Dowel construction. Fast, accurate, durable.

When one is considering the many methods of case good assembly, a number of factors are considered. The durability of the joint would be one main consideration. Speed of manufacturing and assembly would be another critical point. And last but not least are accuracy/tolerance.

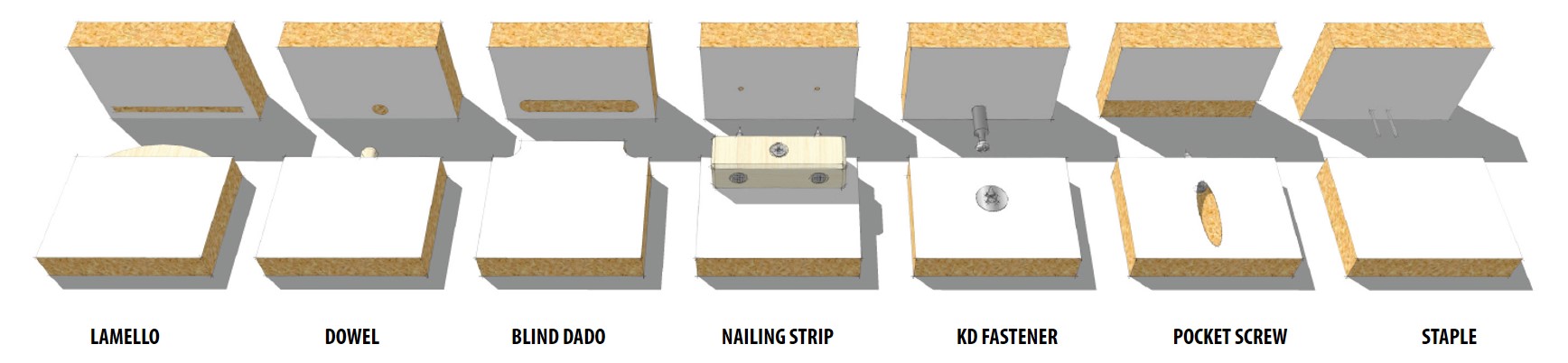

There are several popular methods to assemble case goods in cabinet case good production, with the most popular being dowel, dado, butt joint, pocket screw, screw and nails, biscuits.

When considering your preferred construction method, you need to factor in what is right for your operation. If using a CNC router, you have the option of producing most of the popular joints. If you are equally concerned with speed, accuracy, and durability, you should strongly investigate dowel construction.

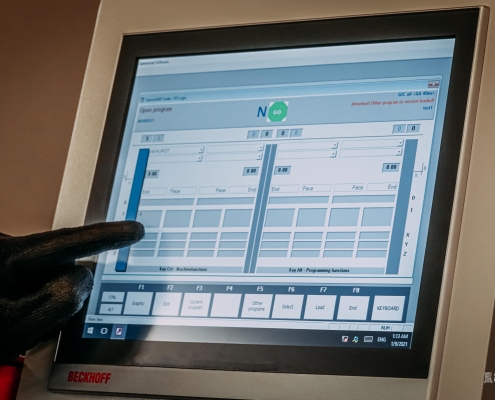

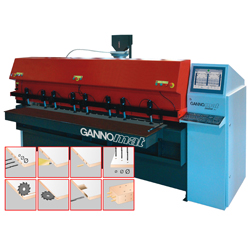

To take advantage of the speed of dowel construction, you need to invest in the right tools. Typically you will be cutting parts on a nested based router or beam panel saw. After the parts are cut & drilled vertically, you will then take the fixed shelves and stretcher rails to a horizontal drilling machine or drilling and dowel inserting machine. From here, you then go to the assembly stage, ideally using a case clamp. Simply insert into the holes on the cables glue by using an electronically controlled glue applicator like the Gannomat Injecta or a fully automatic dowel drilling and inserting machine like the Gannomat Index Logic. By inserting the correct glue amount you ensure a strong bond with no cleaning. Then into a case clamp, like our Gannomat Concept series, for final assembly. Clamping time will depend on the glue, but it will typically remain in the clamp for 2 to 5 minutes or as quick as you can assemble the next cabinet to insert in the clamp.

The assembly is very fast in comparison to other construction methods. Also, as the dowels are hidden, there is no need to cover up nails or screws on exposed ends. If you are nesting the cabinets, a typical cycle time would be around 6 minutes per sheet with dowel construction and up to 10 minutes in comparison to blind dado. You do have the extra step of taking parts to the horizontal boring machine, but this time is made up for the processing and assembly stages. Dowel construction can be used to assemble drawers as well. By manufacturing the drawers yourself, adding a vertical drill to your CNC doweling machine is also an option Gannomat offers.

Gannomats CNC dowel inserters can also be equipped with a horizontal saw for blind panel groove as well with Pocket-Screw-Units. When the CNC is routing and vertical drilling, with Gannomat Index Logic, the operator can work at the CNC dowel inserting machine. The time for horizontal drill glue dowel can be calculated with zero time consumption.

One thing to consider when constructing a cabinet is how easily and accurately the edges line up. This is critical for the cabinet’s overall look, and especially if you intend to put crown moulding on the upper cabinets. Any misaligned pieces will certainly show a gap. With dowel construction, you can accurately drill the components vertically on a CNC machine.

The horizontal holes will have a fixed measurement from the edge to the center of the hole and are easily drilled at the CNC dowel inserter. This operation is very accurate. It is important to use the same surface for reference to ensure accuracy. When you go to the assembly stage, the piece will line up perfectly on the top and the front. This will eliminate any gaps and the result will be a very tight cabinet.

Producing and assembly dowel case goods are also very simple and do not require skilled craftsmen. A CNC router and CNC dowel inserter ensure accuracy and repeatability. When clamping the cabinet in a case clamp, you are ensuring that it is perfectly square. When installing cabinets side by side, they will line up extremely accurately without gaps.

A goal of a cabinet maker should be to build a cabinet that will last. We use our kitchens and cabinets every day and store heavy items on the shelves, so they need to stand up to this daily abuse. When considering dowel construction, one should understand how durable this joint actually is. Our Gannomat dowel inserters are one of the only machines on the market capable of properly inserting glue (rather than inserting water to pre-glued dowels). Dowels with glue are 33% stronger than using pre-glued dowels.

A study performed by FP Innovations investigated the joint strength of eight different construction methods. The dowel excelled at the shear, tensile, and parallel strength tests. Another independent study performed by Steve Morris, as found on Canadian Woodworking, explains that a dowel joint tested failed at 240 lbs pressure, where a biscuit joint failed at 100 lbs.

If you would like to learn more about our Gannomat dowel and cabinet construction solutions, from CNC dowel inserter, case clamp, glue applicator to hinge inserters, to speed up your operation, Akhurst Machinery is here to support you. Building Trust. Creating together.