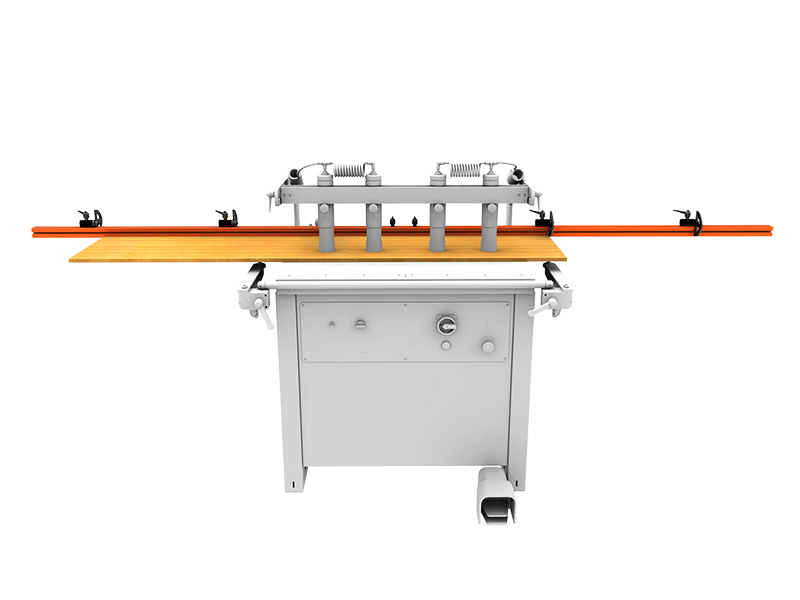

Versatile boring machine for the construction of cabinets and case goods.

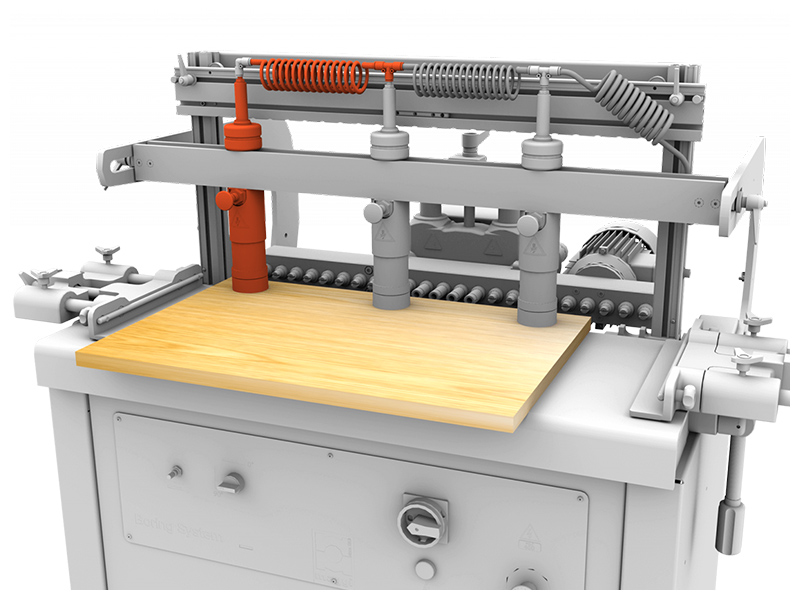

The Maggi System 21 Prestige Construction Boring Machine is a versatile boring machine for the construction of cabinets and case goods performing the functions of line boring, construction drilling, end drilling for dowels and more. It is equipped with a single row of 21 spindles spaced on 32mm. The quick-change chucks allow for quick boring pattern setup. The patented spiral depth adjustment system allows for easy and quick setup for the boring depth according to the various drill lengths. The boring head is rotated from a vertical to horizontal position with a simple pneumatic cylinder and can be set on any angle from 0° to 90°. Equipped with a 3-meter back fence and flip stops and right and left fold away side fences for added flexibility. The System 21 Prestige truly can do it all at an economical price point.

Why Maggi System 21 Prestige Construction Boring Machine?

