Low cost edgebander return conveyor.

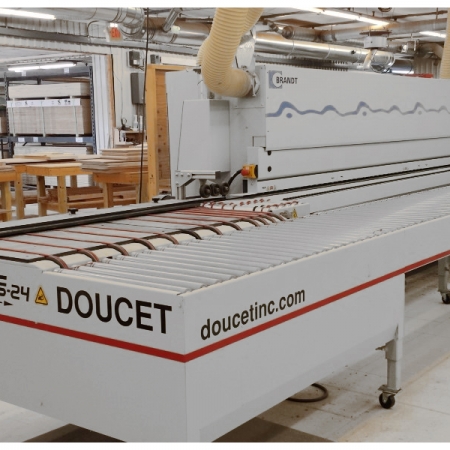

The Doucet XPRS Return Conveyor’s low cost and smaller footprint make it the perfect choice of small to medium size cabinet makers.

The XPRS Return is specially designed to be used with smaller edgebanders. Its low cost and tiny footprint make it a perfect choice for small to medium size cabinet makers. At last an Edgebander Return that will carry your business to a higher level of profitability, even in a part-time operation.

Why Doucet XPRS Return Conveyor?

- Available in right or left hand return configuration

- Features 24″ or 36″ wide receiving modules and return conveyors

- Standard module length is 60″, return length is proportionate to the length of the edgebander

- Power requirement is 110 volts – single phase – 15 amps service, no compressed air is required

- PVC Rollers are individually driven by welded urethane belts

OPERATING PRINCIPLE

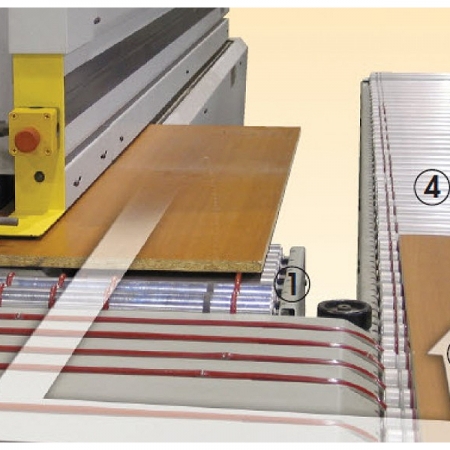

- Feed rollers, driven by a variable speed motor, from 0 to 60 ft/min, guide the part onto the receiving module.

- A set of top rollers prevents larger panels from tipping down while entering the receiving module.

- Polymer belts side-shift the panels to the return rollers quickly and efficiently.

- The return rollers are 2″ lower than the pass height of the edgebander, so that parts can travel in opposite directions without interference.

- The transfer process occurs on a continuous basis.

OPTIONS

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.