Heavy Duty Steel Beam Processing.

Combining sophisticated Siemens electronics, heavy duty carbide drilling and superior feedback, the Peddinghaus BDL-1250/9D Beam Drill Line is both versatile and efficient. Processing an average of 200 plus tons of structural steel per 40-hour work week, the BDL-1250/9D is the beam drill line solution for large fabricators.

The BDL-1250/9D boasts an impressive 1800 RPM spindle speed with the superior clamping power to accommodate carbide drilling. With today’s modern technologies including micro-mist coolant, spindle specific motors, carbide part marking, Break-Through Detection technology and automatically adjusting roller measurement, we created the industry’s premier beam drill line.

Why Peddinghaus BDL-1250/9D Beam Drill Line?

- Powerful Siemens spindle motors

- 9 spindle drilling

- Optimum guidance of the workpiece through the machine with 4 vertical hold downs and 4 knurled horizontal clamp rollers

- Multi-axis carbide scribing

- Complete positioning feedback

- Minimum quantity lubrication, 97% air, 3% eco-friendly vegetable oil-based lubricant

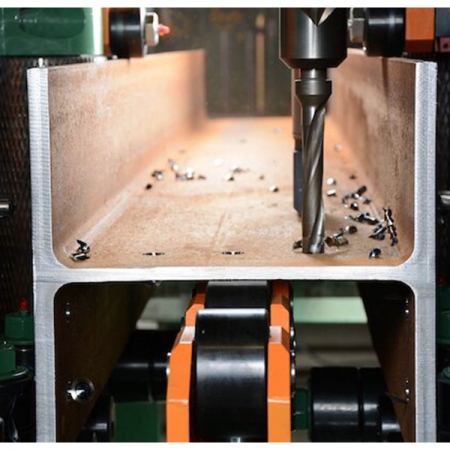

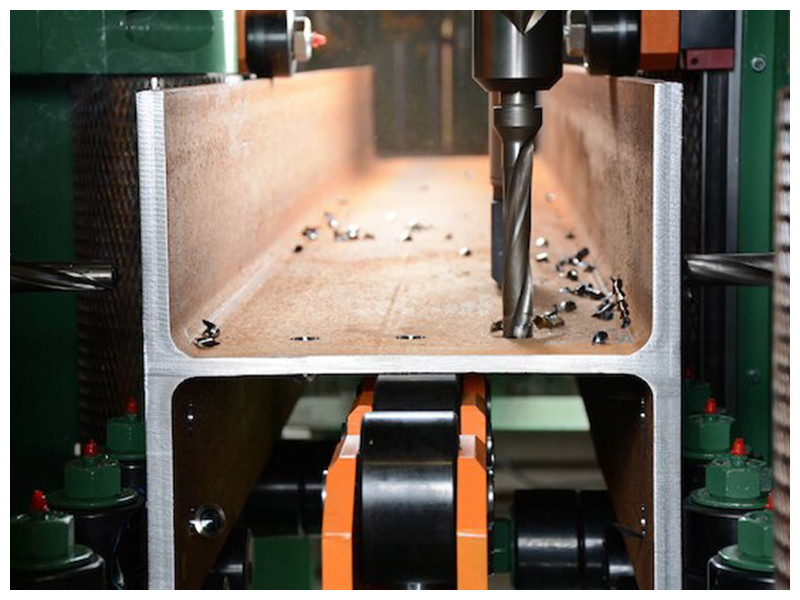

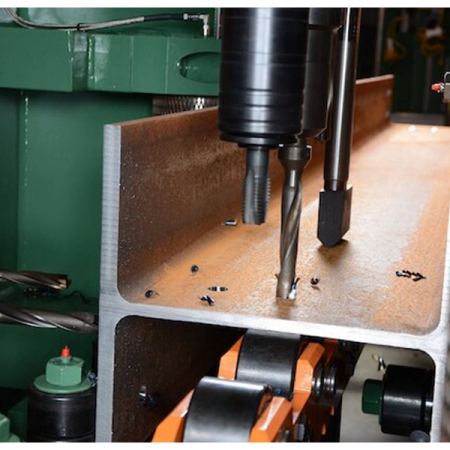

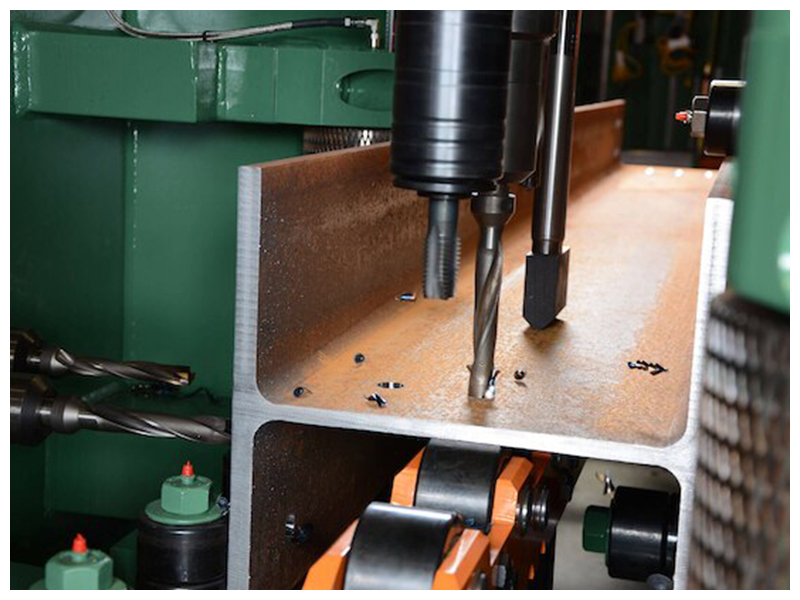

High Speed Carbide Drilling

The drill assemblies of the BDL-1250/9D employ 25 HP (18.5 kW) Siemens servo motors. These spindles boast a speed range of 145-1800 RPM. The exceptional strength of the BDL-1250/9D spindles allow for faster processing times in drilling, tapping, countersinking and scribing using carbide tooling.

Nine Spindles Makes for Constant Operation

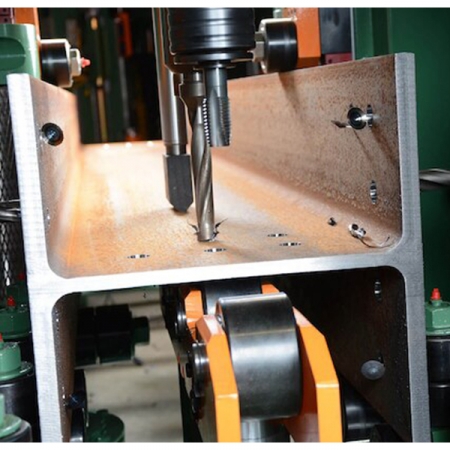

The three drill assemblies on the BDL-1250/9D operate simultaneously or independently of one another using either the same or different drill diameters, speeds and feeds.

