Unparalleled performance, flexibility, and reliability in sliding table saws.

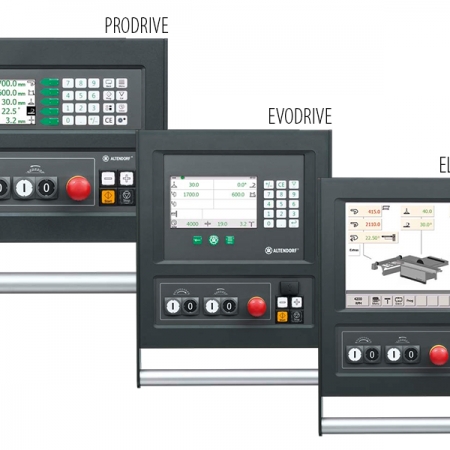

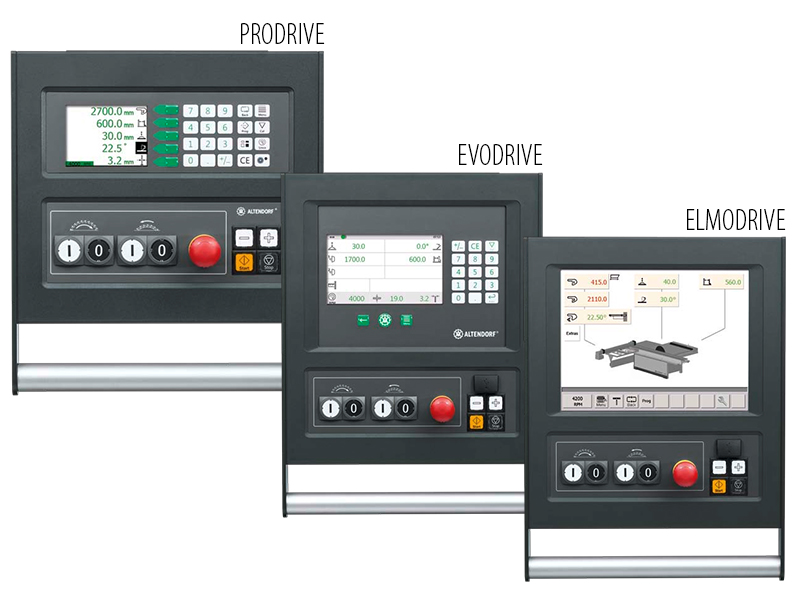

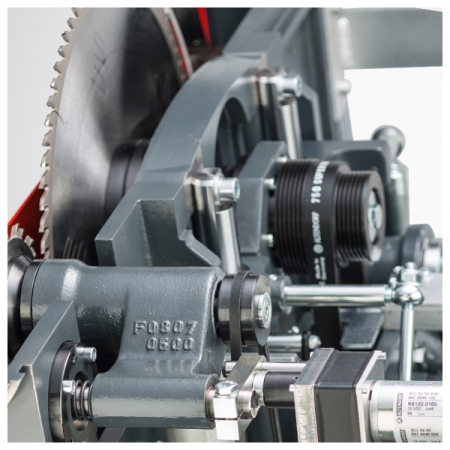

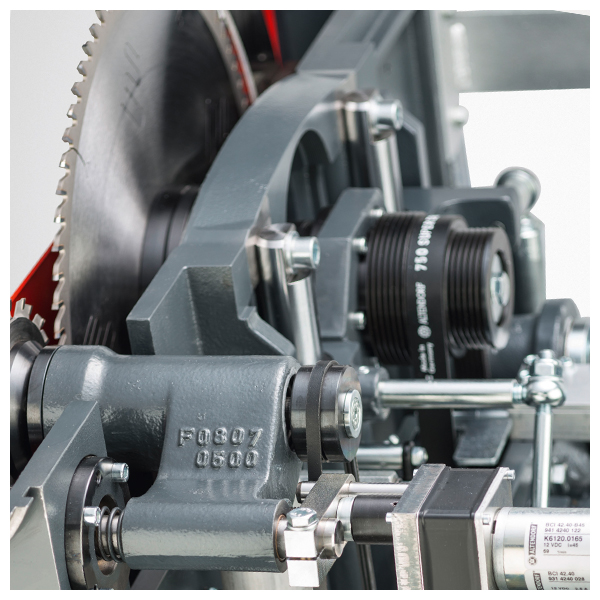

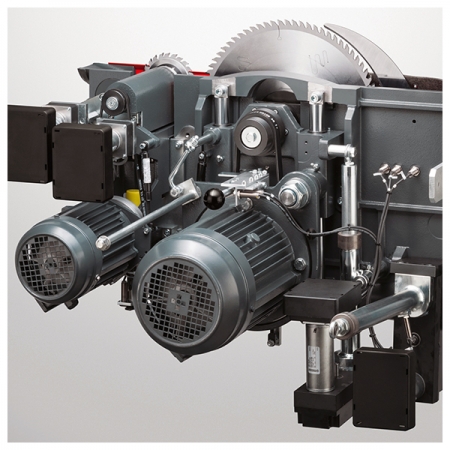

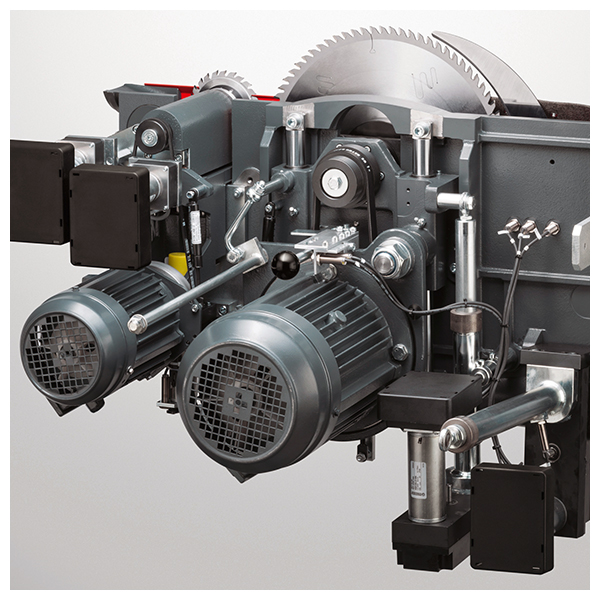

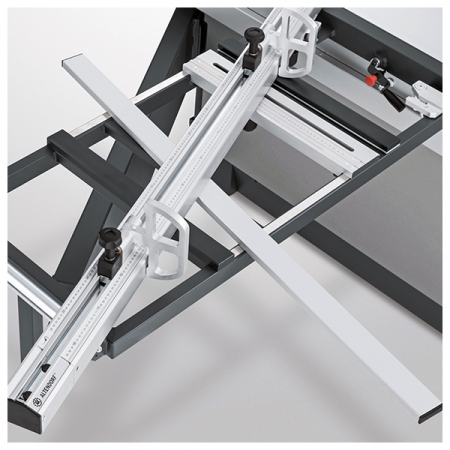

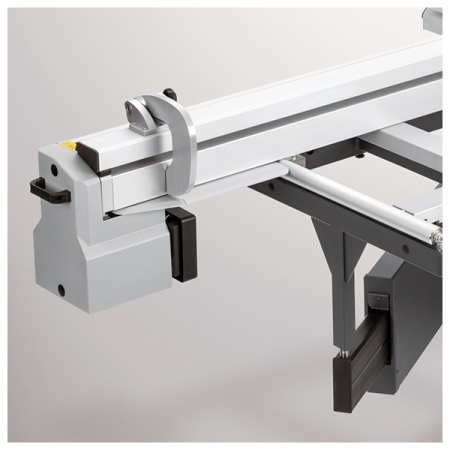

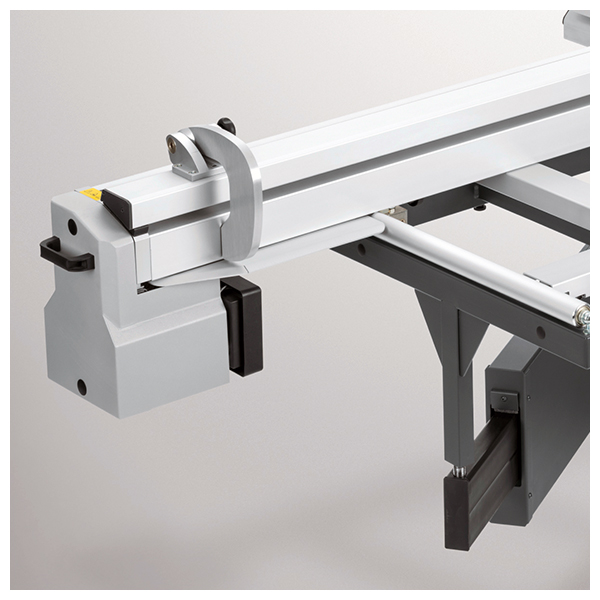

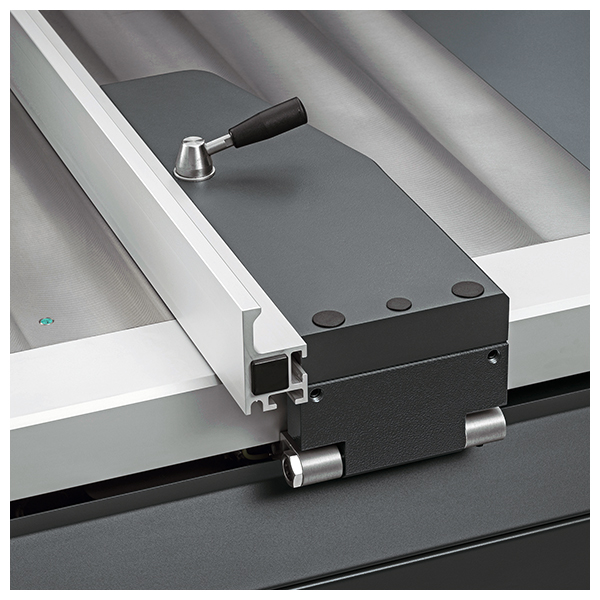

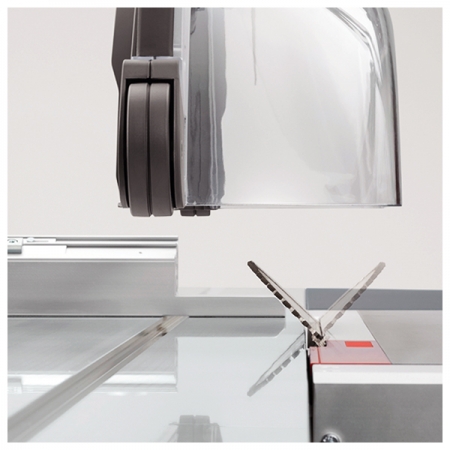

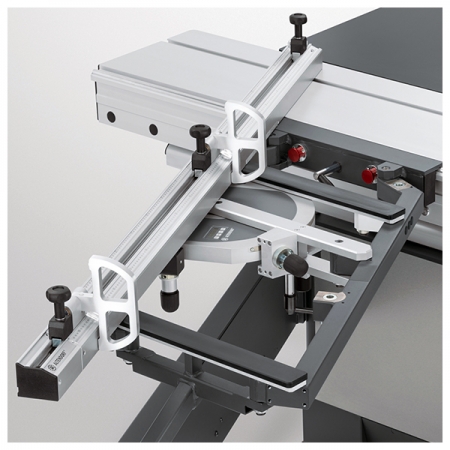

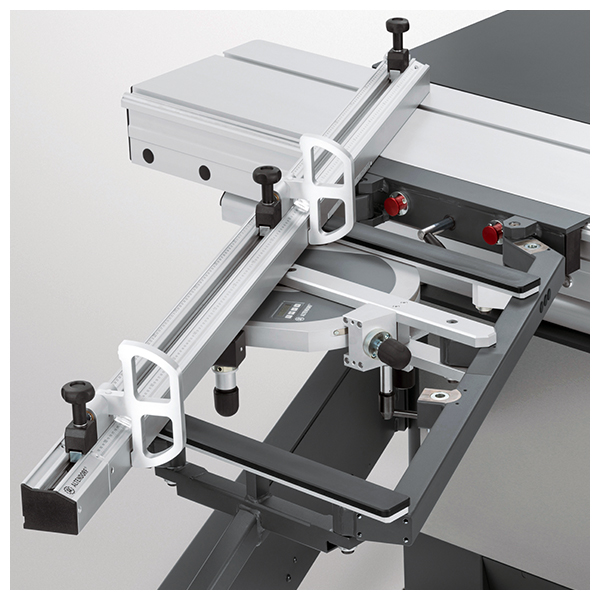

The new Altendorf F45 Sliding Table Saw is a masterpiece of technology and design. The comprehensively redesigned machine frame combines unprecedented torsion resistance with extremely low vibration levels. Simultaneously, the smooth front and clear foot space on the floor enable you to operate closer to the machine and the workpiece. The