Accomplish your tasks without worrying about the performance of your sander.

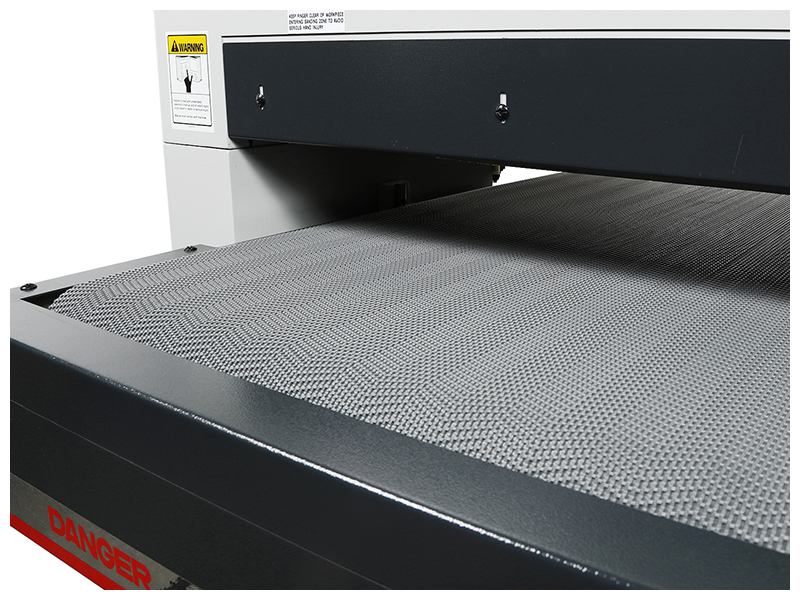

The Cantek S432 43″ Two Head Wide Belt Sander is perfect for any small to mid-sized shop looking to achieve outstanding results. Its robust construction is the best in its class and provides superior sanding results. The flexibility with quick-change abrasive belts allows for more applications in a shorter time frame, helping to assist and meet deadlines. In addition, the S432 has a relatively small footprint providing greater access for smaller shops to accomplish bigger results. Equipped with motorized thickness adjustment with digital input control with settings to 0.001″ / 0.01mm for precise table setting without compromise.

Why Cantek S432 43″ Widebelt Sander?

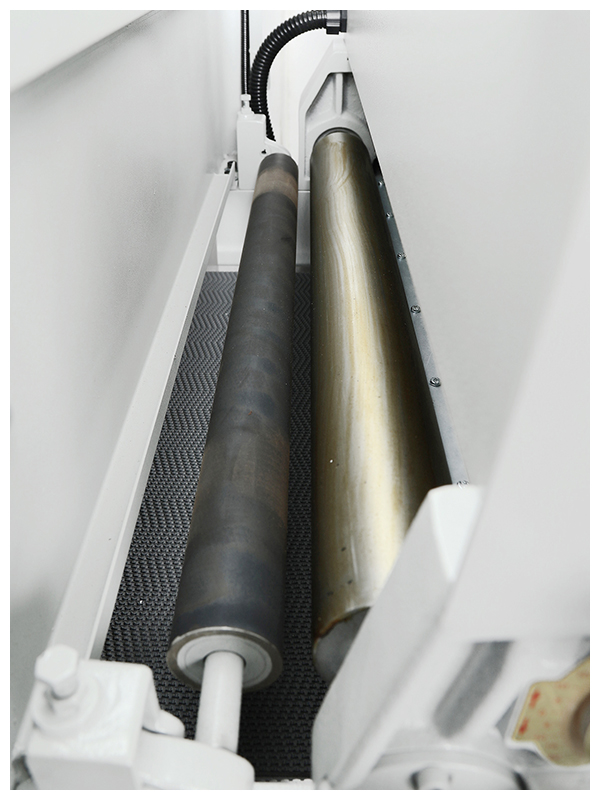

- Dual sanding heads increase efficiency by reducing the number of passes.

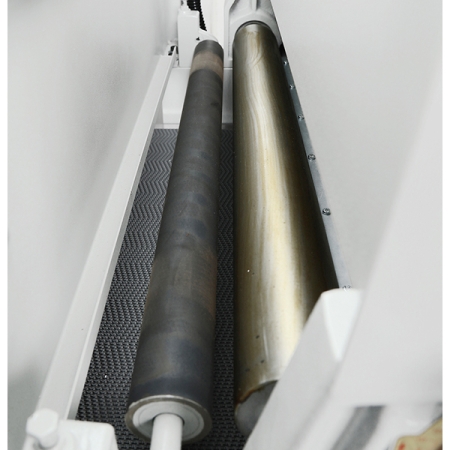

- Rubber contact drum for calibration sanding.

- Combination sanding unit with 5″ rubber contact drum and 2″ wide adjustable sanding platen for a wide range of sanding applications.

- Adjustable platen produces superior sanding results with finer sandpaper grits.

- Accurate digital thickness control with both Inch & Metric settings allows the operator to key in the desired thickness, and table will automatically move into position.

- Small footprint.