- 3000mm back fence with (2) flip stops for accurate panel positioning

- Equipped with (21) quick change chucks to allow for fast boring pattern setup and quick boring bit changeover for various operations (5 are starnard, 16 extra are included as per below)

- (3) material clamps safety clamps (2 are standard, 1 extra is included as per below)

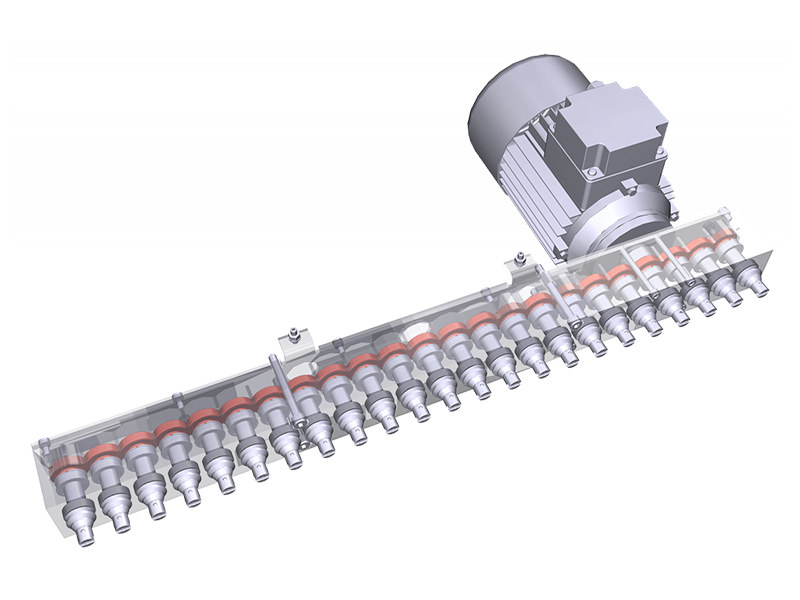

- Powerful 2HP drilling motor

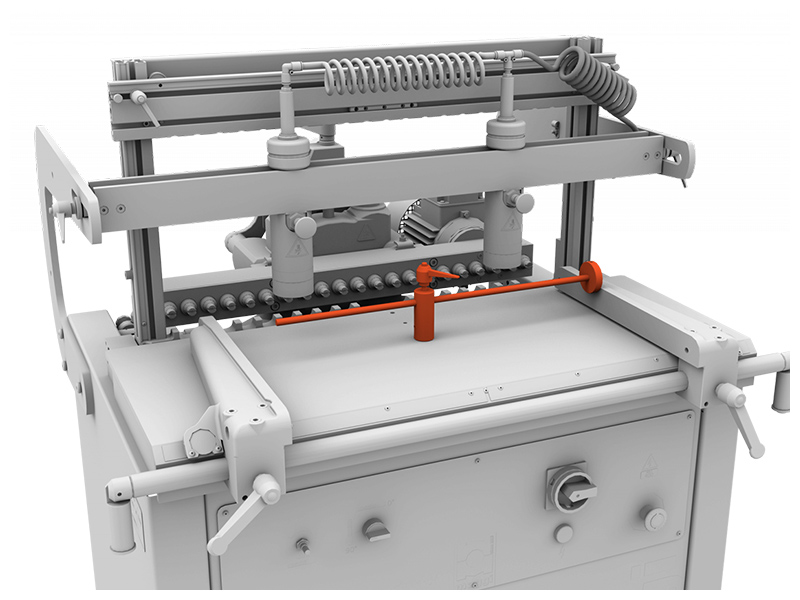

- Patented spiral system for fast and accurate boring depth adjustment

- Pneumatic drill beam rotation from 0 ~ 90° with reference stops

- Adjustable side fences with mechanical digital readouts for fast and accurate adustment

