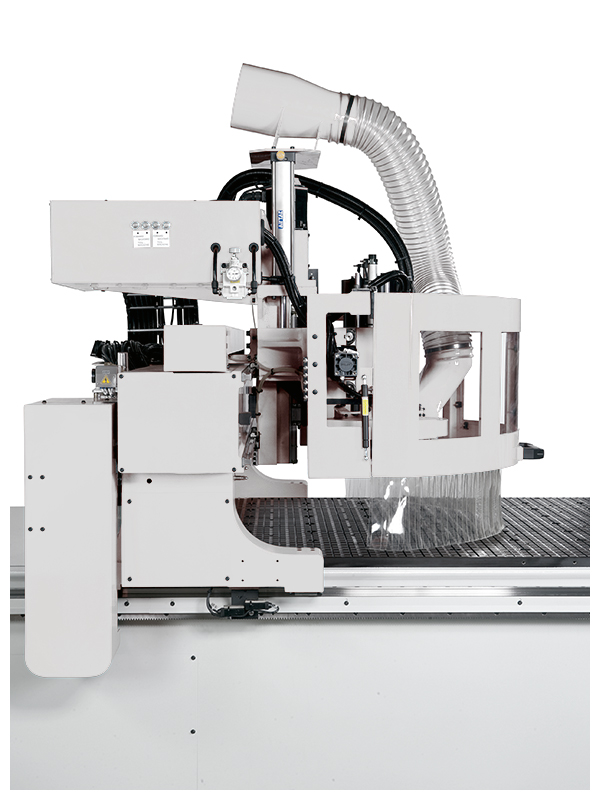

High-performance nesting CNC router for maximum output.

The Anderson Selexx Series CNC Router has been developed specifically with higher production CNC router requirements demanding the utmost precision and accuracy, all within a cost-effective investment. The Selexx is the ideal CNC router for nesting applications as it is packed with standard and optional features to maximize output.

Why Anderson Selexx Series CNC Router?

- A robust machine design combined with powerful features provides faster processing speeds to meet today’s manufacturing requirements.

- Offering nested panel processing at a competitive price, the Selexx Series can process up to 50 sheets of nested cabinet parts a day.

