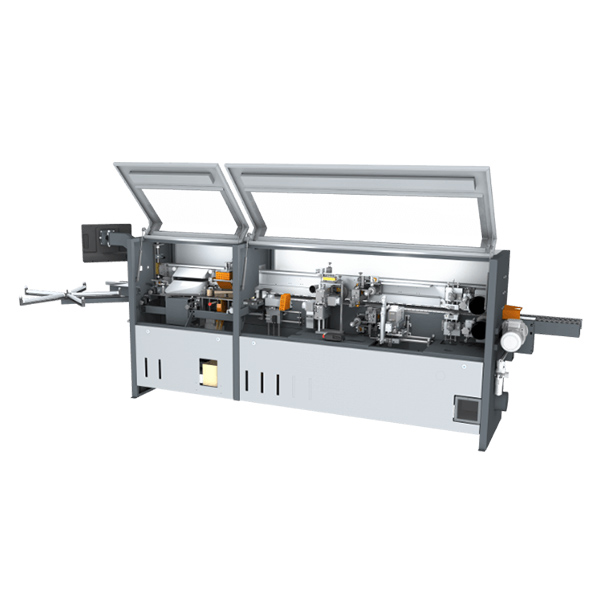

A high-performance all-in-one edgebander.

The Altendorf F5 NEXT Edgebander is the ideal edge banding solution for the small to mid-size cabinet shop looking for a versatile machine to produce high-quality cabinet components and cabinet doors with nearly invisible glue joints. The diamond pre-milling cutterheads produce a precise edge quality which ensures a tight and virtually seamless bond. The quick-change glue pot provides high flexibility allowing for the use of EVA and PUR glues in addition to fast changeover between different colours of glue.

Why Altendorf F5 NEXT Edgebander?

- Engineering excellence blending high-performance traits with unbeatable outcomes. The F5 NEXT guarantees premium edge finishing results with features unmatched in a machine of its class.

- A flexible edge bander for producing unparalleled edge finishing on cabinet components, cabinet doors, and more.

- The F5 NEXT comes equipped with quick-change features, which allow for lightning-quick changeover between various edge tapes and glues.

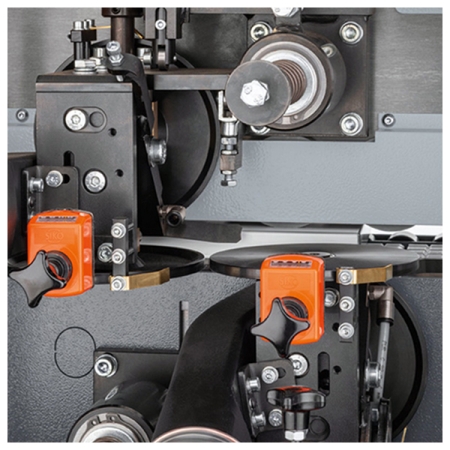

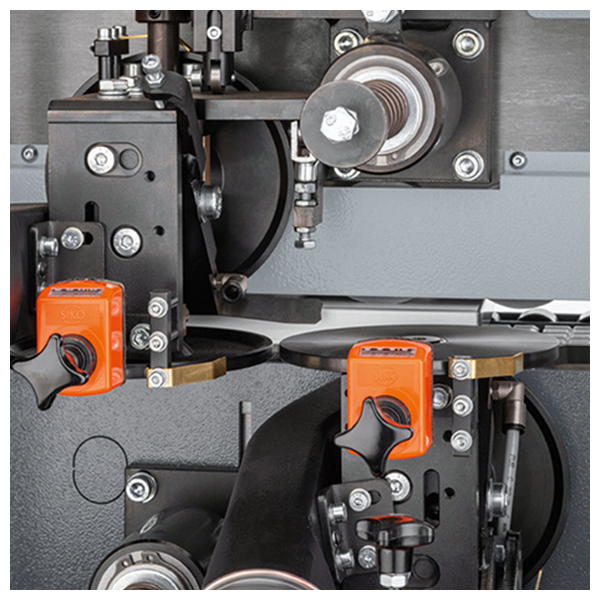

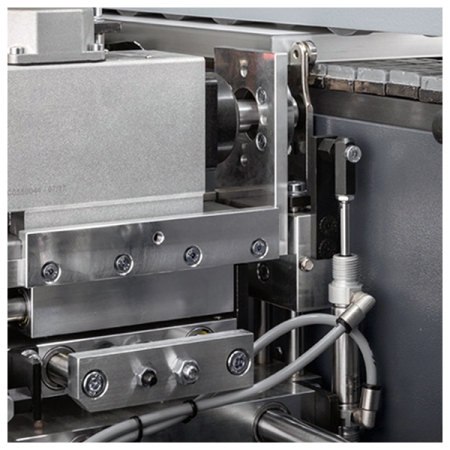

- Compact machine design is packed with features including pre-milling, end trimming, edge trimming, radius scraping, corner rounding, glue scraping, & buffing

