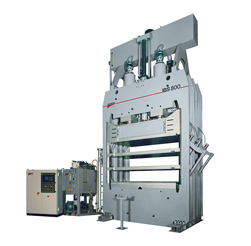

Maximum pressure and parallelism for precisely glued panel production.

The Italpresse XL series hot press is a hydraulic hot press for pressing laminates or veneer onto a substrate. The high efficiency diathermic oil recirculates though the upper and lower platens to reduce pressing time. The industrial design of the press with its massive steel beam frame along with the massive pressing cylinders exert force to ensure the proper bonding of each panel and ensures they are perfectly flat.

Why Italpresse XL Series Hot Press?

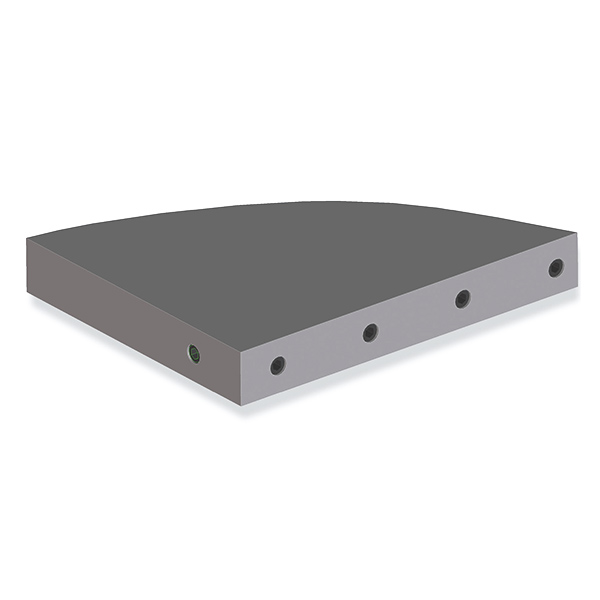

- Wide range of platen sizes available in widths from 1300 to 2200mm and lengths from 1300 to 5200mm.

- Massive steel I-beam structure to withstand high pressures

- Recirculating heating system using diathermic oil for consistent results and fast curing times

- Hydraulic pressure system capable of 50 to 250 tons for superior bonding

- User friendly touch screen interface for simple setting of the press functions

KEY FEATURES

- Welded beams press frame, calculated with high structural safety factor

- Available with single daylight or multi-daylight opening for pressing more than one panel

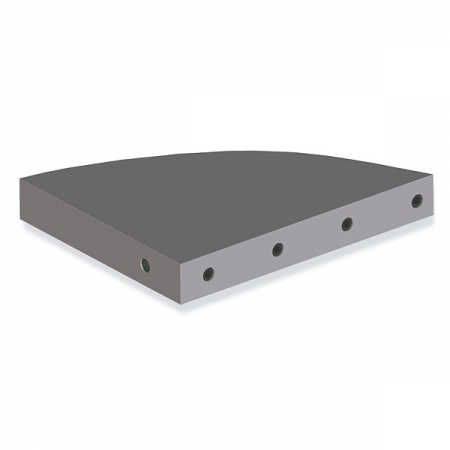

- Frame, moving platen and fixed platen are CNC machined ensure precision

- The moving platen is a fabricated weldment of high thickness steel beams to withstand the pressing tonnage with minimal deflection

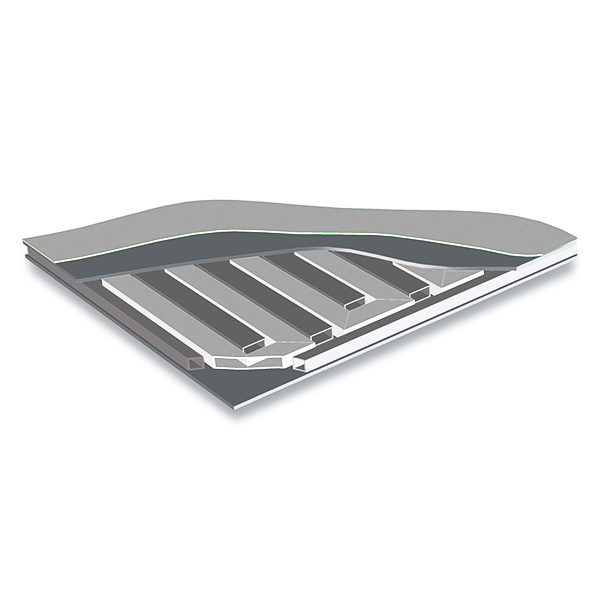

- Available with heating platens constructed with either assembled steel or solid steel to suit your pressing requirements and budget

- Platens can be covered with Mylar for easier cleanup between pressing operations

- Available with 4 to 10 hydraulic clamping cylinders

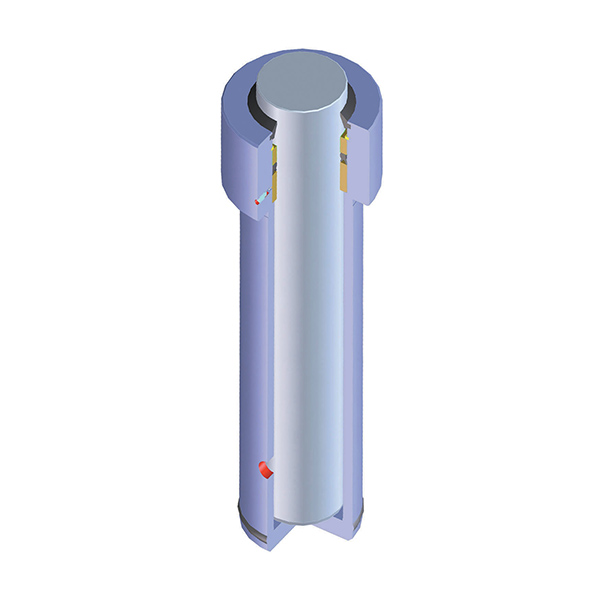

- Hydraulic cylinder castings are made with high grade steel which are robotically welded

- The rams are manufactured with chrome-plated double precision ground steel.

- Self-lubricating guides diagonally placed, for flatness control

- Rack and pinion system assures constant parallelism of the moving platen during closing and opening

- “TS 400” Touch Screen interface to control all press functions & parameters

- Graphic display of suggested positioning of panels into the press

- Memory for 200 working program which control the pressing time, pressure, piston exclusion and more

- Possibility to automatically exclude cylinders

- Automatic pressure commutation for the panel dimensions

- Fault diagnostic system

- Electronic Flatness Control (EFC) with sensors

- Two-hand timed press closure push-button switches

- Perimeter e-stop safety cable and switch

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Dowel construction. Fast, accurate, durable.

Machinery SolutionsWhen one is considering the many methods of case good assembly, a number of factors are considered. The durability of the joint would be one main consideration. Speed of manufacturing and assembly would be another critical point. And last but not least are accuracy/tolerance.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.