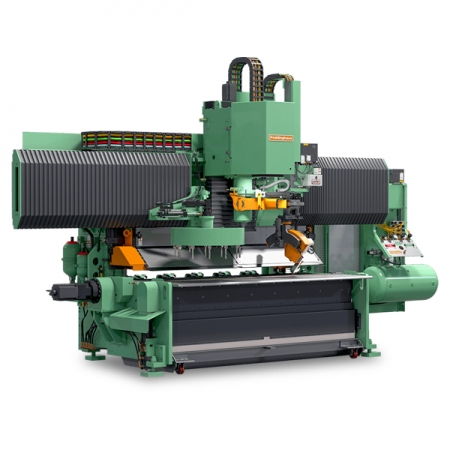

Your Everyday Plate Processor.

The Peddinghaus FPB-1800 High Speed Plate Processor is the ideal machine for fabricators and manufacturers alike. Equipped with the ability to punch, plasma cut, and scribe using the latest in tooling technology, the FPB-1800 combines speed and versatility. The use of high tensile punch dies and the plasma torch assembly allows this machine to process plate in the most efficient way possible.

The streamlined flow of finished parts from stock plate to final assembly is just as critical as drilling, cutting or other ancillary operations. Eliminate unnecessary manual handling with a Peddinghaus plate processing system. This provides unmatched efficiency in all aspects of operation.

Why Peddinghaus FPB-1800 High Speed Plate Processor?

- The FPB-1800 is the solution for supplementary plate cutting and punching

- The machine encompasses multiple capabilities, provides greater flexibility, and maintains complete control of the quality in finished projects

- Drives material to the operating area of the machine as opposed to bringing the operating area of the machine to the material, like traditional burntable systems

- Provides constant material output to downstream processes

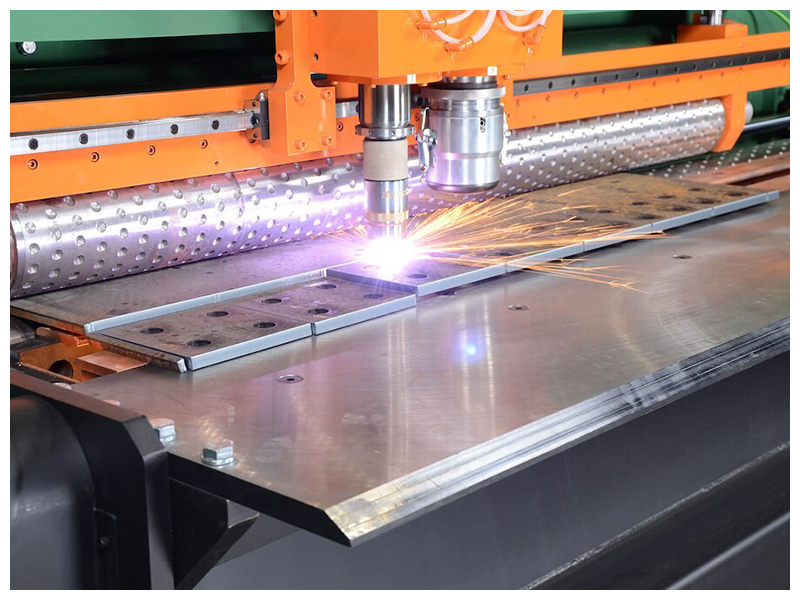

Plasma Cut 1” Thick Plate

When it comes to plate production, the FPB-1800 provides maximum durability with innovative cutting techniques. The FPB-1800 performs flawlessly for processing parts up to 1-1/4″ (25 mm) thick. On average, 80% of shop plate production is 1″ thick material and under.

Efficiently Process with the Triple Tool Punch Press

The most cost-effective way to process holes in steel plate up to 1″ thick is by using the FBP-1800. The proven 177 ton triple tool punch press of the FPB-1800 allows for maximum durability and efficiency. Capable of punching holes up to 1-3/4″ (44 mm) in diameter, and maintaining up to three available punch stations, the FPB-1800 minimizes the need for timely tool changes.

