Stop losing untapped revenue by turning your wood waste into valuable material.

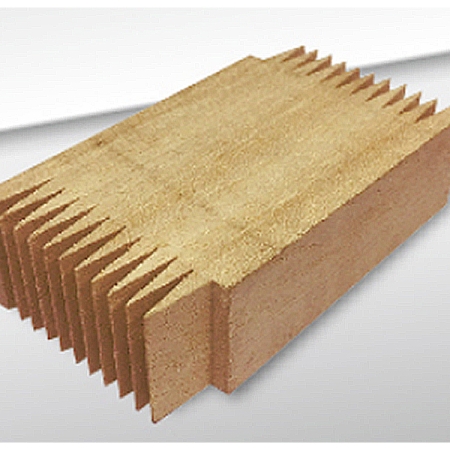

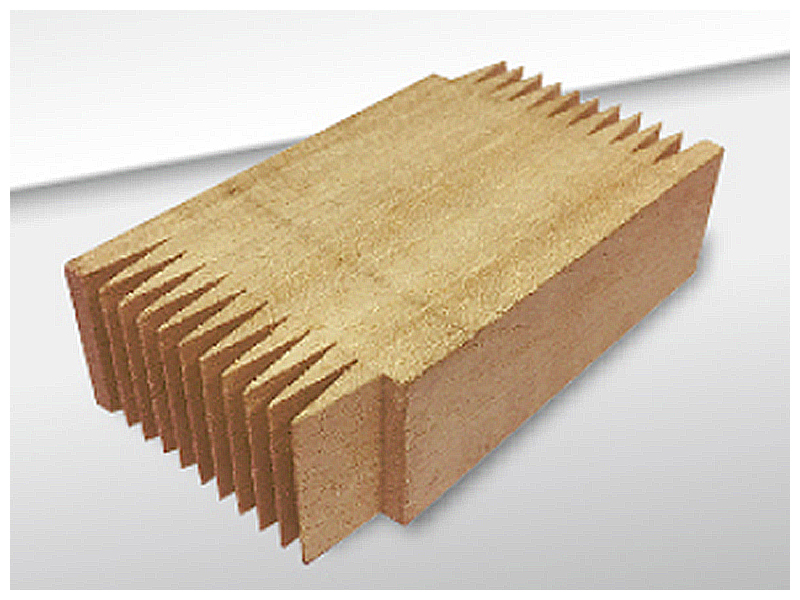

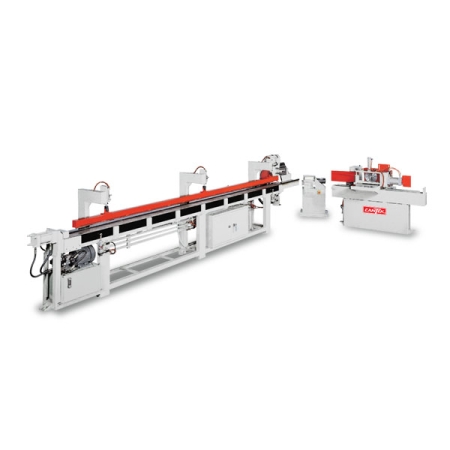

The Cantek FL24 Semi-Automatic Finger Jointer represents a state-of-the-art finger jointing production line, meticulously crafted to transform extra short wood waste into valuable materials, all the while upholding an exceptional balance between performance and cost-effectiveness. Its compact design with multiple automatic features and options makes it an ideal solution for a small sized finger jointing operation. By utilizing a solitary shaper setup, this system delivers extraordinary value in performance and affordability, positioning it as an enduring revolutionary force within the woodworking sector.

Why Cantek FL24 Semi-Automatic Finger Jointer?

- Semi-automatic finger jointer with a small footprint

- Excellent performance-to-cost ratio

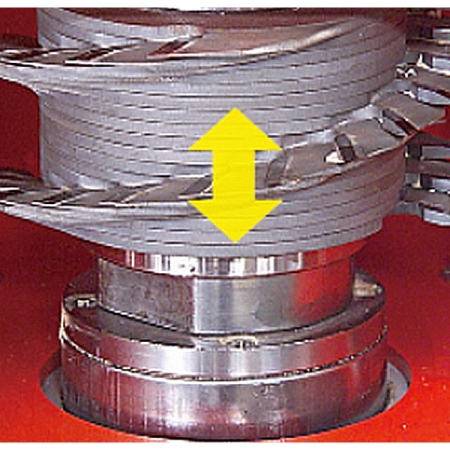

- Right/left finger shaper scores, profiles, and glues both right and left joints in a single machine