- Pneumatic quick adjustment of the edge detail from straight to chamfer to radius

- User friendly 15” touch screen control capable of storing up to 10 programs

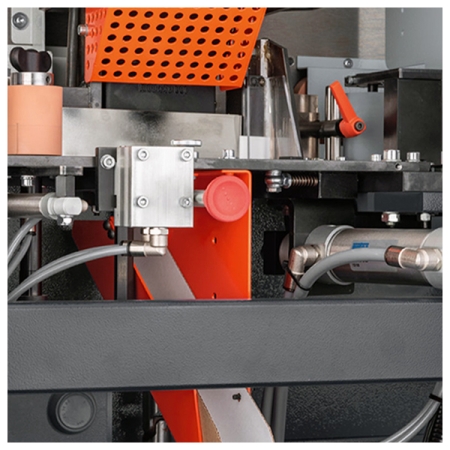

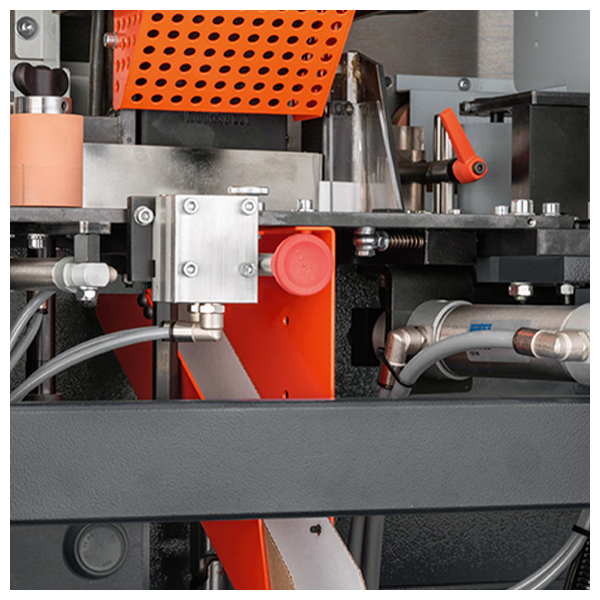

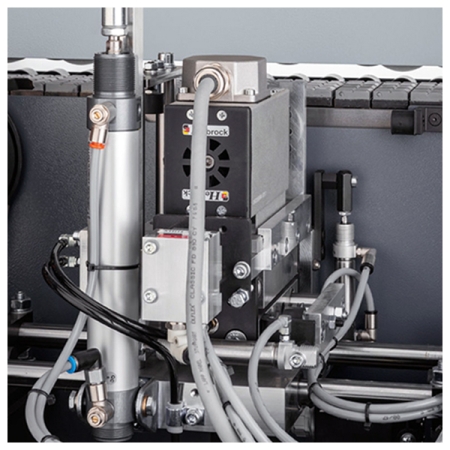

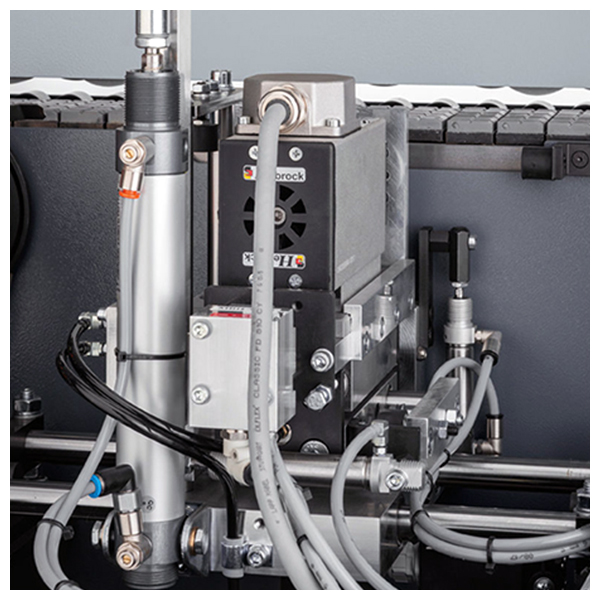

- Quick change glue pot which can run EVA or PUR glue

- Optinal additional glue pot can be interchanged quickly for running different glues or different colours in minutes

