High-speed nesting line for maximum throughput.

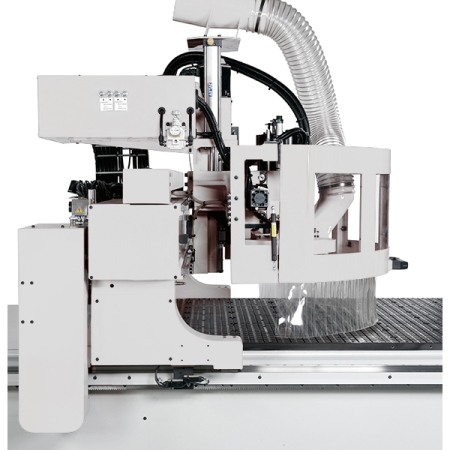

The Anderson Selexx Full Line CNC Router is a fully integrated automatic nesting CNC router line that greatly reduces cycle times by shortening the loading and unloading operations. The full line system allows for automated part labelling, automatic loading and offloading capabilities to the already full-featured Anderson Selexx Series CNC Router. Available as both a complete line or in customized selections, the Selexx Full Line CNC Router can be configured to meet your workflow demands in a fully functional package. These features are designed to increase production by minimizing the loading and unloading cycle time and improved part identification resulting in faster assembly times.

Why Anderson Selexx Full Line CNC Router?

- Increase productivity by reducing the loading & unloading operations.

- Optional automatic bar code or part labelling for improved part identification.

- Scissor lift indexing table in combination with the suction loading system allows for the automatic loading of sheets.

- Automatic pusher and dust suction device push parts onto a motorized conveyor while cleaning the spoil board, making it ready to load the next sheet.

- High-speed nesting cell with a single operator.

- Industrial Anderson CNC router with superior cutting speeds for maximum throughput.

The AndersonFully Automatic CNC Router Line Consists of:

- Automatic scissor lift table with three-ton load-bearing capacity for full bundles of panel materials.

- Anderson Selexx CNC Router Models MATE (4×8’), PAL (5×10’), and CHIEF (5×12’) can be equipped with fully automated loading and offloading systems.

- Dust gate to remove any dust and debris from the bottom of the processed sheet.

- Automatic conveyor table for the offloading of finished parts.

- It can also be equipped with automatic part labelling.

- Automatic loading and offloading system.