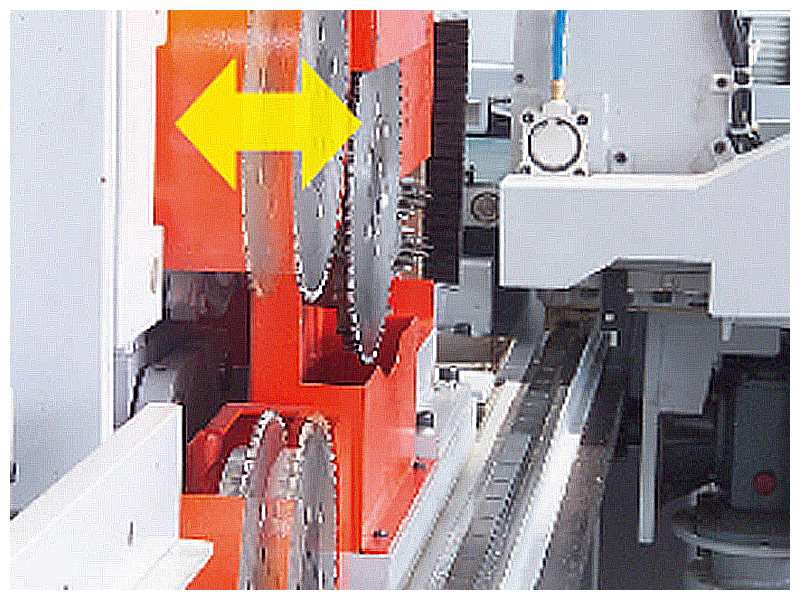

- Workpieces automatically travel between profiling & gluing stations

- Production speed: 2~3 cycles/min

- Length of cut is calculated by an encoder and set on a touch screen for increased accuracy with a finished board tolerance of 0 to 0.08” (0 to 2mm)

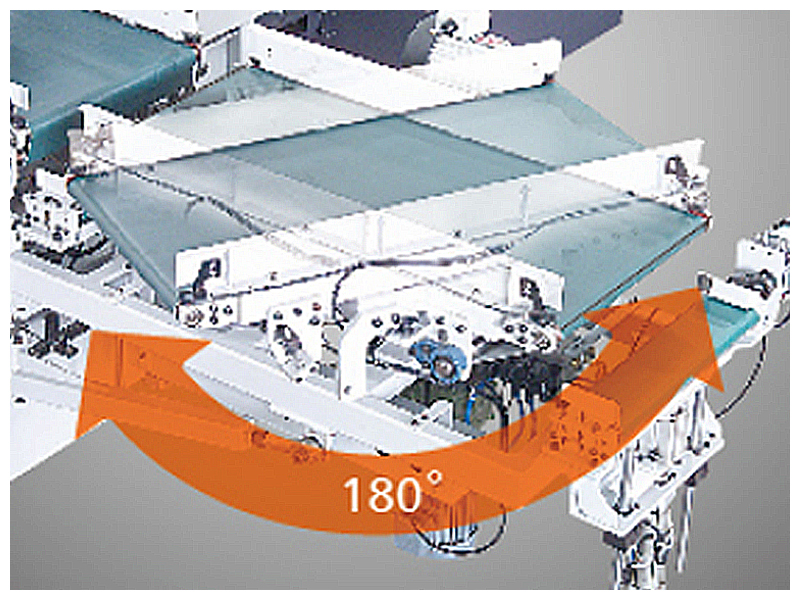

- Manual rotary table design turns pieces to allow processing of both ends on a single shaper system – optional automatic rotary table available

- Optional automatic adjustment of the scoring blades and shaper section for left & right profiles

- Presses available in various lengths to suit your production needs

- Applicable for machining extra short wood waste of 4” (100mm)

- Only two operators required for max production

- Hopper loader mounted for workpieces to automatically feed into the assembly press comes standard with the FL-24

- As standard we use PVAc glue, but we have optional gluing systems for PUR, MUF, EPI, etc. available upon request

- Synchronized jointing and length cutting is performed in a 2-step process within the F-A05 or A07 single stage automatic infeed finger assembler