- Two sanding heads:

- First Head: Rubber contact drum with 7″ diameter drum.

- Second Head: Combination head with 5″ diameter drum and 2″ wide platen.

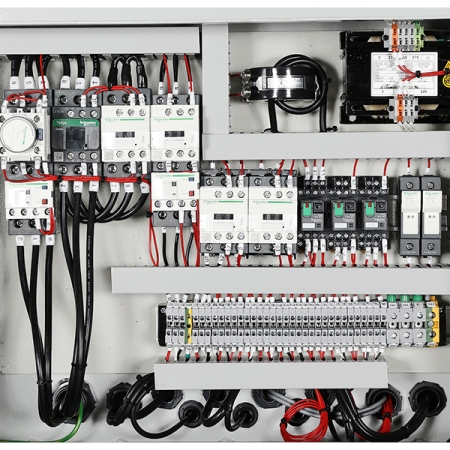

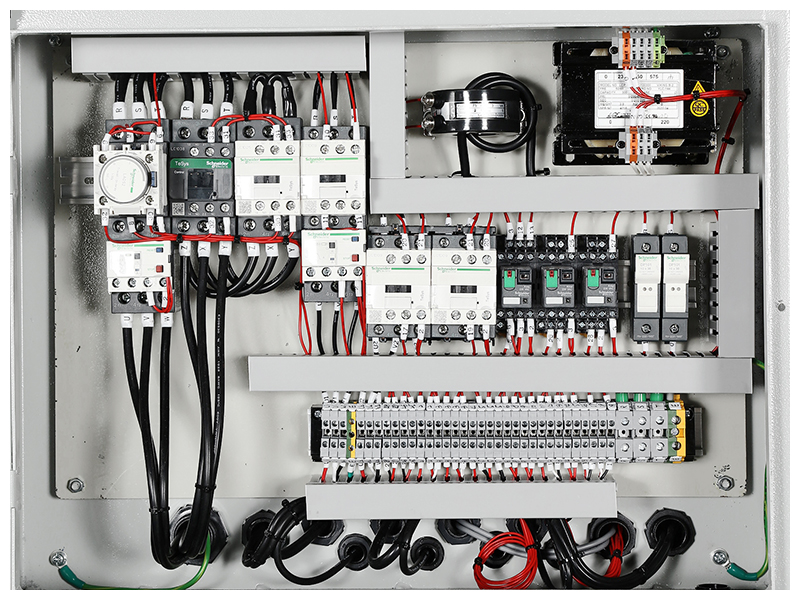

- Electronic belt tracking for optimum belt life and sanding results.

- Ammeter for load monitoring to ensure the proper amount of material is removed according to the selected grit.

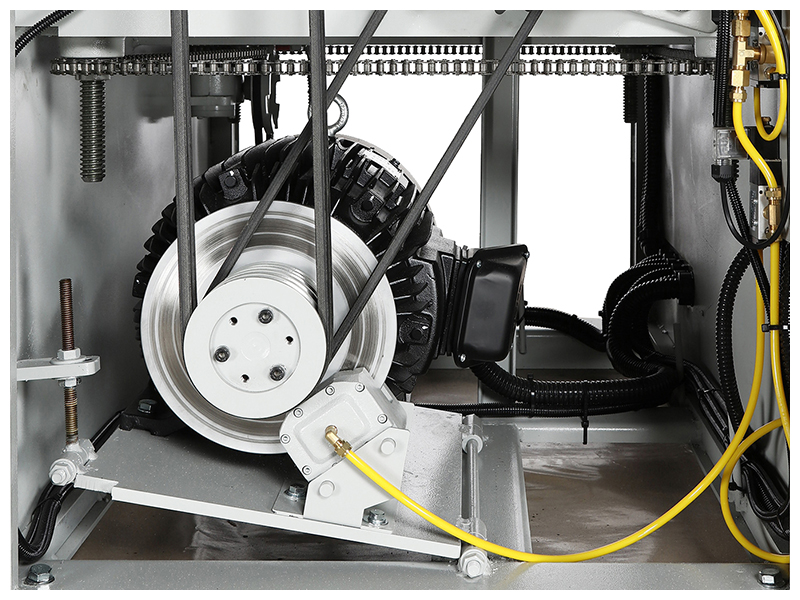

- Disc brake on the main motor allows for faster belt changes.

- Pneumatic belt tensioning with quick release outboard support to facilitate fast belt changes.

- Table raising jackscrews.

- Interlocks are located on all access doors.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.

Poor finishing results? Stay alert for the most common widebelt sanding issues.

Service and SupportWidebelt sanding is a critical stage in wood preparation before and during the finishing process. Often poor sanding results do not show up until it is too late and you have finished the material. Knowing what issues to look for and how to remedy them in advance will save you both time and money by eliminating costly rework and defects.

Regular maintenance can save you money and time on your wide belt sander.

Service and SupportProviding regular maintenance on your wide belt sander can help mitigate small problems from turning into larger ones. These issues can often cause a halt to production and lead to costly delays.