Speed And Versatility Benefits Downstream Production

This CNC plate processing design drives material to the operating area of the machine as opposed to bringing the operating area of the machine to material, like traditional burntable systems. The FPB-1800 provides constant material output for welders and fitters, allowing them to focus on assembling the end-product.

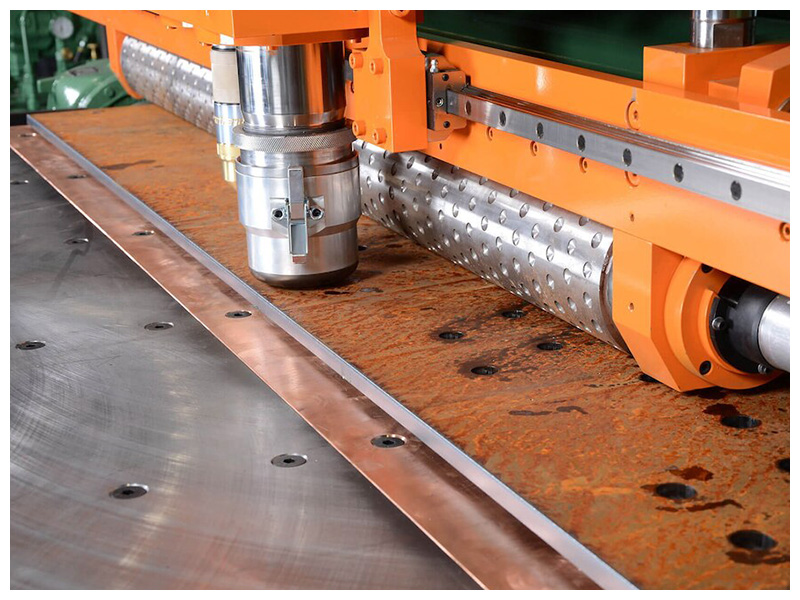

Nonstop Throughput with Roller Feed Measurement

Equipped with the Peddinghaus Roller Feed measurement system, the FPB-1800 maintains contact with the material at all times.

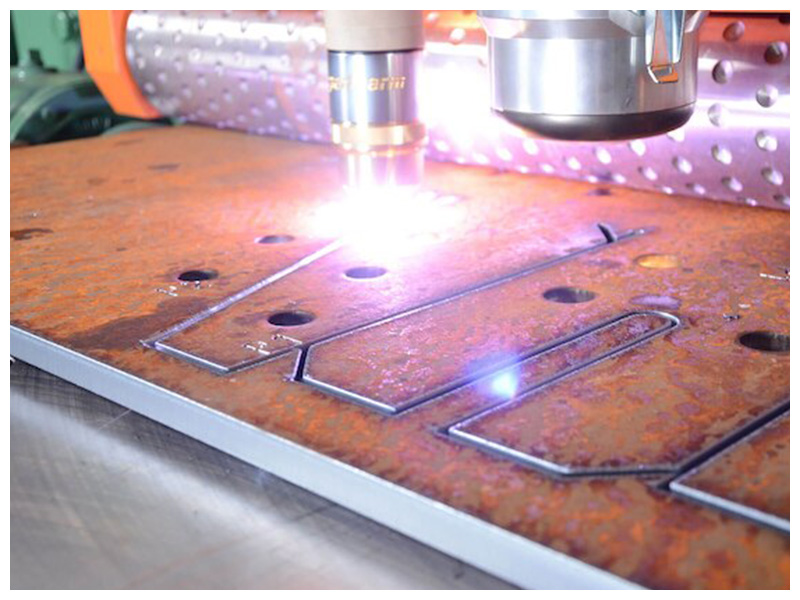

SignoScript Carbide Scribing

The SignoScript layout marking attachment eliminates human error in manual layout methods. Complete information is maintained throughout blasting, galvanizing and painting processes.

The Side Unloading System

The Side Unloader parts conveyor is designed to allow finished parts to drop directly onto a hardened steel conveyor, delivering them to an ergonomic unloading height at the operator station. The Side Unloader conveyor option transfers parts while the machine is in continuous operation.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.