LEADERMAC

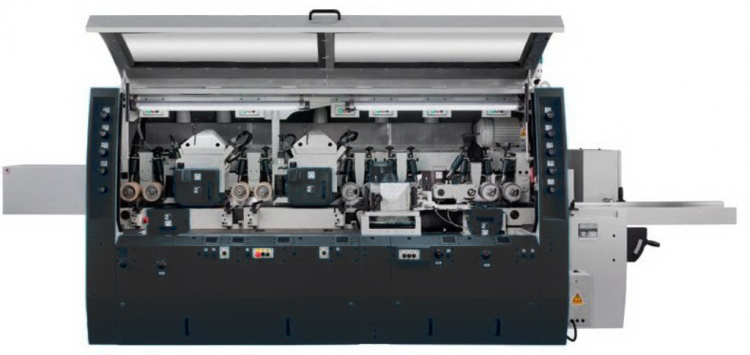

U Power Moulder Series

Machine Information

FEATURES

MAIN FRAME, MACHINE BED & ENCLOSURE

- 1 Piece – Extra Heavy Main Frame. Specially heat treated for maximum stability and minimum vibration

- 78 inch (2 meter) long Adjustable Infeed Table and Fence (each adjustable .4 inch) – other lengths optional

- All Tables and Fences are Hard Chromed approx. .012”-.014” Chrome Thickness

- Lift up sound and safety Enclosure including safety interlocks and good Strobe-Free lighting inside the enclosure

DRIVE INCLUDES

- Maintenance free Full Cardan Shaft Drive to feedworks for balanced drive performance, with individual worm reduction gear box to each feed roll station

- Powered rise and fall to extra heavy feed support beam by 3/4 hp/.55 kw motor.

- Upper support Beam is supported at both the Infeed and Outfeed ends on 2 large columns for best, most rigid upper beam support.

- All feed rolls and pressures move with top beam rise and fall, including safety switches at extreme points.

- 9 Top Driven Feed Roll Assemblies (each equipped with Multiple 2” wide rolls that can be quickly spaced/positioned or removed as desired)

- 3 driven Full width Bed(Bottom) Rolls

- Top infeed rolls before first bottom head with pneumatic rise and fall by switch

- Centrally located Pneumatic Pressure Gauges & Controls for Top Rolls, Chip Breakers and Roll holdover Assembly opposite rear side head on Exterior Column

- All Top Rolls are Pneumatically Tensioned. There are 3 different pressurized groups to the Top Rolls. Infeed, Midfeed & Outfeed Top Rolls. Each group has a pressure gauge and regulator for varying pressure setting. This really helps for the feeding of different materials with different conditions, smoothly and efficiently.

- All Infeed Top Rolls are Hardened, Serrated and Satin Chromed to resist wear and prevent chips and shavings from sticking to them

- Top feed rolls after top head are Polyurethane

- 2 Piece Full width Bottom Driven Infeed Roll

- Intermediate short stock top driven feed roll station with pneumatic pressure for feeding minimum 8”(200mm) length work pieces. It is easily flipped up for rear side head removal.

- Top/Bottom Powered Outfeed Rolls, with bottom full width and plain

- Inch forward and reverse to feed with duplicate control at top head position for fast and easy setting

- Feed roll diameter 5.5” / 140mm

- 5HP VFD Electronic Infinitely Variable Feed Drive 20 – 120 fpm including Inverter Duty

- Feed motor with Brake module and Digital Speed Readout on the Control

SPINDLE ASSEMBLIES, CUTTERHEADS & POSITIONING

- ALL Spindles are 8000 RPM (This way you can increase the machine productivity by 33% over a 6,000 Rpm Moulder)

- 1 13/16” Spindle Diameter – (40mm, 50 mm or 2 1/8”– Optional – No Charge)

- Spindles are manufactured from SCM-440 tool steel (Imported from Mitsubishi-Japan) with special heat treating to HR 55C Hardness fitted with 2 pairs of RHP ABEC 7 Duplex Super high precision high speed Bearings to provide the best in cutting stability with permanent accuracy. Spindle Tolerance is guaranteed to +/-0.002mm / 0.00007” accuracy. They are permanent grease lubed and are sealed and are impervious to dust and water.

- All Spindles have vertical and horizontal adjustment

- Adjustment of all spindles from front – Easy to operate stations

SPECIFICATIONS

| Thickness Material | .4” to 6” |

| Note – to .25” thick and/or to 8” or 10” thick optional | |

| Width Material | .6” to 9” (12” & 13” – optional) |

| Note – You can actually run to 9 1/2” Fin. Width with slighter smaller Near Side head(Please discuss) | |

| Min Length of material | 8” (Butt Fed) |

| Axial adjust. Side Heads | 4”(102 mm) |

Axial adjust. top/btm heads |

.8” (20mm) |

| Net weight | 16,920 lbs. |

Categories: Leadermac Throughfeed Moulders, Moulders