Precise NC Machining Centre for Door Hardware, Window Frames, Shutters, Stair Components and more.

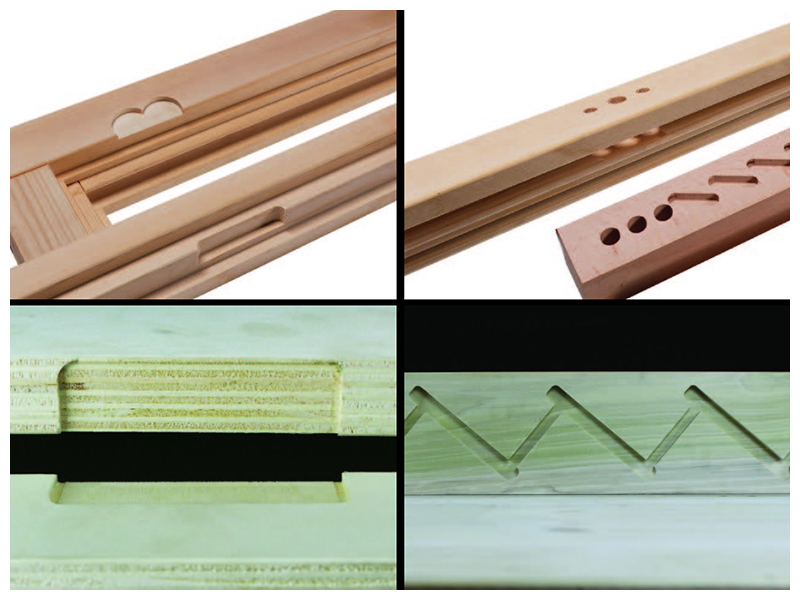

The Centauro ALFA NC Machining Centre is a versatile and flexible NC controlled machining centre suitable for a variety of door machining operations including hinge recessing, lock slots, handle holes, key slots, and euro grooves and more. In addition, it can be configured for machining window frames, shutters, components of stairs and furniture in general. With its simple graphic touch screen interface & built-in macro programs programming is done with ease.

As standard the machine can be equipped with one milling head that automatically moves for either vertical or horizontal machining. It also has interpolation of the axis. Optional additional machining operations include producing a square corner hinge plate recess or lock face recess by means of the additional milling unit. The operator simply selects in the program if they want a radius or square corner, and the machine does the rest. In addition, the same milling head can be used to make the small pilot hole for hinge screws etc. There is also the possibility to produce a square end tenon, round end tenon or dovetail / dovetail slot when the special front table is fitted. Lastly on request the machine can be configured to import ISO files from external design software to enable detailed engraving of items such as name plates etc.

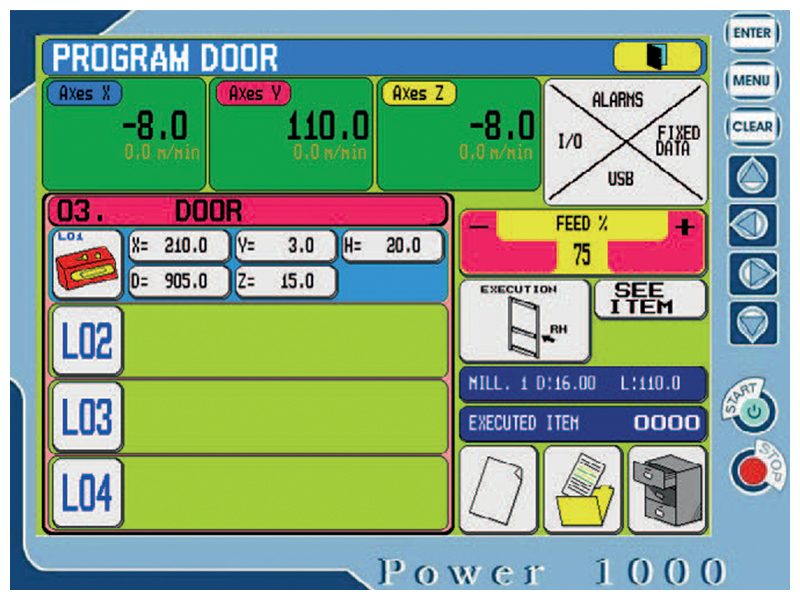

Developed with the latest technical solutions, the machine is fully electronically organized with brushless motors, ball recirculating screws and with ball recirculating linear guides. Directly from the Electronic Control “touch screen”, the operator can realize or import (via USB port) work programs in a simple and intuitive way using pre-installed macros to perform accurate milling. The change of working process is extremely quick. A simple and guided procedure allows quick calibration of the axes to ensure maximum precision machining. Each specific tool, with all its features, is stored on electronic control, to be used in the most various processes.

Why Centauro ALFA NC Machining Centre?

- Quick and precise machining operations increases productivity and eliminates costly defects or rework.

- Big milling capacity of up to 2800 mm in length at either 0° or 90°. The machine is also sturdy and very compact.

- Touch-screen controller with pre-installed macros for user-friendly programming.

- Graphic touch-screen controller with USB port is especially user-friendly and makes switching between programs very quick and easy.

- Possibility of automatic vertical and horizontal millings on beams or windows and door frames.

- The programmable milling unit is extremely flexible and can perform several machining operations including jalousie window slots and hinge recessing.

ELECTRONIC CONTROL

- 15” color touch screen control

- Customized Centauro operating system

- Pre-set macro programming for increased throughput

- Optional remote programming and capability to bring programs to the machine by USB

STANDARD ROUTER MOTOR

- 3 kW router spindle for drilling & milling operations on doors and France on a horizontal or vertical plate

- Programmable router speed from 0-18000 RPM

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.

Achieving optimum performance from your edgebander.

Service and SupportEdgebanders tend to be one of the more complex machines to operate in a woodworking shop, and their performance has a vital impact on the quality of your finished product. Proper machine setup, maintenance, and cleaning play a major role in achieving the best edgebanding results. Below are some basic tips that can greatly reduce the downtime you experience on your edgebander and keep it producing quality components.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.