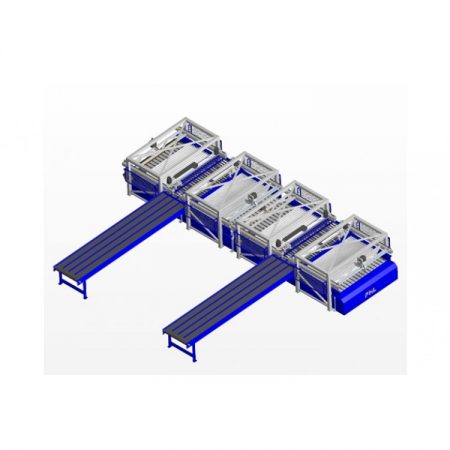

Advanced machine line for the production of Chevron (Hungarian-Point) floor sections.

The Marinus Powermax Chevron machine can be used for endmatching for the production of herringbone and hungarian point (chevron). A unique feature of the Powermax Chevron is the high-tech in and out feed. The combination of feed belts with slides that open and close ensures an optimal product supply. The automatic cross cut saw ensures a constant supply of cut-to-size boards. During processing, the boards are fixed sideways and clamped upwards against an accurate fixed ruler. This results in very high profile and angle accuracy. This method of production is the most suitable for making chevron.

Why Marinus Powermax Chevron Machine?

The Powermax Chevron profiles the head-end of floor boards at precise and fixed lengths. The integrated saw makes sure parquet boards are processed to the correct length and the correct angle for your Chevron floor.

- Very dimensionally stable

- Absolute angel accuracy

- Over 25 years of experience in End matching

- Fully automatic

- Online service, diagnostics and support

- Unique production method

- High operational reliability

- High capacity up to 10 boards per minute

- Absolute angle accuracy

- High profile accuracy

- Unique production method

- Integrated automatic cross cut saw

- CNC controlled positioning clapms

- Driven belt conveyor for waste

- CE Safety and Electrical Standards – UL/CSA Standards

- User-Friendly control panel

- Online remote support management

- Advanced Servo Drive & Control Technology by Lenze

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.