famously smooth-running sliding table, which has received several design tweaks, remains the undisputed benchmark for precision cutting and minimal maintenance. Complementing these winning features is the eye-level control unit, with which you determine the height and tilt of the saw blade plus, depending on your choice of control package, speed, and other functions. The crisp new industrial design underlines the distinctive quality of the Altendorf brand, melding characterful design and timeless aesthetics.

Why Altendorf F45 Sliding Table Saw?

- A masterpiece of technology and design. The F45 is engineered with you in mind providing uncompromising precision along with virtually unlimited configurations to suit your unique needs.

- The perfect blend of design, precision, and flexibility from the inventor of the sliding table saw. Since 1906 Altendorf has been at the forefront of cutting technology.

- Accuracy and precision every time, customized for your needs with programmable features for repeatability time after time with a user-friendly eye-level control panel.

- Industry-standard for quality, rigidity, and reliability.

- No more compromises: With three control interfaces and a wide range of optional equipment, the F45 can be configured for your specific needs.

- Legendary smooth-running Altendorf sliding table is also the benchmark for the new F 45 sliding table saw when it comes to precision cuts and freedom from maintenance.

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

When does pre-milling make sense?

Machinery Solutions, Service and SupportOver the past few years, pre-milling has grown in popularity. Pre-milling is the process of machining the edge of the panel prior to applying glue. It ensures optimal edge quality before the application of edge banding, resulting in reduced glue joints and a highly aesthetic edge.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.