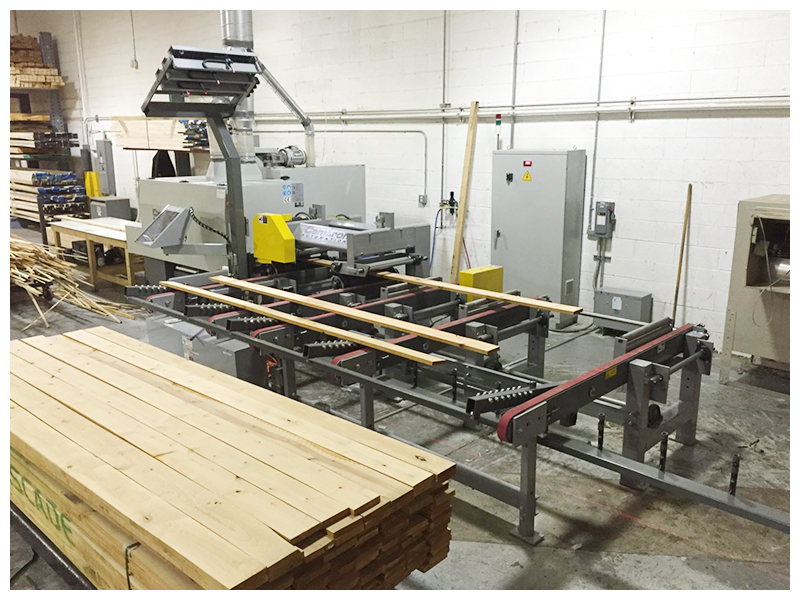

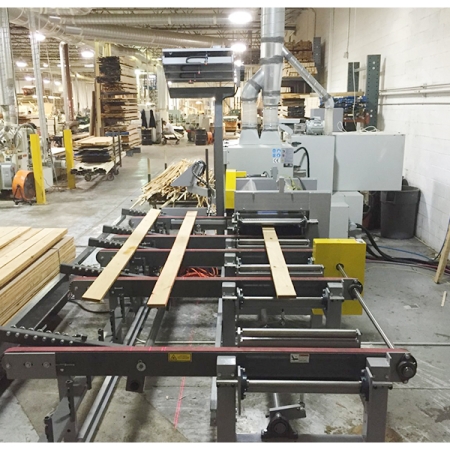

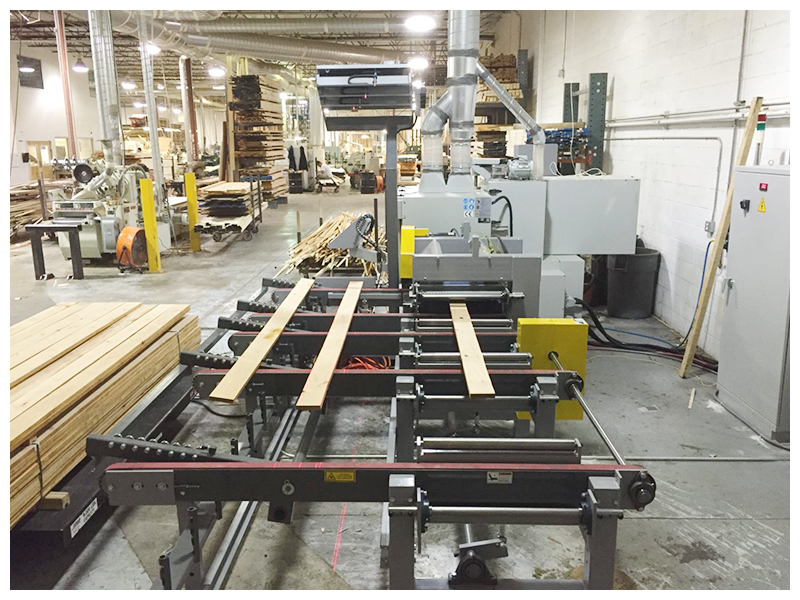

Designed for the Medium and Large Shops looking for maximum yield and throughput.

