One Ton of Output for Every Hour of Operation.

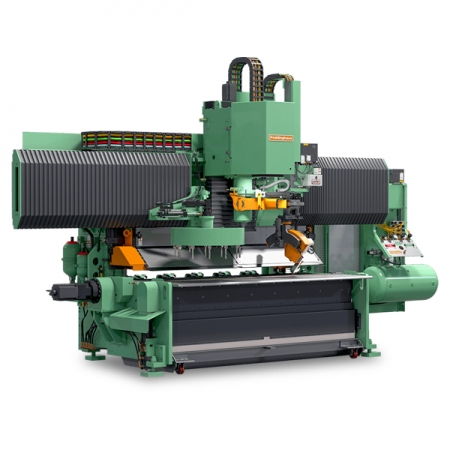

The Pedidnghaus HSFDB-B plate processor is the high speed solution for heavy plate production. This machine encompasses multiple capabilities, provides greater flexibility and maintains complete control of the quality in finished projects.

The CNC plate processing design by Peddinghaus drives material to the operating area of the machine as opposed to bringing the operating area of the machine to the material, like traditional burntable systems. The HSFDB-B provides constant material output to downstream processes.

Why Peddinghaus HSFDB-B Plate Processor?

- Reduce material handling costs with one pass processing – load, process, unload

- Process plate with as little as 5% scrap

- Perform a variety of functions while taking up a minuscule amount of floor space

- Process 1 ton of plate per hour with only 1 operator

- Minimize the potential for human error by eliminating manual measurement

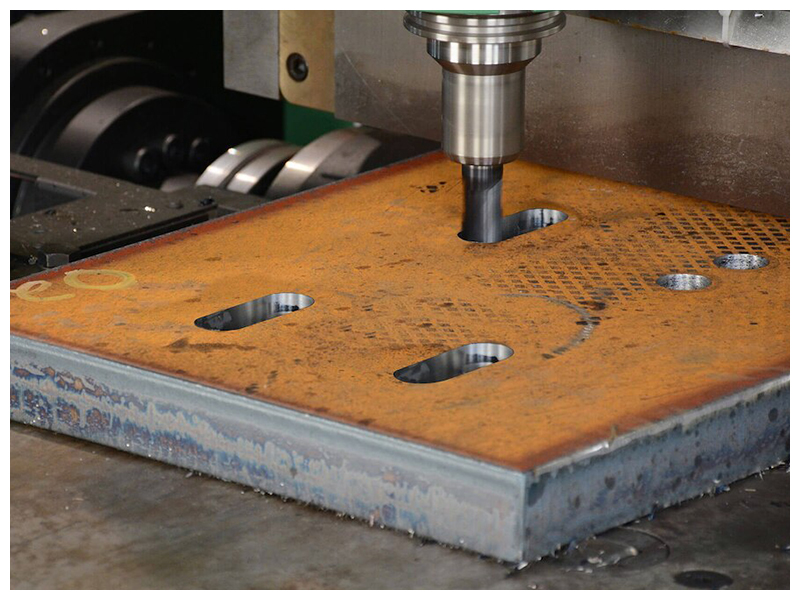

Siemens Spindle Motors

Powered by 48 HP Siemens intelligent spindle motors, the HSFDB-B is outfitted with spindle speeds of up to 2250 RPM. This heightened technology allows for unmatched processing strength and output.

Plasma/Oxy-Fuel Cutting up to 3” Thick Plate

Whether it’s the speed of plasma, or the economy of oxy-fuel, thermal cutting is available in all forms on the HSFDB-B CNC plate processor.

8-Station Tool Changer Enhanced by MQL

The HSFDB-B comes stocked with an 8-station tool holder assisted with the Minimum Quantity Lubrication (MQL) system to prolong tool life.

SignoScript Carbide Scribing

The SignoScript layout marking attachment eliminates human error in manual layout methods. Complete information is maintained throughout blasting, galvanizing and painting processes.

The Side Unloading System

The Side Unloader parts conveyor is designed to allow finished parts to drop directly onto a hardened steel conveyor, delivering them to an ergonomic unloading height at the operator station. The Side Unloader conveyor option transfers parts while the machine is in continuous operation.

Cutting Efficiency

The HSFDB-B CNC plate processor has the capability to perform both edge start cutting and common line cutting techniques. Minimize scrap and consumable wear by getting the most out of your stock plate.

SDS Plate Nesting Software

Peddinghaus plate machines proudly operate with today’s modern nesting software solution, SDS. SDS software allows fabricators to automatically batch nest existing files, edit on the fly or create parts at the control console. Peddinghaus machines are able to take full advantage of common cutline, chain cutting and edge start cutting techniques.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.