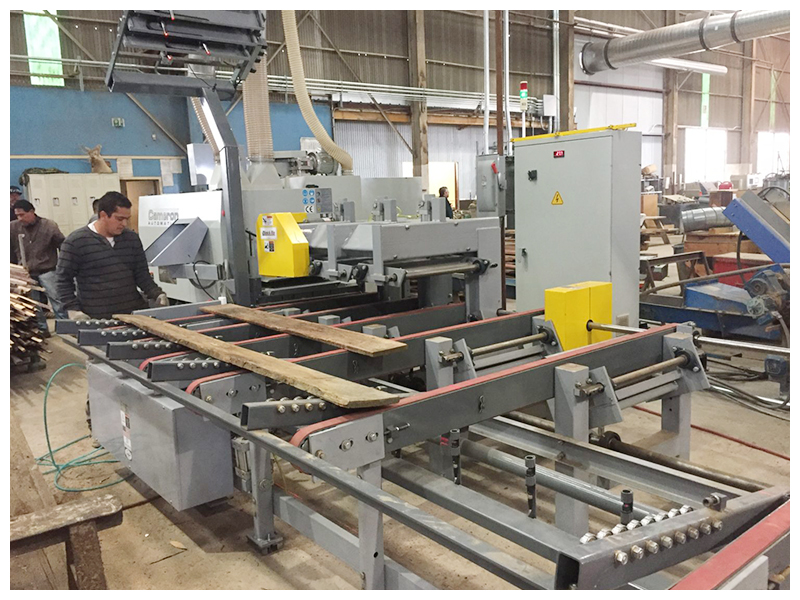

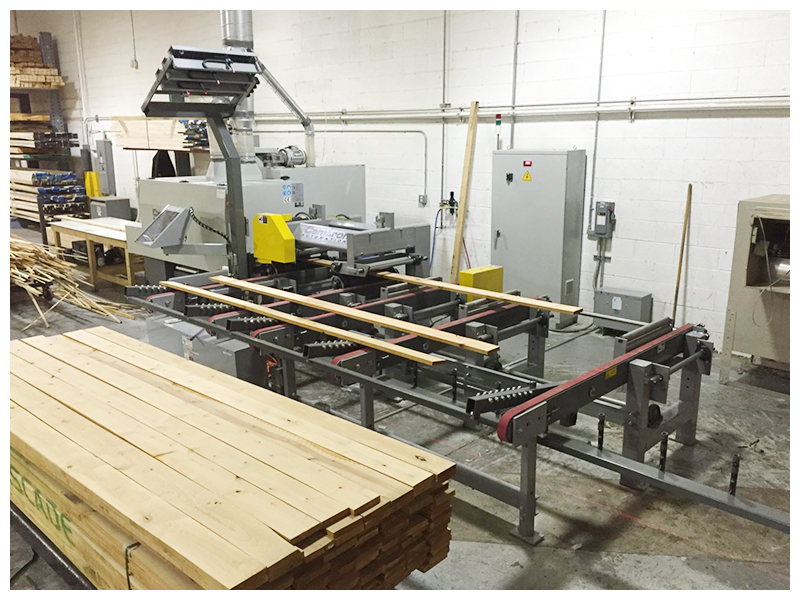

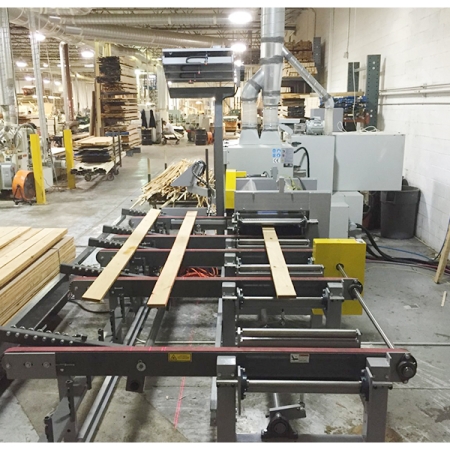

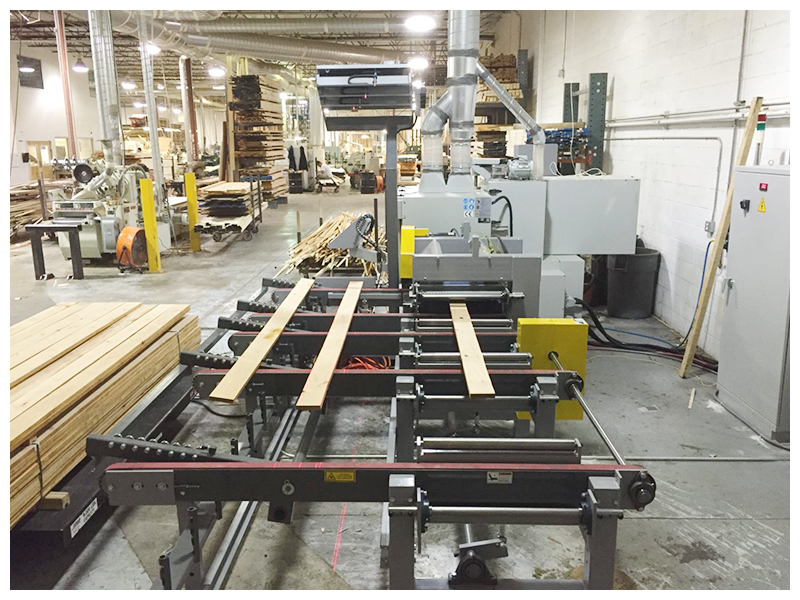

Designed for the Medium and Large Shops looking for maximum yield and throughput.