- Fast heat-up time of approximately 3 ½ minutes

- Compact machine design with optional casters to maximize valuable floor space when the machine is not in operation

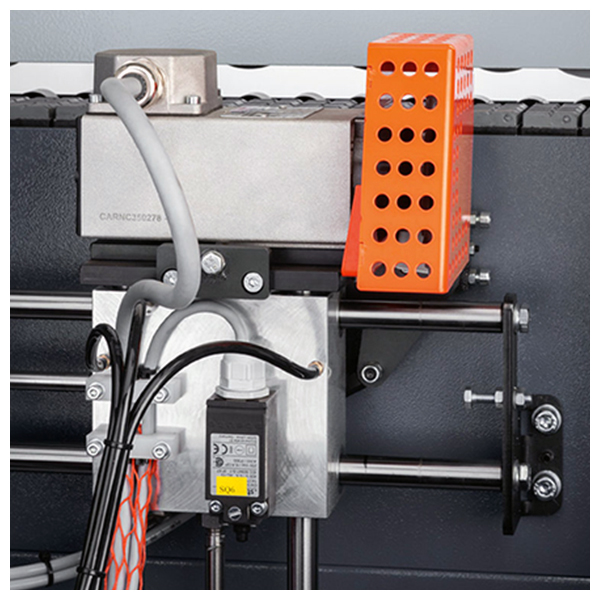

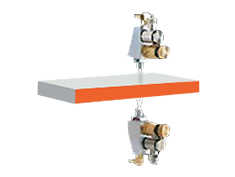

- Optional spray systems for edge and panel surface protection & cleaning

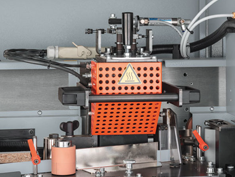

Pre-milling for Edgebanders.

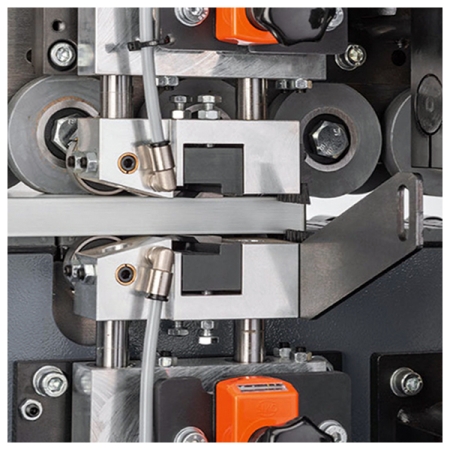

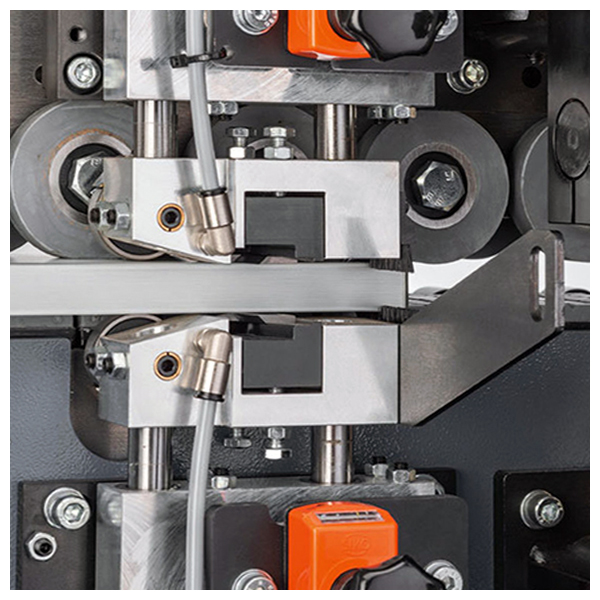

Machinery SolutionsMore often today you are finding features on smaller edge banders that initially were exclusive to larger, higher production machines. One of those features is pre-milling. Pre-milling consists of two counter-rotating cutterheads which are designed to mill the edge of the panel prior to applying the edge banding material.

Proper edgebander maintenance.

Machinery SolutionsEdgebanders are one of the more complex machines in operation in most cabinet and millwork shops. The maintenance however is imperative to the performance and reliability of the machine. Without it you can experience a poor edge quality which will result in hand finishing and defects and worst of all significant down time and expense […]