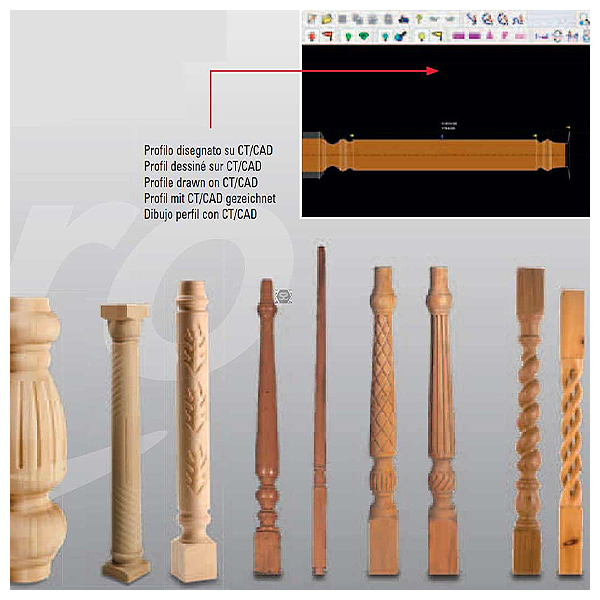

Flexible CNC Lathe for production of custom and repeat turnings for stair railings, chair & table legs, furniture, and more

The Centauro T-Star CNC Semi-Automatic Lathe is a competitively priced, semi-automatic copy lathe with CNC control suitable for producing a range of turned components.

The CNC control means that no sample or template is needed making it very simple and quick to set up and so ideal for short production runs and one of’s. As standard the machine has a 15″ color touch screen and OSAI controller featuring CT CAD software to easily create the profile to be turned.

There is also the possibility to install the CT CAD software on remote PC or laptop and transfer the data to the machine controller via USB stick. Features of the software include the possibility to program up to 10 working passes, multi cuts on specific parts of the turning or return cuts. As the X and Y axis (traverse speed / depth of cut) are NC controlled it is possible to achieve excellent quality and definition of the turned component in all types of materials. The machine is also equipped with 2 x mechanically operated dowel / tenon knives.

Why Centauro T-Star CNC Semi-Automatic Lathe?

- Ideal for small and medium production

- Saddle traverse on linear guides with recirculating balls

- Vertical back knife for dowel cutting, etc.

- OSAI controller for total programming and profiles machining

- No sample or template needed; simple and quick set up

- Brushless motors for X-Y axis.

- X axis movement with rack-pinion system,

- while Y axis is via ball-circulation screw.

- CT/CAD for:

- drawing profiles even on machine board

- programming of milling operations (option)

- import of ISO files (option)

- decorative carvings (option)

- OSAI controller.

- PC Touch screen 15”.

- Turning with a single cobalt gouge, radius 1,2 mm.

- Capable of programming up to 10 working passes.

- Capable of making partial working passes and re-machining.

- Capable of hand-turning (see options on pricelist).

- Multifunction movable push button panel.

- Mechanical workpiece centering device.

- Electric spindle brake.

- Traveling steady 110 mm dia.

- Multifunction movable push button panel.

- Mechanical workpiece centering device.

- Electric spindle brake.

- Traveling steady 110 mm dia.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.