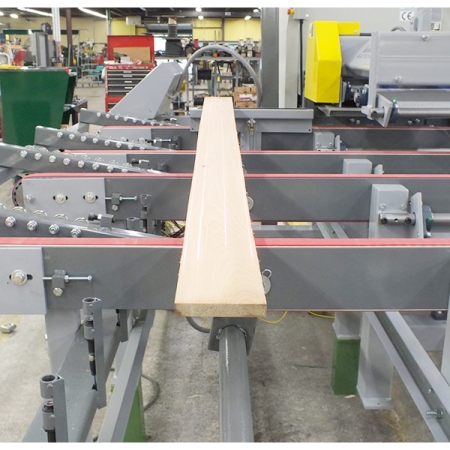

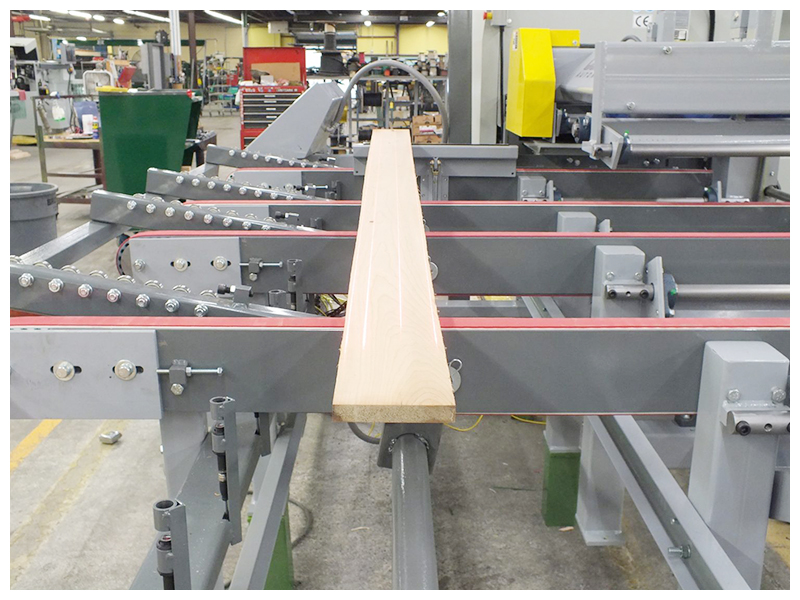

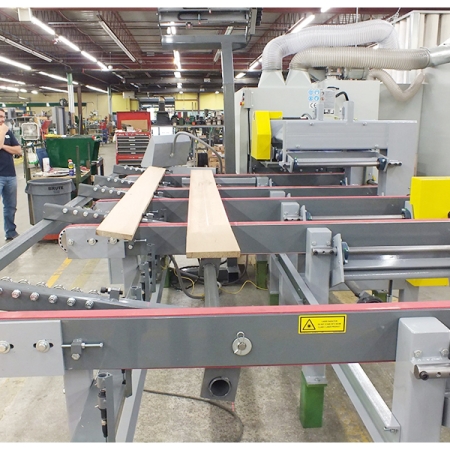

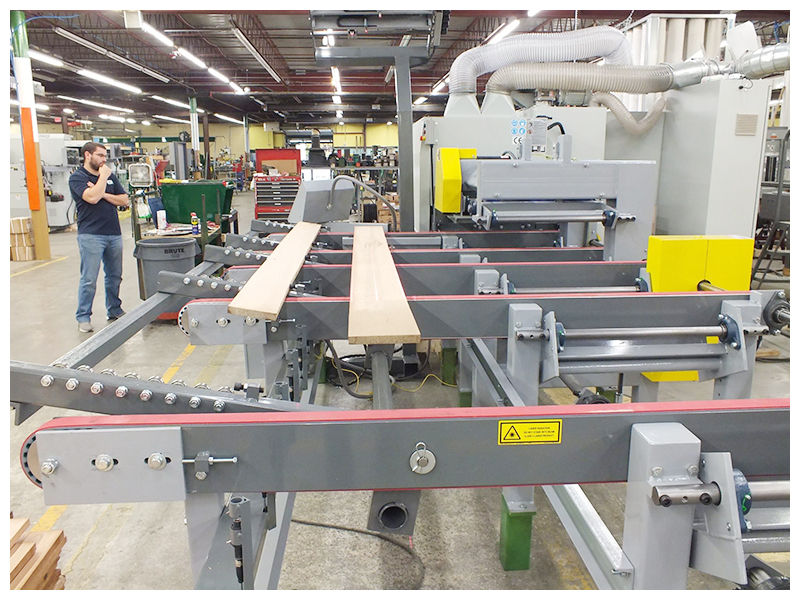

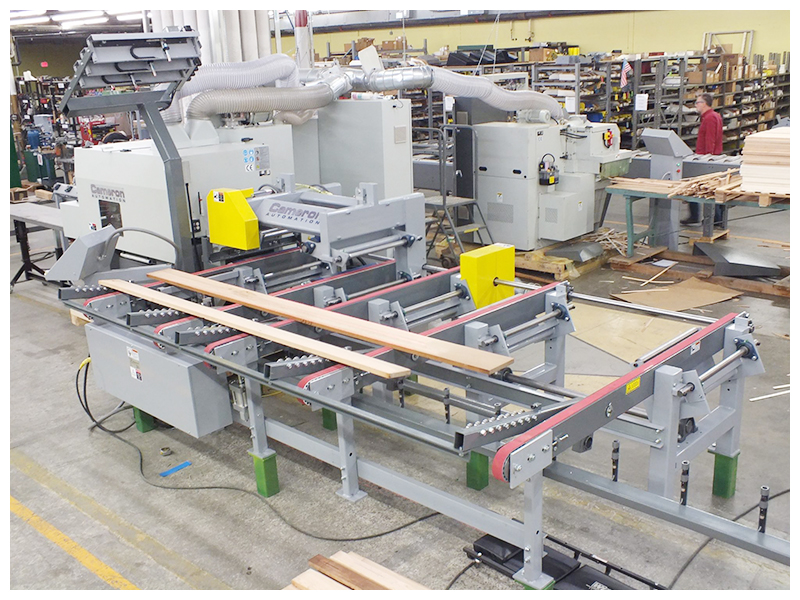

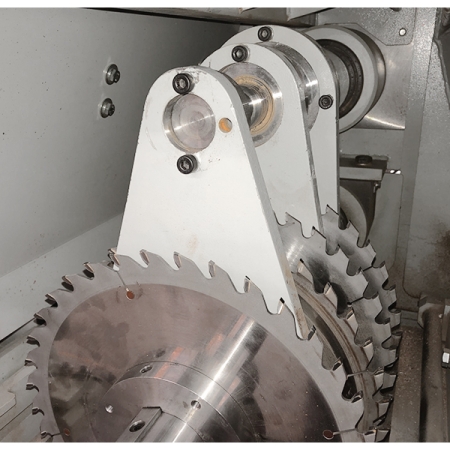

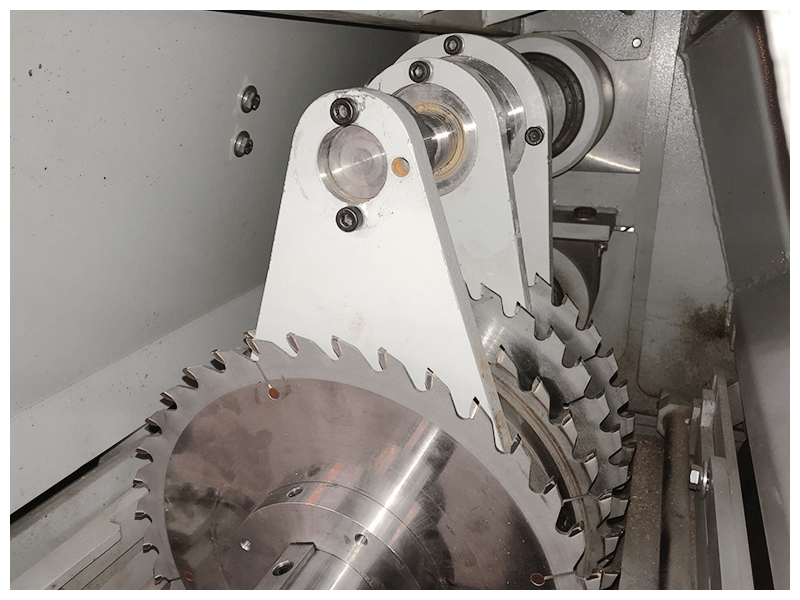

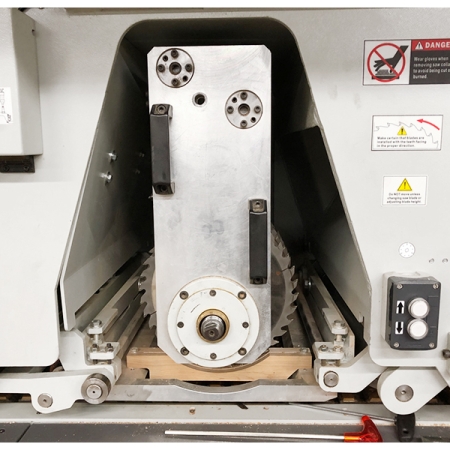

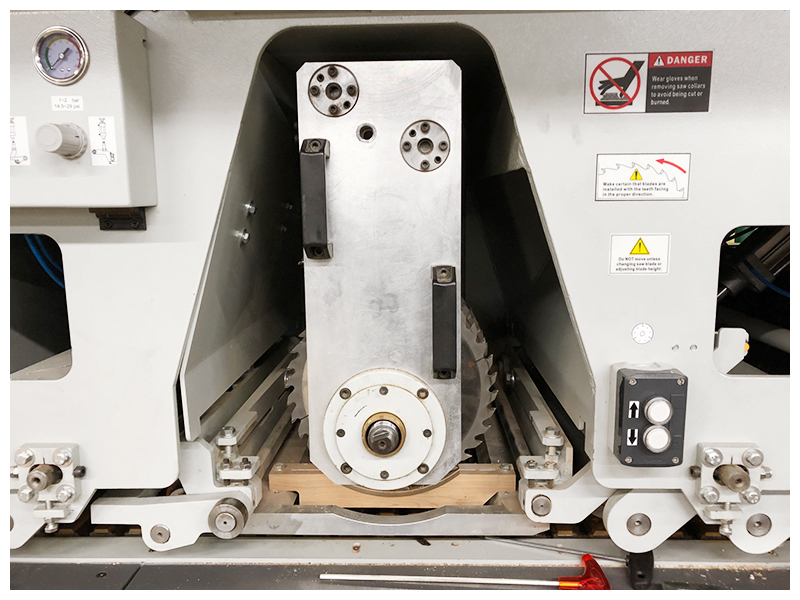

The Quick Rip System from Cameron Automation is a mid-range optimization system for shops ripping 6,000 – 18,000 board feet per shift. It offers the highest yield in the market due to its fenceless design, powerful “Opti-Rip” optimizing software, and multiple moving blade technology in a few different model saws. Non straight boards are handled just as effectively as straight boards and the net result is lower raw