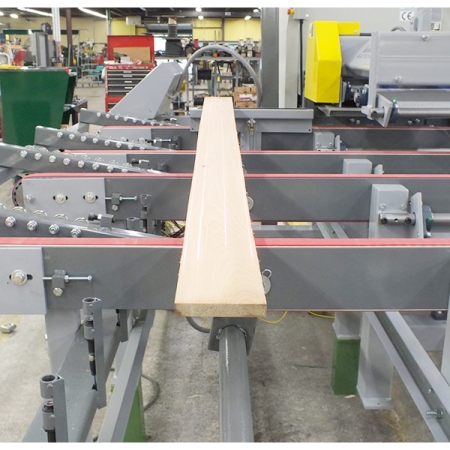

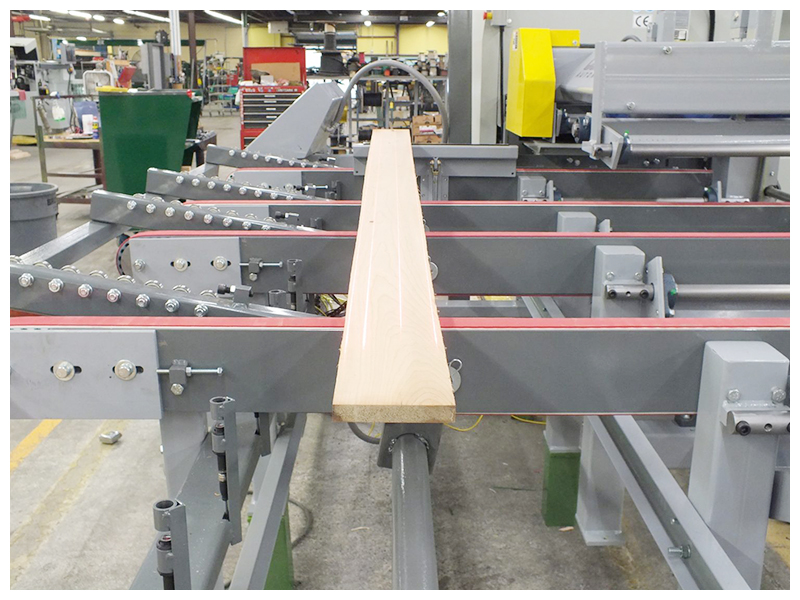

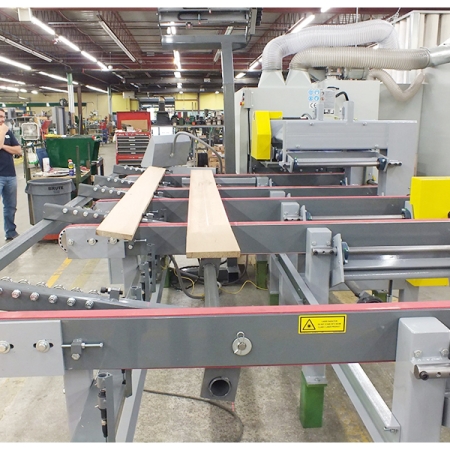

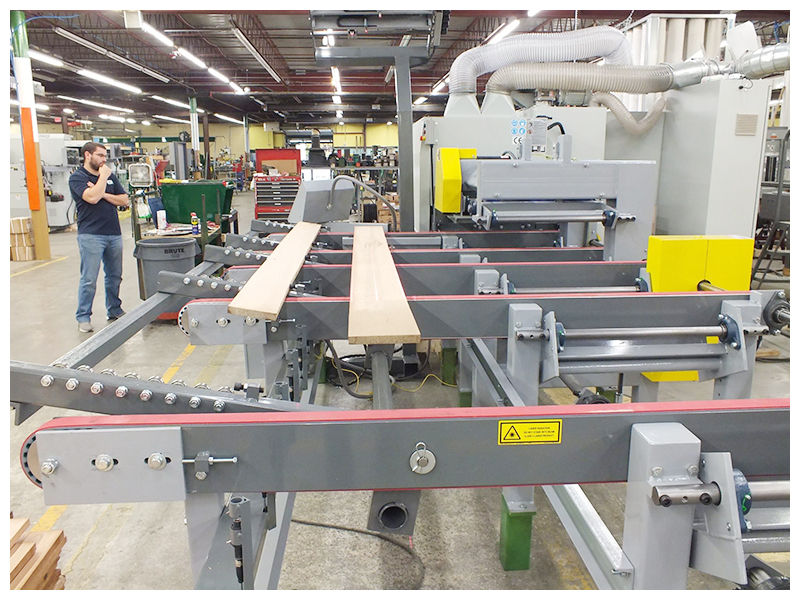

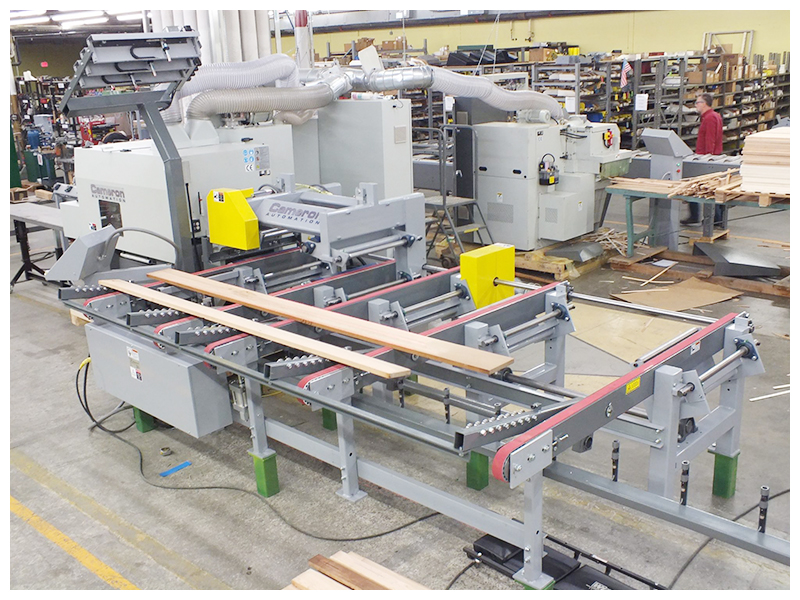

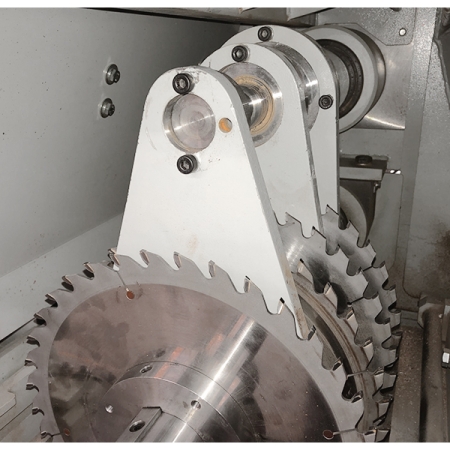

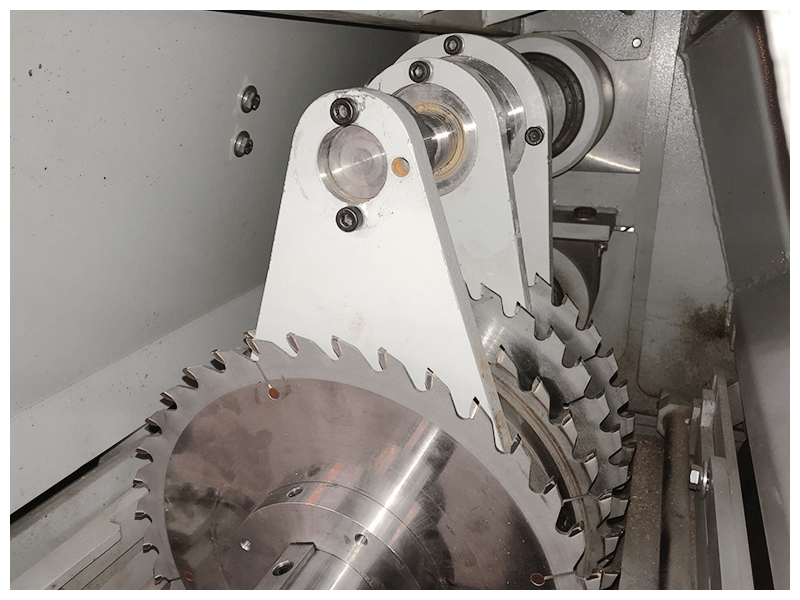

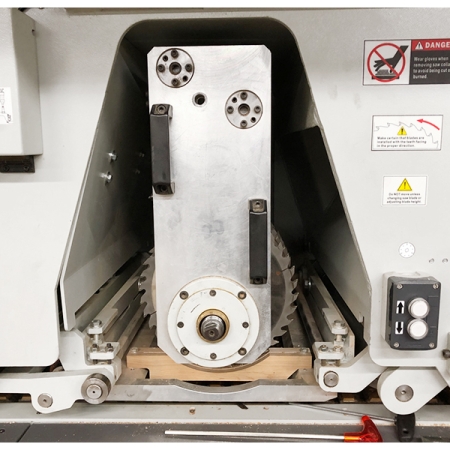

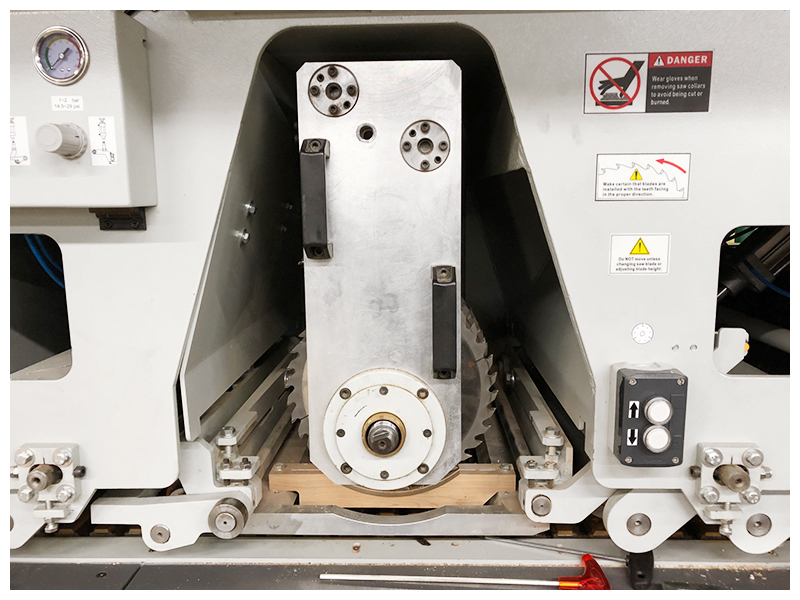

The Quick Rip System from Cameron Automation is a mid-range optimization system for shops ripping 6,000 – 18,000 board feet per shift. It offers the highest yield in the market due to its fenceless design, powerful “Opti-Rip” optimizing software, and multiple moving blade technology in a few different model saws. Non straight boards are handled just as effectively as straight boards and the net result is lower raw