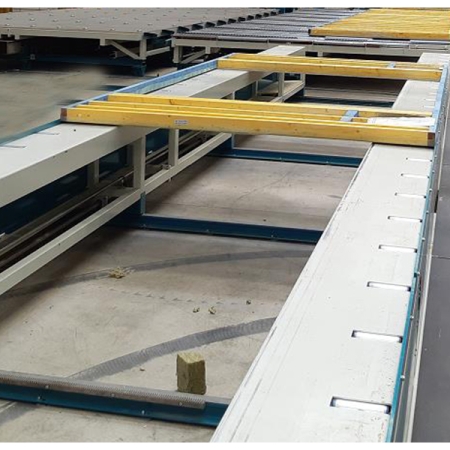

Squaring table for the application of cladding materials to a pre-assembled timber frame wall panel.

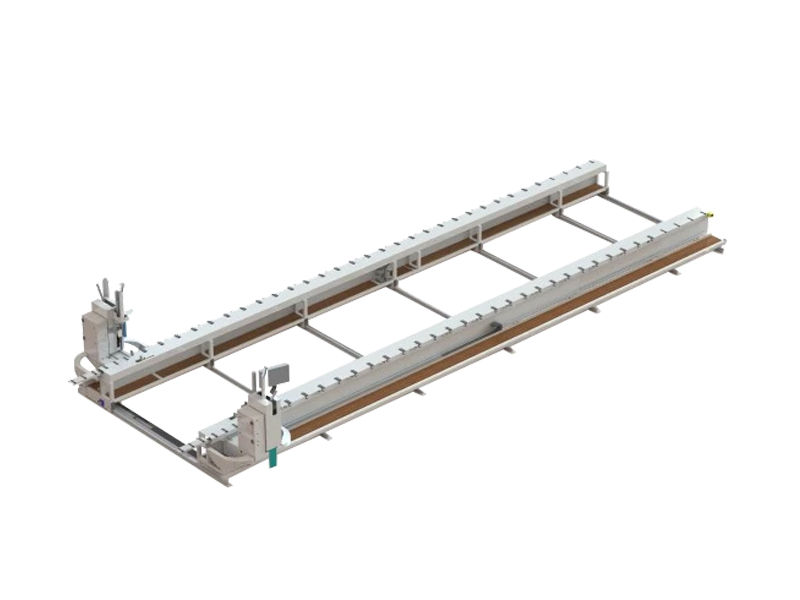

The MBA X-Square Squaring Station for Timber Frame Construction Elements is a basic squaring table, controlled by a PLC, designed for manual boarding tasks or combined with a rail-mounted nailing bridge. Objects can be effortlessly inserted using the convenient pop-up transfer rollers and automatically aligned in both X and Y axes with the 3-point clamping mechanism. Upon completion of all tasks, the finished panel can be released with a simple push-button action and moved to the next station.

Why the MBA X-Square?

- Easy panel transfer system with pop-up transfer rollers

- Width adjustment motorized via rack and pinion with locking system

- 3-way clamping for automatic panel squaring and clamping

- Swing gates for easy access through the line

KEY ADVANTAGES

- Standard 6 m (20 ft) capacity table

- Heavy duty tables with one fixed and one moveable side for the squaring of a pre-ma

- nufactured panel for the application of OSB or Plywood

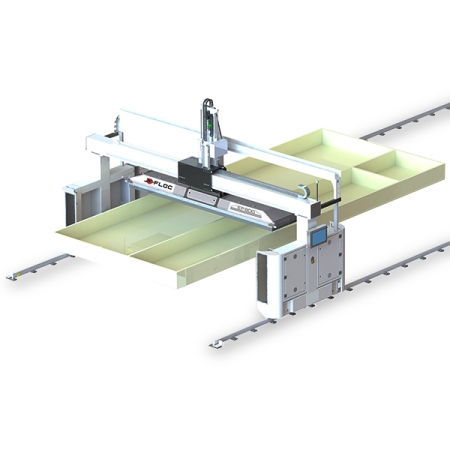

- Can be used for manual operations or paired with a rail mounted nailing bridge

SPECIFICATIONS

ADDITIONAL OPTIONS

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.