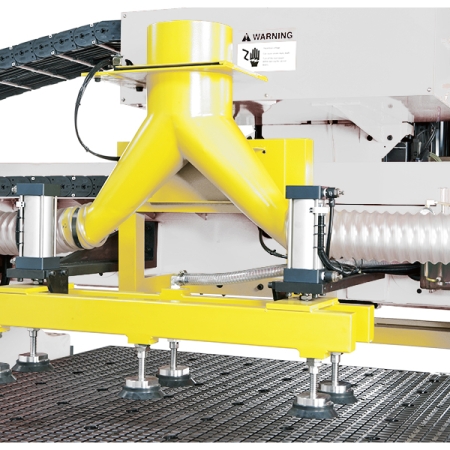

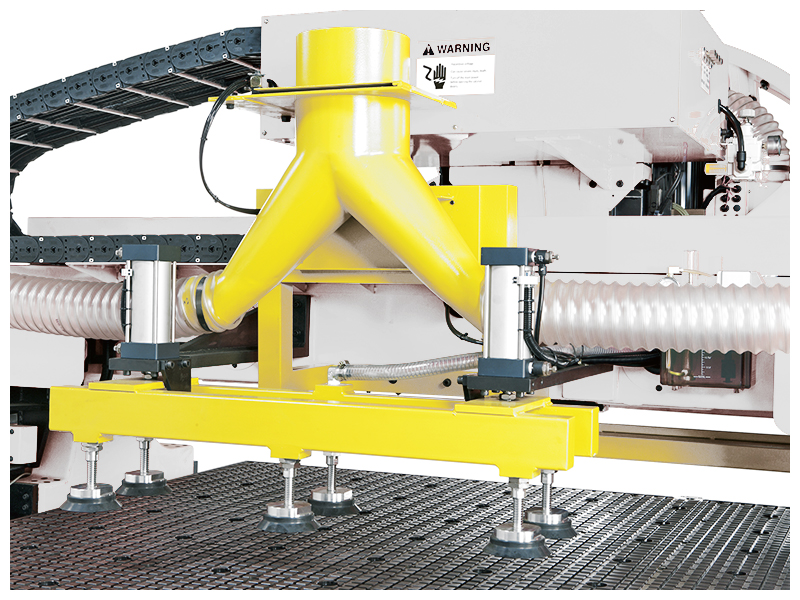

Loading Device

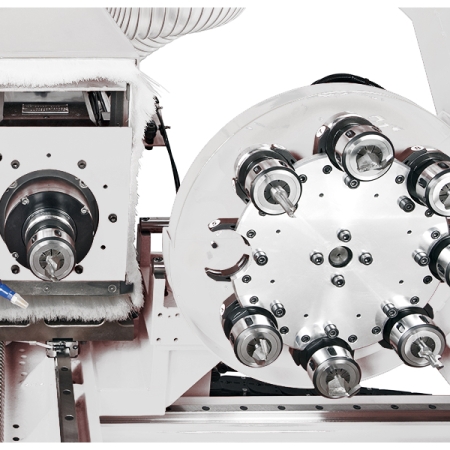

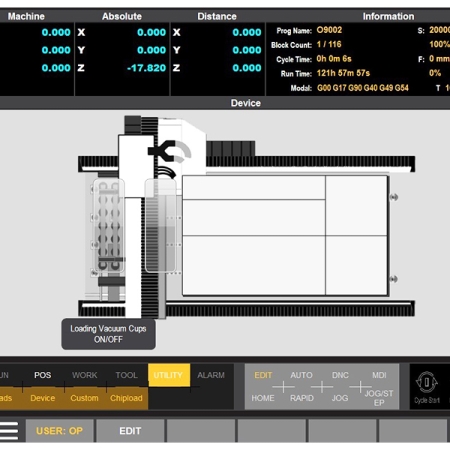

- The Suction Cup Loading Device and Integrated Vacuum Cleaning System is standard on the Anderson Full Line CNC Router.

- The Integrated Vacuum Cleaning System ensures that all dust and debris is removed from the machine table prior to loading the next sheet.

- The six (6) industrial-strength vacuum cups will load and position sheet material onto the tabletop without scratching the surfaces and align them perfectly against the pop-up pins.

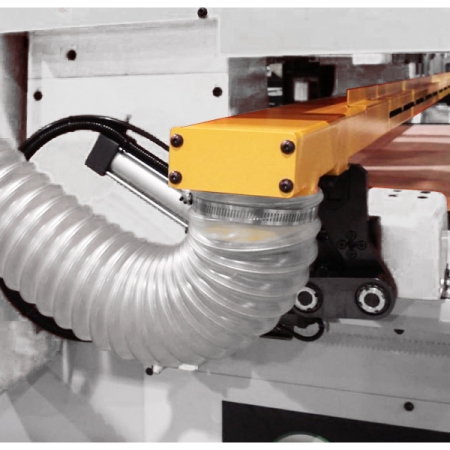

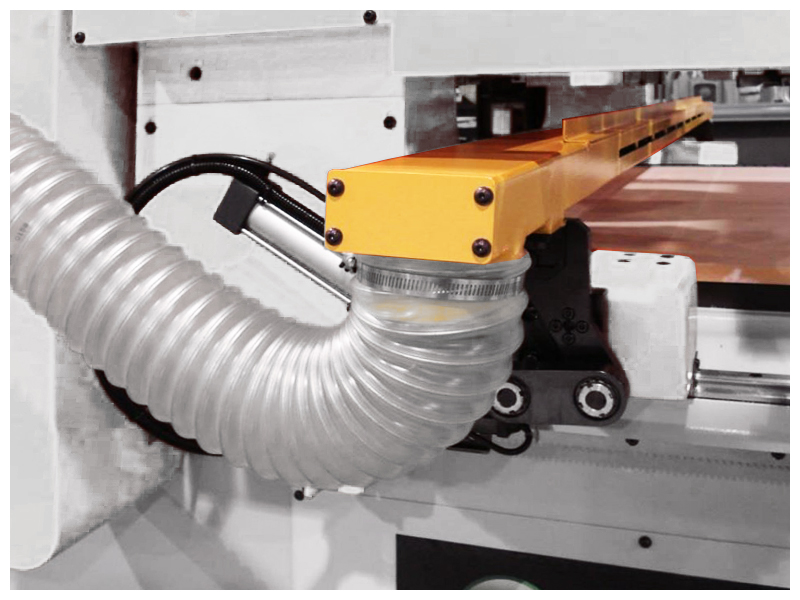

Automatic labelling system

- A popular option to add to the nesting line is the automatic label printer.

- Through its stand-alone software and controller, the label printer effectively reduces the amount of cycle time needed by completing the application of labels before the panel is cut.

*Akhurst Machinery Ltd. is the exclusive distributor for Omnitech Systems / Anderson in Canada. For US inquiries, visit www.andersonamerica.com

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.