- Accurate positioning of the boring unit to the table with digital readout

- Cast iron table which is precision ground

- Foot actuation for clamping and drilling cycle

- Provincial electrical inspection certification

- Drill bits are not included. Available upon request

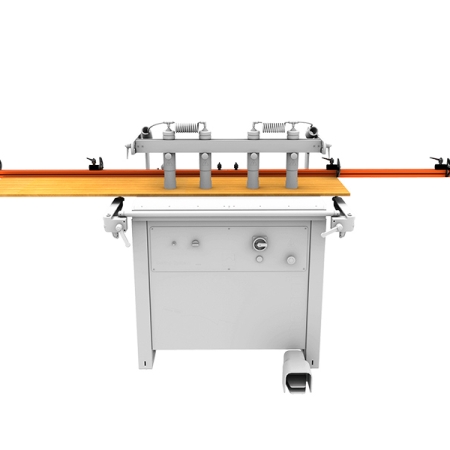

Side Fences

Cast iron side fences are adjustable along a metric bar, with magnifying glass and scale. It always represents a precise reference point for the operator and guarantees the perfect parallelism of the drilling operations.

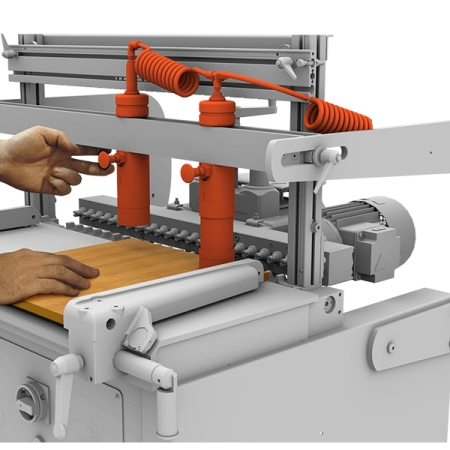

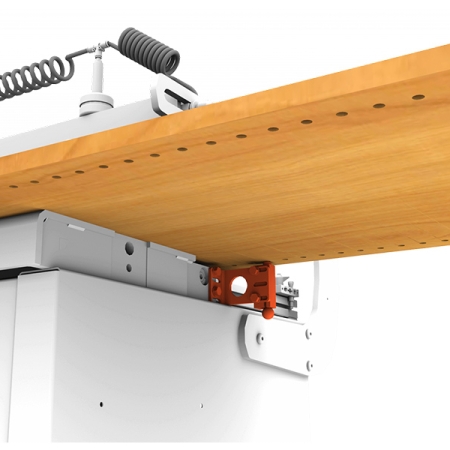

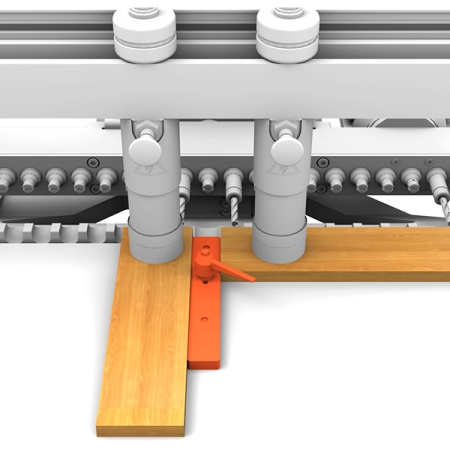

Safe Panel Hold-Down Clamps

The quick-positioning, safety, hold-down clamping units ensure the greatest stability and steadiness of the working piece during the working cycle and the highest accuracy of the drilling process.

