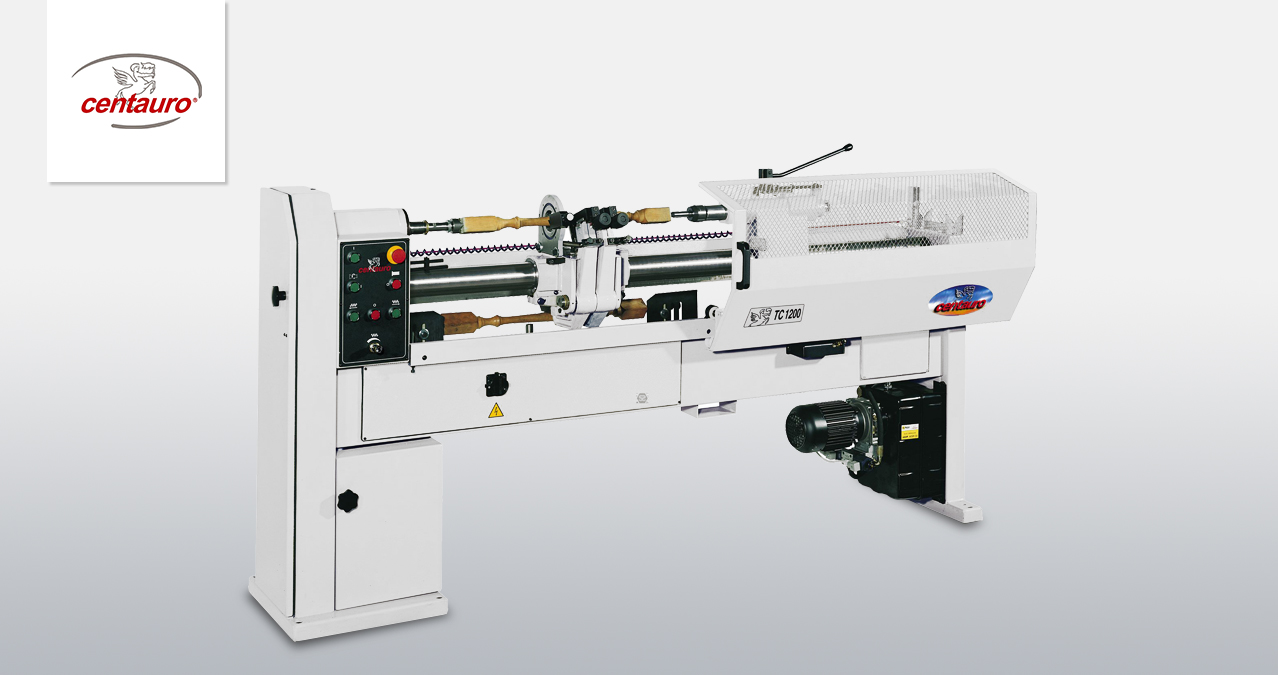

Copy lathe for the production of stair spindles, table & chair legs, and more.

The Centauro TC1200 Mechanical Copy Lathe is a turning lathe suitable for the production in small and medium batches of stair spindles, table and chair legs and furniture components in general. The double cantilever turning assembly works with 2 independent gouges in conjunction with the traveling steady rest. This system allows the perfect reproduction of even the smallest diameter pieces. The variable speed hydraulic saddle movement ensures the highest quality of finishing.

Why Centauro TC1200 Mechanical Copy Lathe?

- Ideal for small and medium production

- 1200 mm maximum distance between centers

- Ability to perfectly reproduce even the smallest diameter pieces

- Highest quality of finishing

- Rapid workpiece centering device

- Tool support rest for occasional hand turning finishes

STANDARD EQUIPMENT

- Self-braking motor (for CE version only)

- Drive centre with 2 interchangeable heads 28 and 45 mm Ø

- Tailstock revolving centre 12 mm Ø

- Traveling steady rest max. Ø 90 mm (square 65 x 65 mm) with reduction bush

- 2 vertical gouges, radius 1,2 mm and 1 precutting tool

- Workpieces centring device

- Tool support rest for hand turning

- 2 extraction ducts 100 mm dia.

- Motor protection switch

- Emergency push-button

- Front sliding guard

- Service tools

- Abrasive stone for cutting edge dressing.

SPECIFICATIONS

OPTIONS

Pre-milling for Edgebanders.

Machinery SolutionsMore often today you are finding features on smaller edge banders that initially were exclusive to larger, higher production machines. One of those features is pre-milling. Pre-milling consists of two counter-rotating cutterheads which are designed to mill the edge of the panel prior to applying the edge banding material.

Proper edgebander maintenance.

Machinery SolutionsEdgebanders are one of the more complex machines in operation in most cabinet and millwork shops. The maintenance however is imperative to the performance and reliability of the machine. Without it you can experience a poor edge quality which will result in hand finishing and defects and worst of all significant down time and expense […]