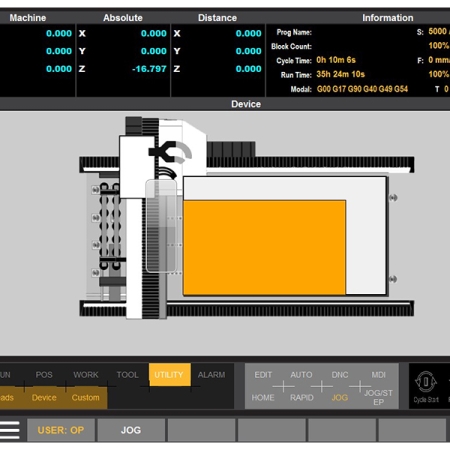

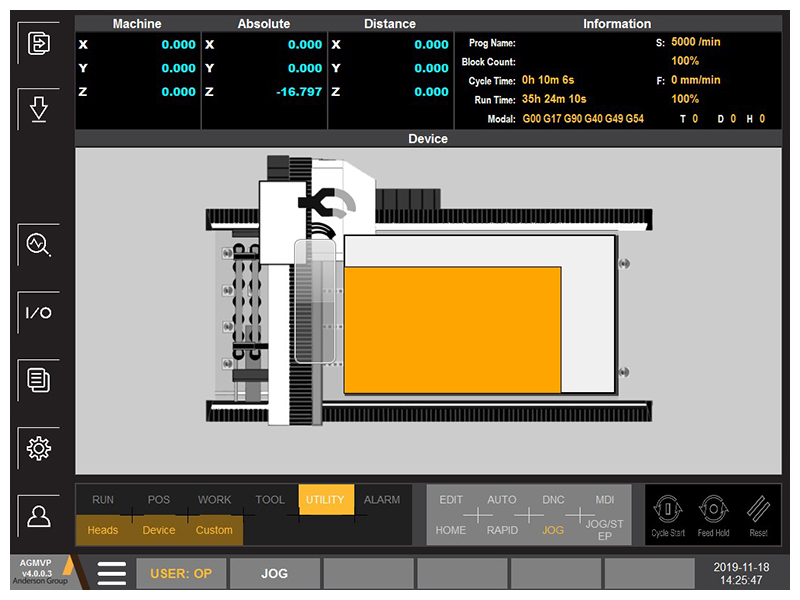

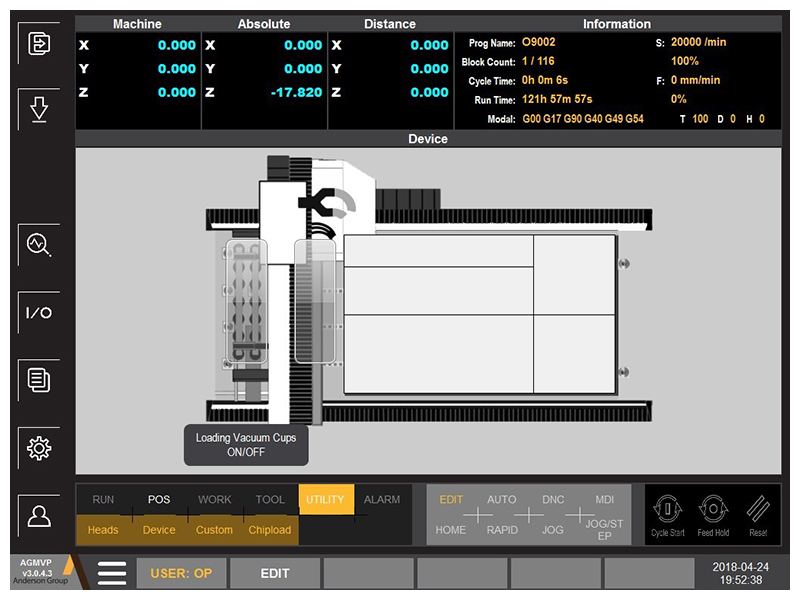

- With a new graphic user interface that will simplify operator tasks, the Anderson Selexx Series offers the reliability of a FANUC control with the ease of use of a PC.