material costs. Unlike other systems, the Quick Rip is fenceless and has Auto Skewing for achieving highest possible yield. The sensors read the width, the length, and the shape of the boards. If a board has crook or taper, the software can determine if the board should be skewed for higher yield. If so, it happens automatically. This adds up to an additional 3% yield over systems with a fence. Quick Rips can be paired with Moving Blade Saws that come with (2), (3) or (4) moving blades depending on your cut bill and lumber. The Cameron Opti-Rip software is written in-house allowing changes, improvements and free upgrades to happen on a regular basis.

Why Cameron Automation Quick Rip System?

- 7 – 10% increase in yield

- Extremely accurate positioning of boards (no yield loss due to misalignment)

- High throughput (10 – 12 or more boards/minute). 17 for flooring (fixed arbor saw)

- Increased operator safety

- Tallies material automatically

- Catalogue each and every board

- Machine ships assembled and is up and running in 1 day

- Moving laser lights for zero setup

- Cameron Quick Rip Infeed with Fenceless, Servo-Driven Board Positioner with Extremely High Accuracy

- Multiple Moving Blade, Multiple Fixed Blade Setups

- Completely Integrated Software Package

- Automatic Movable Blade Positioning by the Cameron Software

- Highest board yield on the market

- Industry leading features with the Auto-Skew and Over/Under design.

- Powerful Software to help improve your business and make you more profitable.

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.