BI-MATIC

Used Challenge 4.5A Edgebander

Machine Information

Features

Especially designed for the application of veneer, PVC, ABS, melamine and solid wood strips from .4mm up to 5mm of thickness.

FEATURES

- Solid Steel Fence: 680mm L x 20mm W x 60mm H

- Heatable from 0° to 90° approx. with a thermometer; with heavy steel support for the panel.

- Teflon Coated Lower Glue Pot

- With quick heating time (Approx. 6 minutes)

- Capacity of 3 Litres

- With granulated glue

- Manual movement of glue pot (via handle) in/out of glue line (Apply or not apply glue on panel edge)

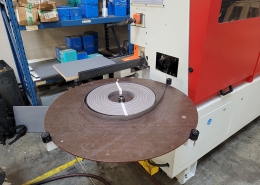

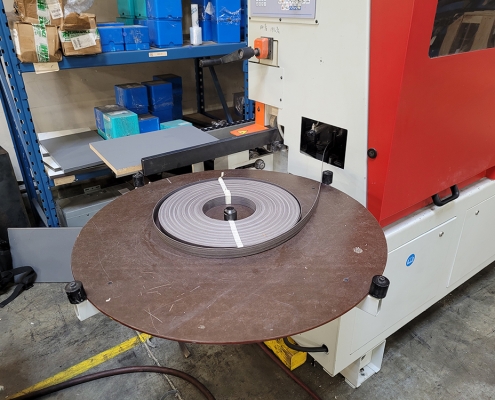

- Coil magazine @ 800mm diameter

- Automatic wood strip magazine for edge thickness from 0.4mm up to 5mm.

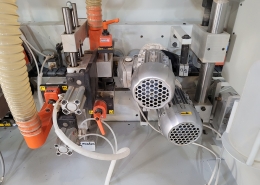

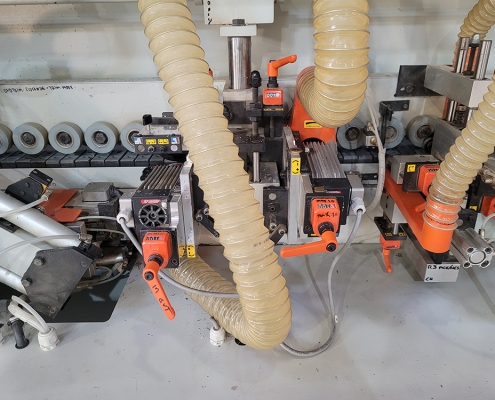

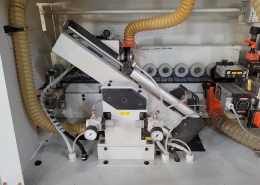

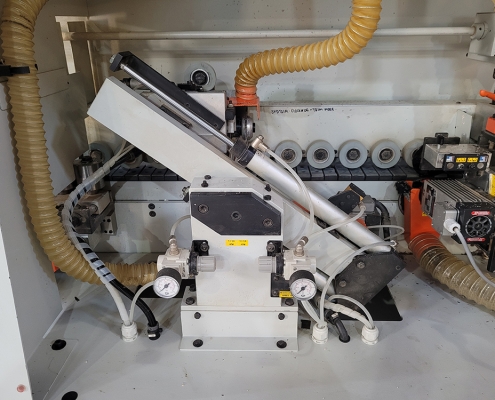

- Vertical shear for cutting ABS and PVC up to 3mm thick and 64mm width, with vertical movement and horizontal copying movement. The function is electro-pneumatic.

- Pressure roller zone composed by nr. 03 rollers. The first pressure roller (100mm Dia.) is steel and motorized. The other 2 idle rollers (60mm Dia.) are with opposing degree tilt for a perfect pressing. This unit is equipped with manual movement with a digital counter.

- Automatic adjustment of the top groups when moving pressure beam up / down.

- Touch Pad Control Panel

- Sets temperature of glue heat requirements

- Sets lower temperature in stand-by mode when machine not in use (glue will not burn)

- Enters values for activation of coil cut-off system, leading/tailing edge cutting for end trim saw

- Displays feed speeds

- Displays number of pieces processed

- Displays error codes

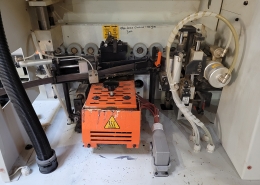

- Line Control Feed System

- A line control system ties the activation of the spiked roller, guillotine, & end trim saws to the computer/encoder.

- The operator can then easily, accurately, and quickly make adjustments through the control panel (no micro switches to adjust)

- Feed on Left / Work stations on Right – When standing at feeding end of machine.

Working Units

Specifications

Machine Details