Top-quality New Edge Processing Systems from Germany.

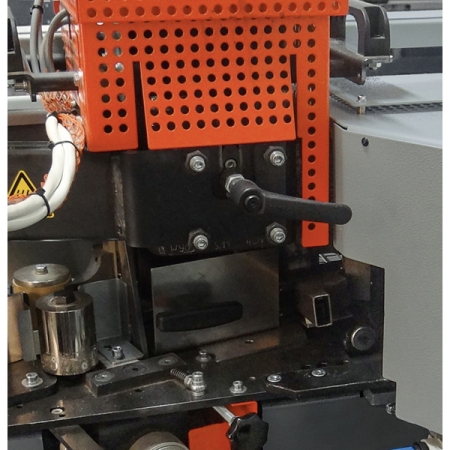

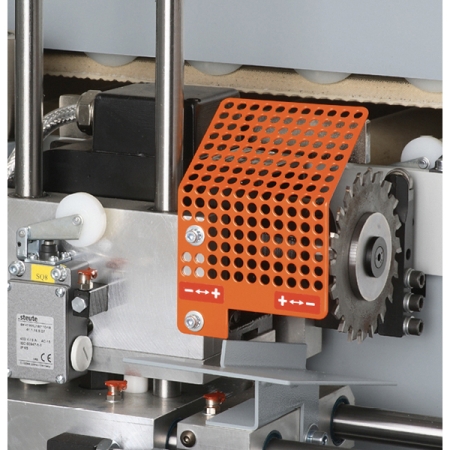

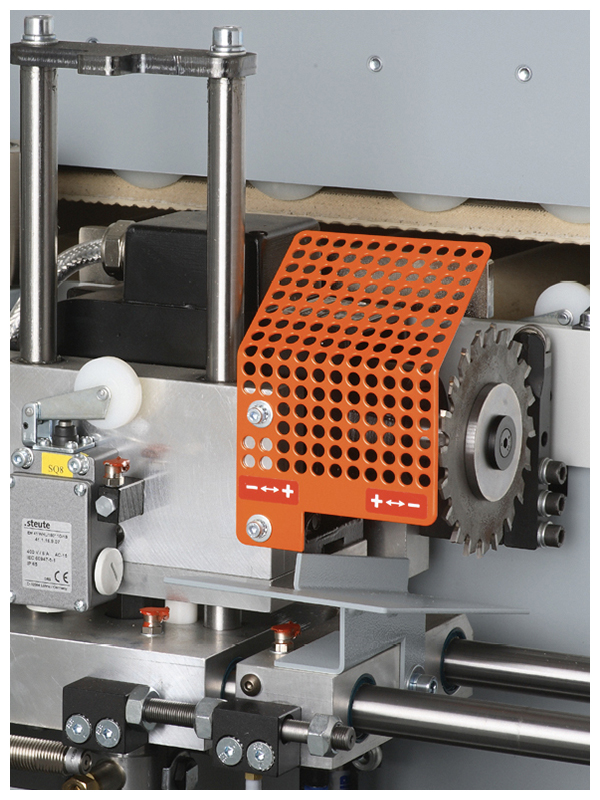

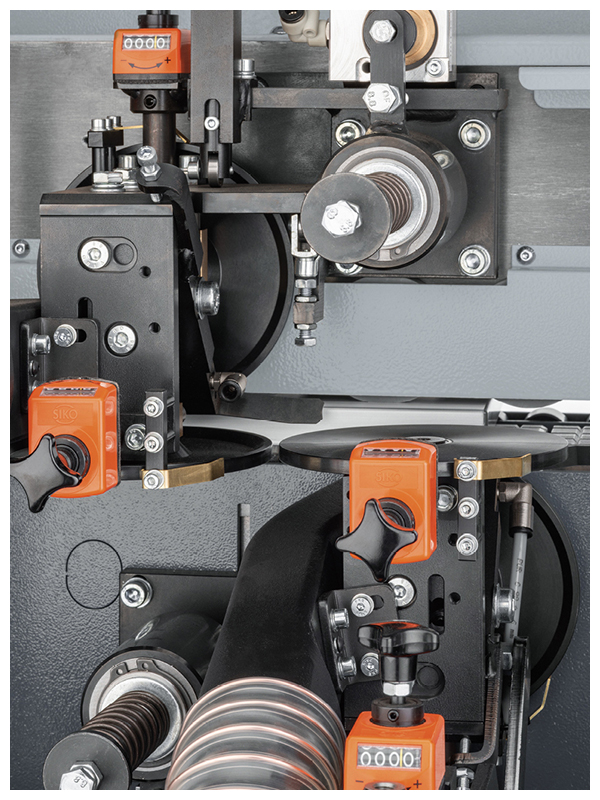

Developed for the highest demands, the Altendorf K36 NEXT Edgebander represents absolute reliability and productivity in daily use. The option of fitting the machine with a step cutter and a multi-radius profile scraper raises Altendorf to a new benchmark in the world of perfect edge finishing with the most diverse edge thicknesses. This Altendorf highlight offers unheard of options.

At approx 1700 kgs, the K36 NEXT is purpose-built for industrial levels of edge banding day and night. This particular Hebrock machine has all the power capability you might need with about 14 kW delivering a rapid feed rate of up to 15 m/min. Easy to service and maintain, the K36 NEXT has a visual display for workpiece sequencing that comes as standard. Optional features include a grooving saw unit and a useful top and bottom trimming system that allows users to double up their processes. Of the three machines in the K range, the K36 NEXT is the middle-sized option, with an overall length of 5540 mm.

Altendorf edgebanders have been developed especially for the requirements of the modern workshop. Altendorf edgebanders impress more and more owner-run workshop operations with mature, proven and perfected technology, from precise edge finishing through to complete machining and with easy to operate control elements, such as touch screen controls. Optional specification elements can be added according to the individual requirements. The K series represents edging technology at the highest possible level. All machines are based on an extremely torsion-resistant housing design. The tried, tested and proven machines impress with their top quality finishing and solid performance. Every Altendorf edgebander is 100% Made in Germany.

Why Altendorf K36 NEXT Edgebander?

- Purpose-built for industrial levels of edgebanding day and night

- The K36 NEXT has all the power capability you might need with about 14 kW delivering a rapid feed rate of up to 15 meters per section

- Easy to service and maintain

- Visual display for workpiece sequencing that comes standard

- PLC control with touch screen 15“

- Pre-milling aggregate

- Trim saw

- Top/bottom trimming

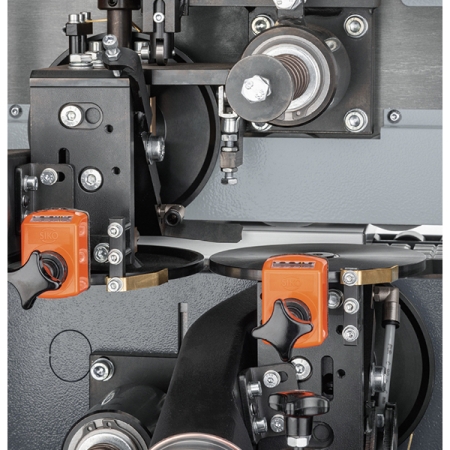

- Corner rounding unit

- Radius profile scraper

- Surface scraper with dual-tracing

- Grooving saw unit

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.