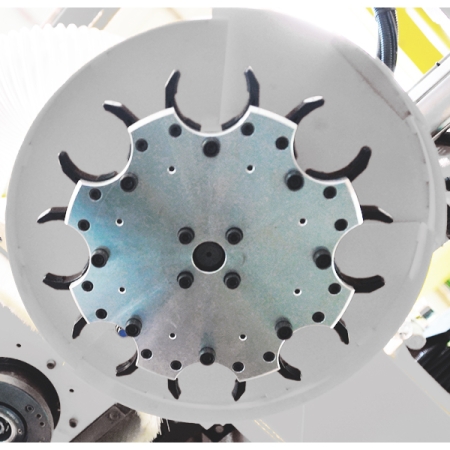

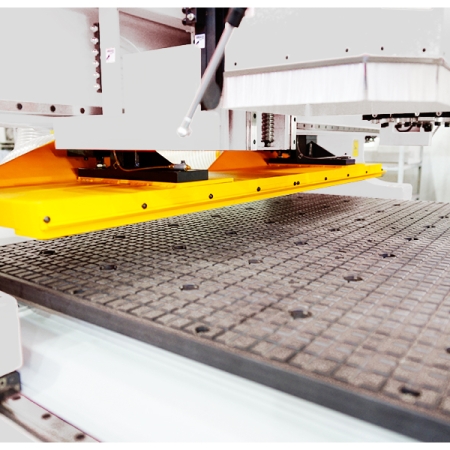

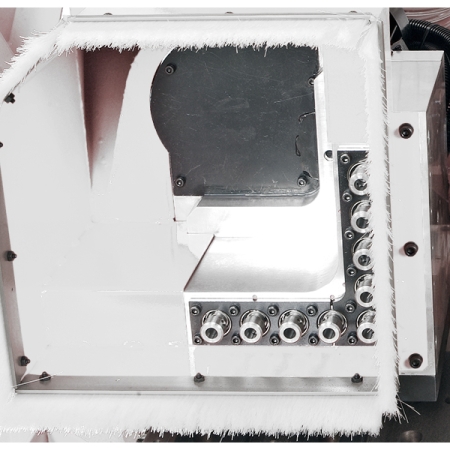

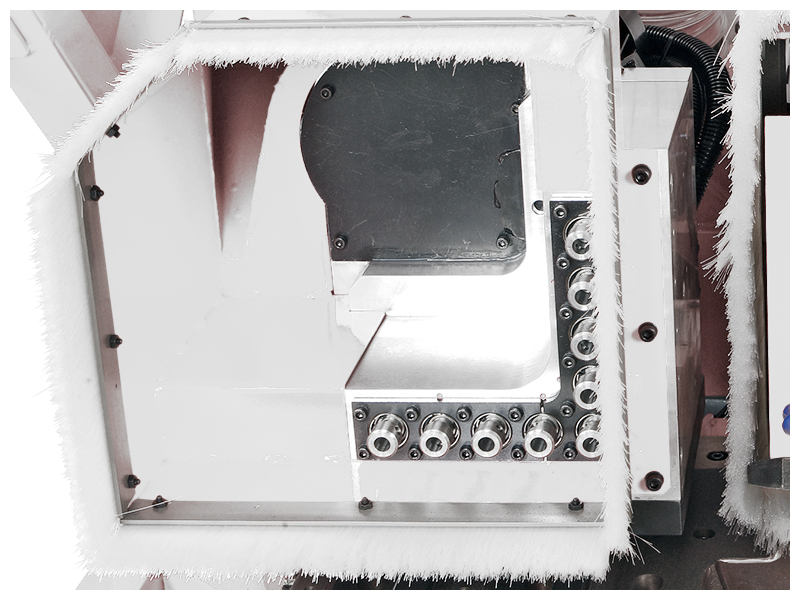

- Efficiency is the key to looking at the powerful features that come standard on the SELEXX, including onboard 8-position tool changer, multi-spindle boring head, auto tool touch off, and material push-off unit.

KEY ADVANTAGES

- Industrial design with cast iron gantry for superior cutting speeds & cut quality.

- Fully versatile CNC machine with HSK electro-spindle, dynamic ride-along tool changer, and drilling head, which are optimum for CNC nesting applications.

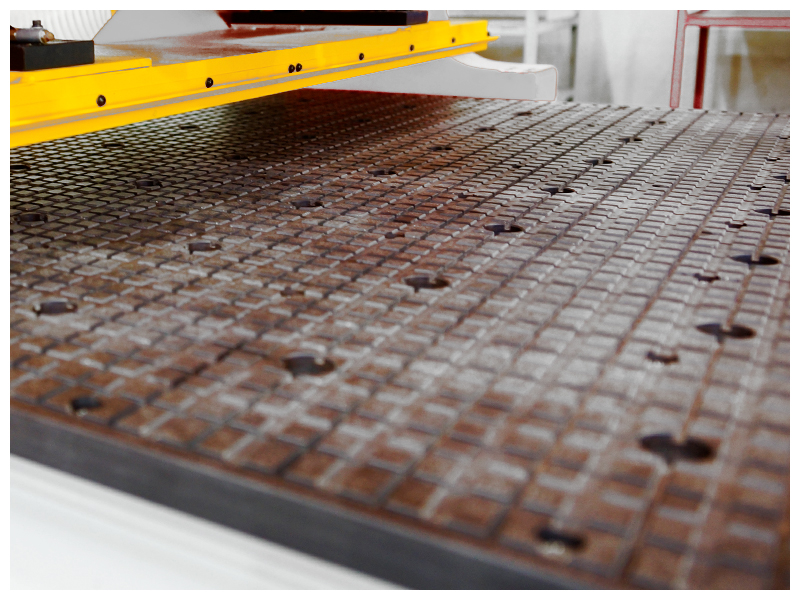

- Superior vacuum holds down using its highly efficient vacuum plenum design.

- Available in three versions with either 4’x8′, 5’x10′, or 5’x12′ table design.

KEY FEATURES

SPECIFICATIONS

SERVICE

*Akhurst Machinery Ltd. is the exclusive distributor for Omnitech Systems / Anderson in Canada. For US inquiries, visit www.andersonamerica.com

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.