Unparalleled performance, flexibility, and reliability in sliding table saws.

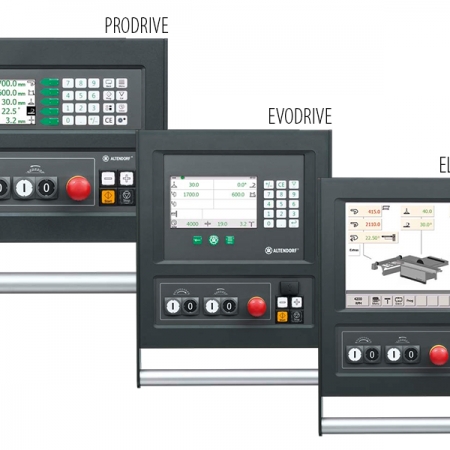

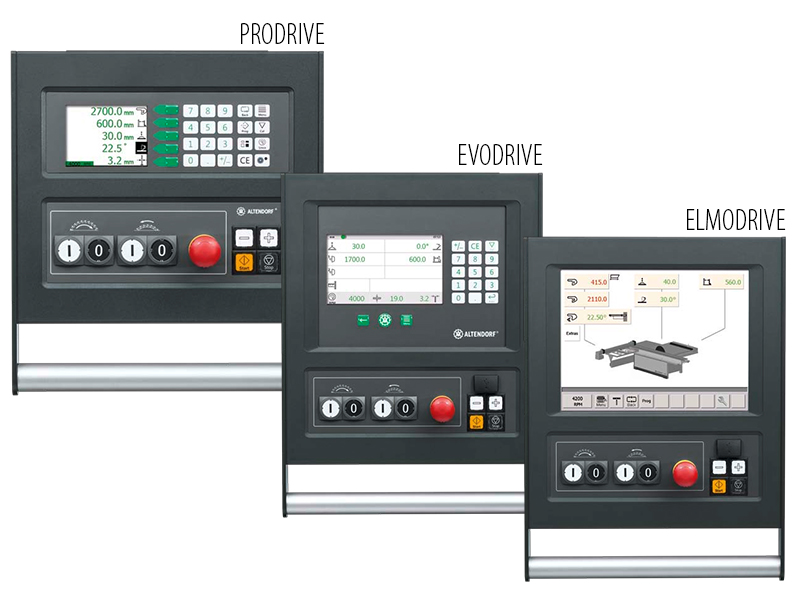

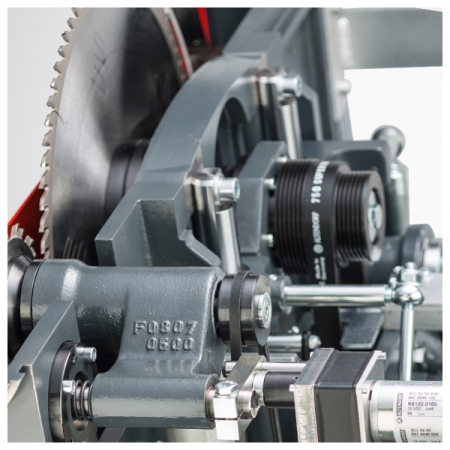

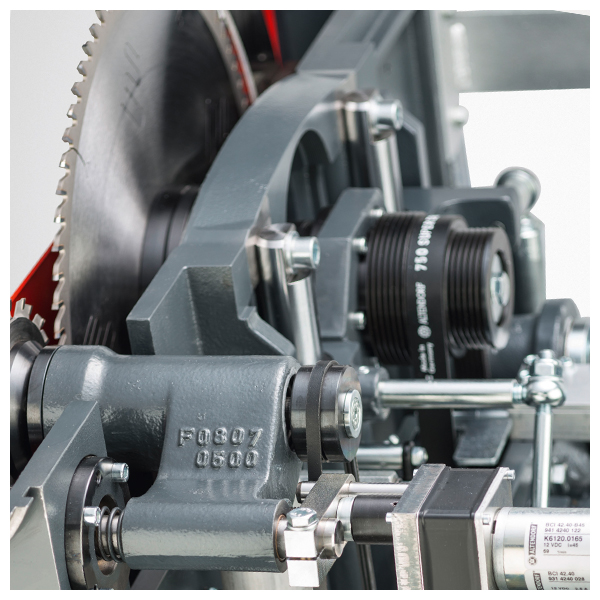

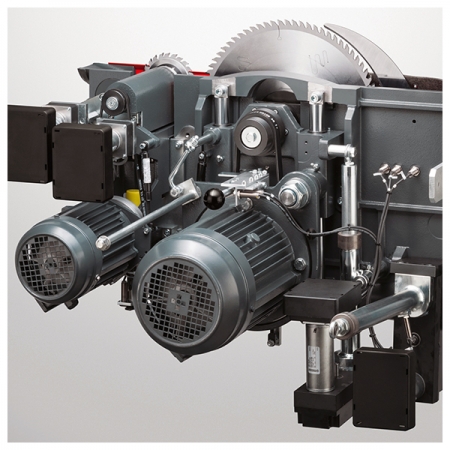

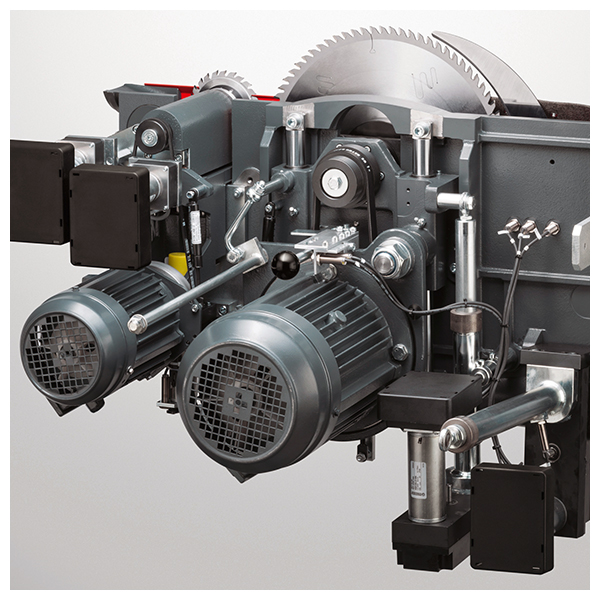

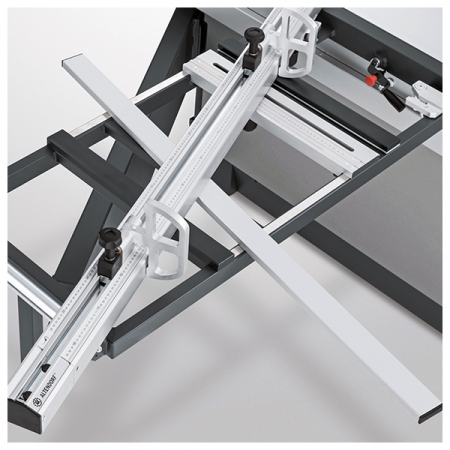

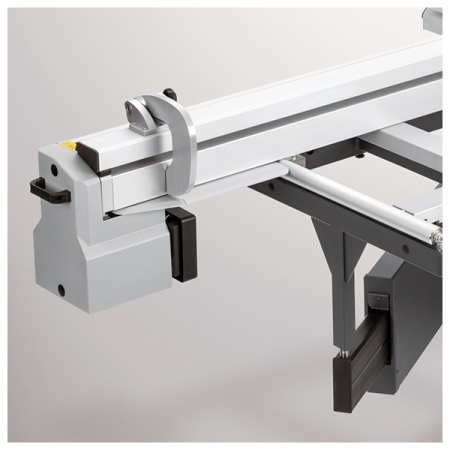

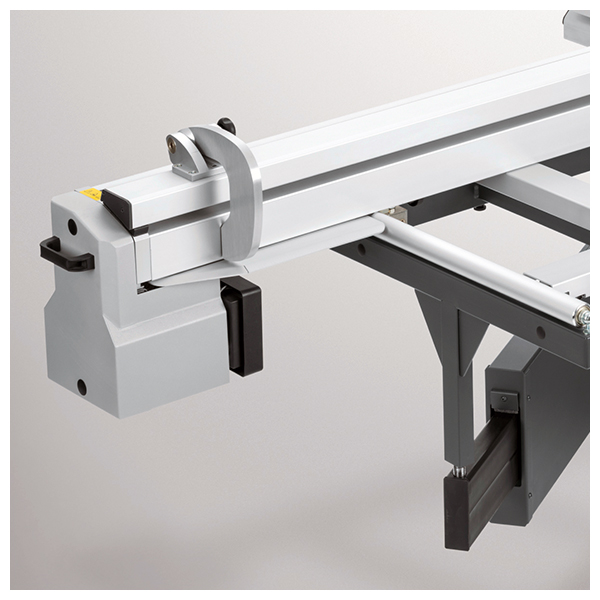

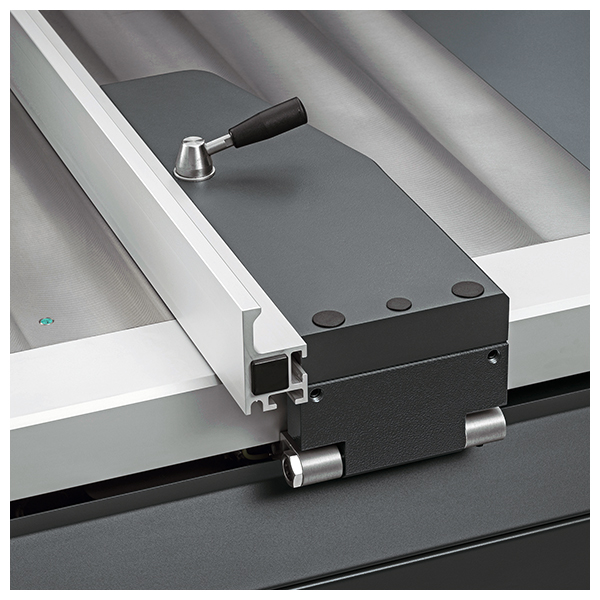

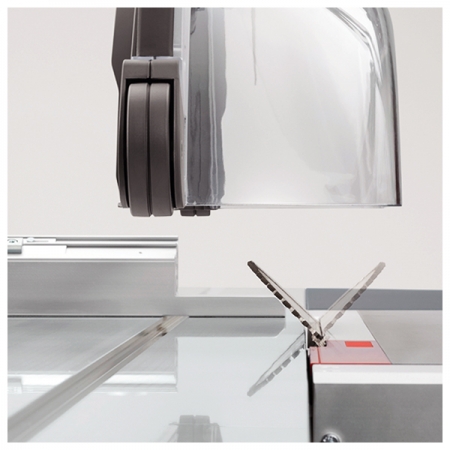

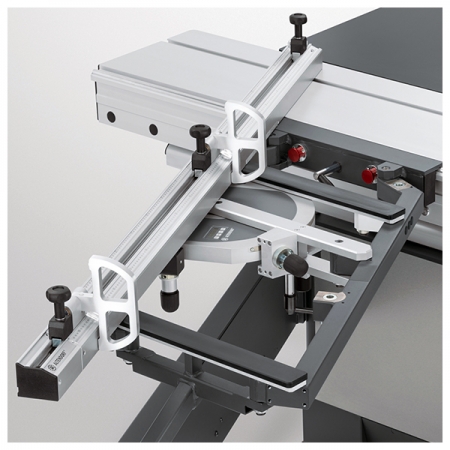

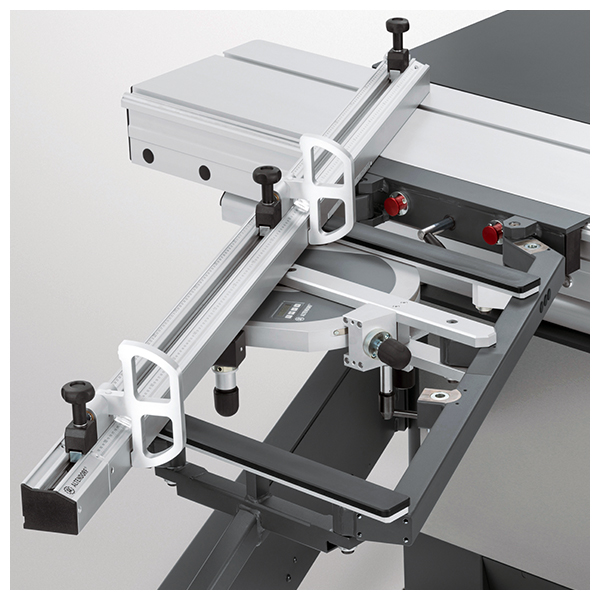

The new Altendorf F45 Sliding Table Saw is a masterpiece of technology and design. The comprehensively redesigned machine frame combines unprecedented torsion resistance with extremely low vibration levels. Simultaneously, the smooth front and clear foot space on the floor enable you to operate closer to the machine and the workpiece. The famously smooth-running sliding table, which has received several design tweaks, remains the undisputed benchmark for precision cutting and minimal maintenance. Complementing these winning features is the eye-level control unit, with which you determine the height and tilt of the saw blade plus, depending on your choice of control package, speed, and other functions. The crisp new industrial design underlines the distinctive quality of the Altendorf brand, melding characterful design and timeless aesthetics.

Why Altendorf F45 Sliding Table Saw?

- A masterpiece of technology and design. The F45 is engineered with you in mind providing uncompromising precision along with virtually unlimited configurations to suit your unique needs.

- The perfect blend of design, precision, and flexibility from the inventor of the sliding table saw. Since 1906 Altendorf has been at the forefront of cutting technology.

- Accuracy and precision every time, customized for your needs with programmable features for repeatability time after time with a user-friendly eye-level control panel.

- Industry-standard for quality, rigidity, and reliability.

- No more compromises: With three control interfaces and a wide range of optional equipment, the F45 can be configured for your specific needs.

- Legendary smooth-running Altendorf sliding table is also the benchmark for the new F 45 sliding table saw when it comes to precision cuts and freedom from maintenance.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.