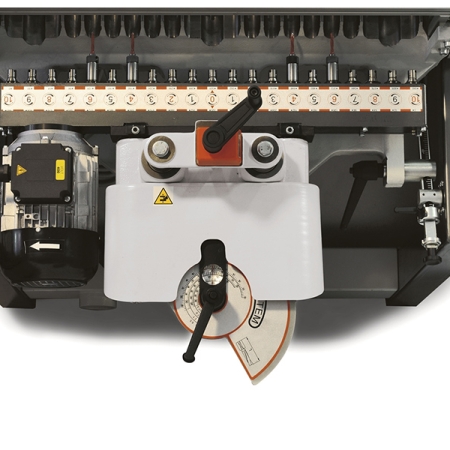

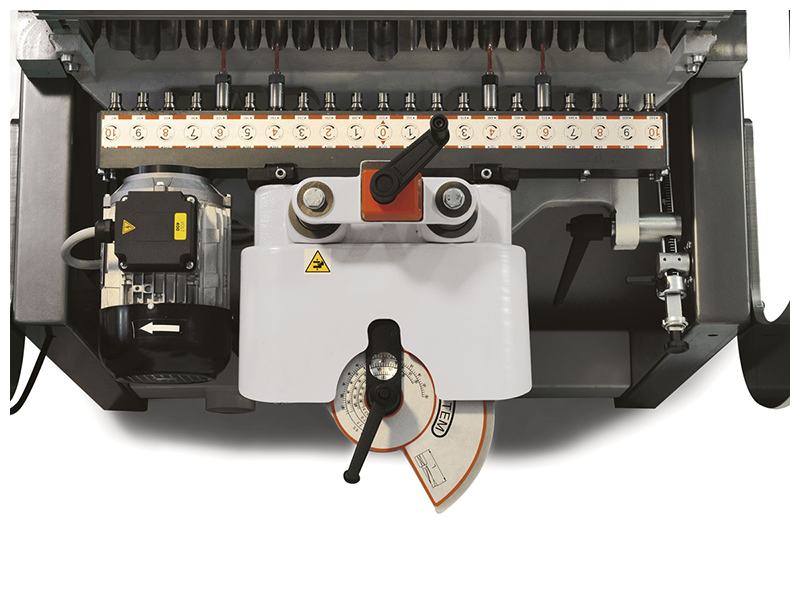

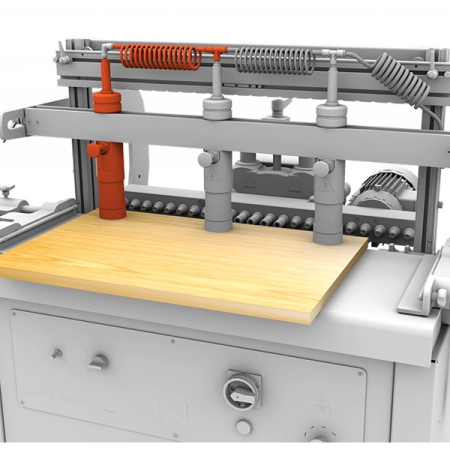

Quick Depth Set-Up

Patented spiral device for boring depth adjustment, allowing an easy and quick set-up on a millimetric scale according to the different drill lengths. A mechanical digital readout is used to accurately adjust the boring head position.