material costs. Unlike other systems, the Quick Rip is fenceless and has Auto Skewing for achieving highest possible yield. The sensors read the width, the length, and the shape of the boards. If a board has crook or taper, the software can determine if the board should be skewed for higher yield. If so, it happens automatically. This adds up to an additional 3% yield over systems with a fence. Quick Rips can be paired with Moving Blade Saws that come with (2), (3) or (4) moving blades depending on your cut bill and lumber. The Cameron Opti-Rip software is written in-house allowing changes, improvements and free upgrades to happen on a regular basis.

Why Cameron Automation Quick Rip System?

- 7 – 10% increase in yield

- Extremely accurate positioning of boards (no yield loss due to misalignment)

- High throughput (10 – 12 or more boards/minute). 17 for flooring (fixed arbor saw)

- Increased operator safety

- Tallies material automatically

- Catalogue each and every board

- Machine ships assembled and is up and running in 1 day

- Moving laser lights for zero setup

- Cameron Quick Rip Infeed with Fenceless, Servo-Driven Board Positioner with Extremely High Accuracy

- Multiple Moving Blade, Multiple Fixed Blade Setups

- Completely Integrated Software Package

- Automatic Movable Blade Positioning by the Cameron Software

- Highest board yield on the market

- Industry leading features with the Auto-Skew and Over/Under design.

- Powerful Software to help improve your business and make you more profitable.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.