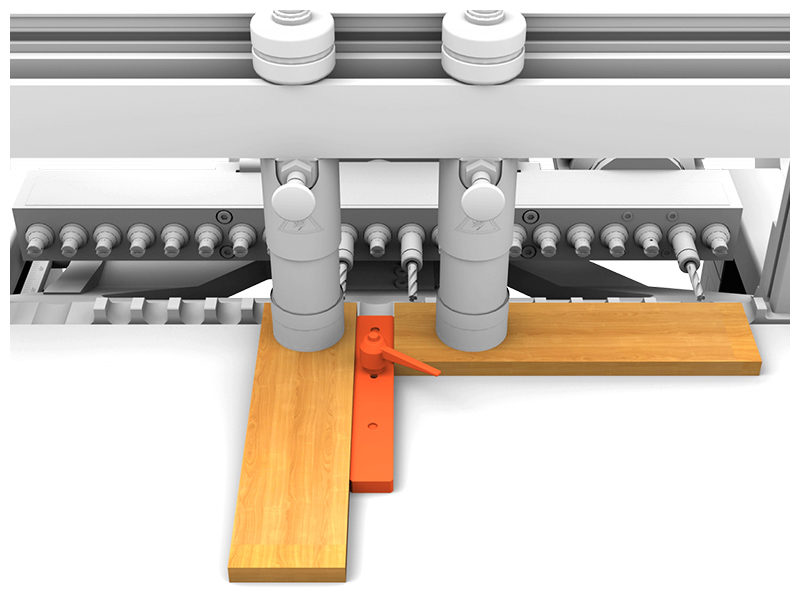

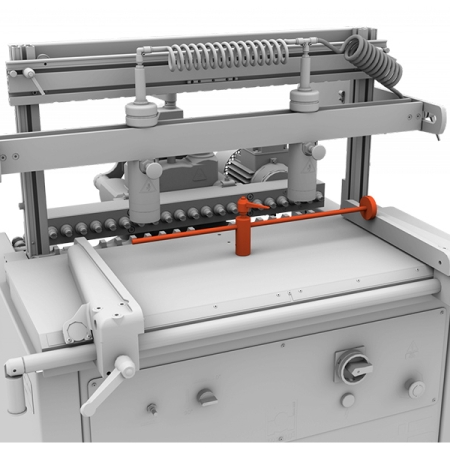

Versatile Tilting Boring Head Adjustment

Pneumatic drill beam rotation from 0 ~ 90° with reference stops. Head can be quickly tilted from vertical to horizontal position and anywhere in between for angle drilling operations.

Quick & Accurate Panel Positioning

Thanks to the two aluminium fences 1500 x 80mm with 2 reference stops. (More are available upon request

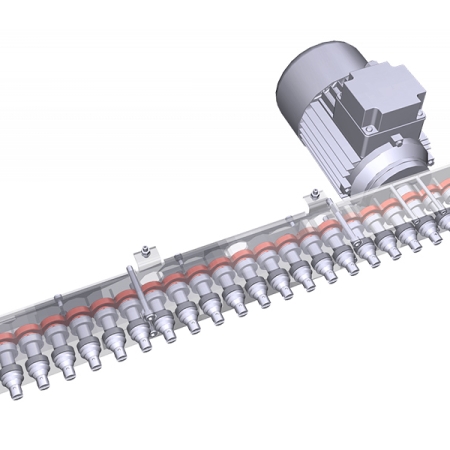

Precision Boring Head

The boring head is made of aluminum while the internal gears are made of rectified steel.

Quick Change Chucks

Comes equipped with a complete set of 21 quick change chucks for fast setup of various boring patterns. The spindles are spaced at 32mm according to the European standard system.

Indexing Pin (Option Included)

The indexing pin allows for convenient continuous line boring operations as it references in the center of a previously bored hole.

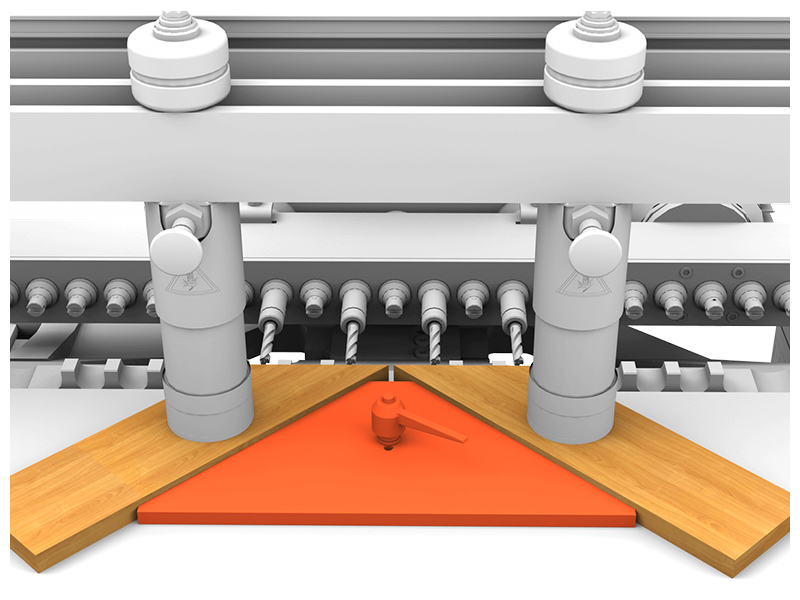

Set of (2) Reference Stops for drilling at 45o and 90o (Option Included)

Ideal for drilling rails, straight and miter frames.

Additional hold-down clamp (Option Included)

To increase the hold-down pressure on the working panel and consequently its stability during the drilling process. N.1 additional hold-down clamp

Gauge for the symmetry of the side fences (Option Included)

For a quick and accurate adjustment of the two side fences on the working table, to obtain the perfect parallelism of the drilling process

Gauge for the symmetry of the side fences (only for BS 21 PRESTIGE)

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.