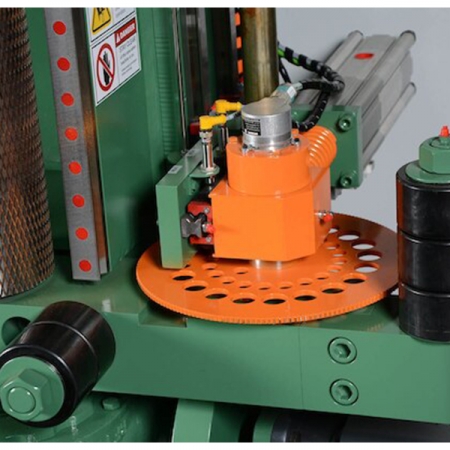

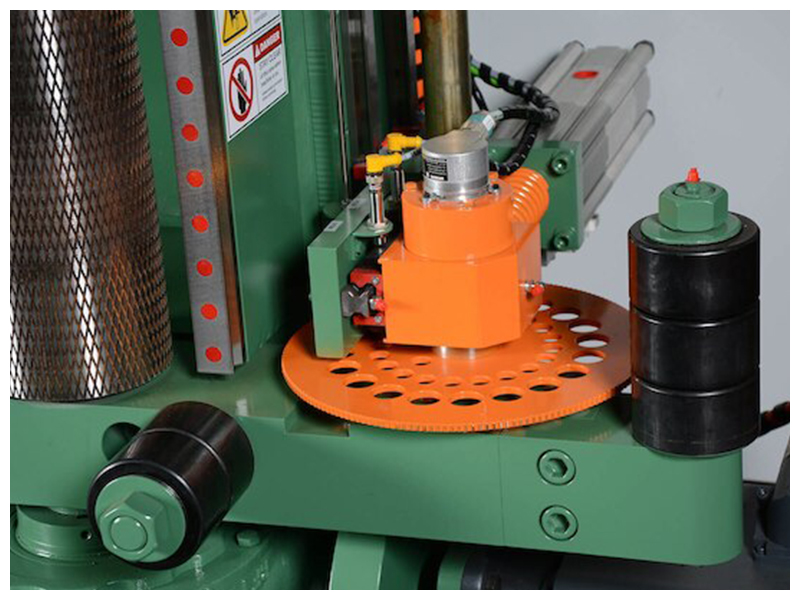

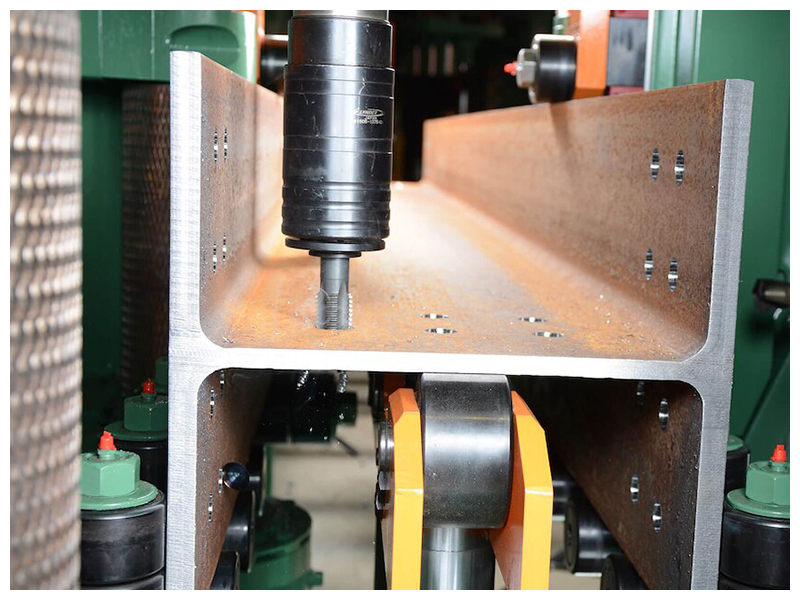

Nonstop Throughput with Roller Feed Measurement

Peddinghaus’ Roller Feed Measurement system exceeds the industry standard for roller measurement technology. Maintaining accurate measurements without any hesitation in production is crucial. Accuracy is not compromised even despite deviations in material.

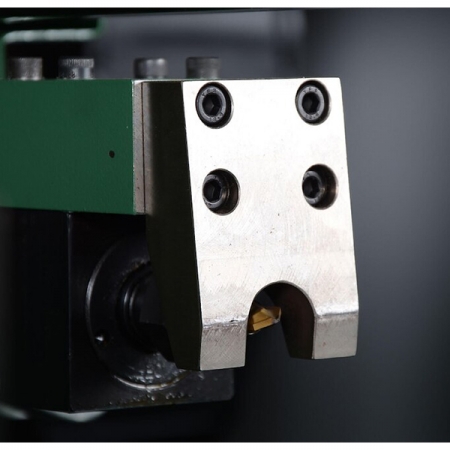

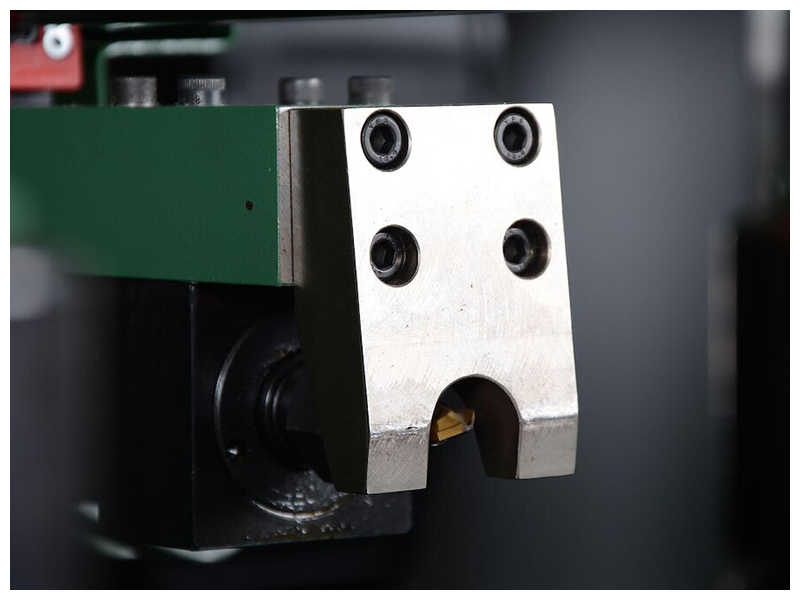

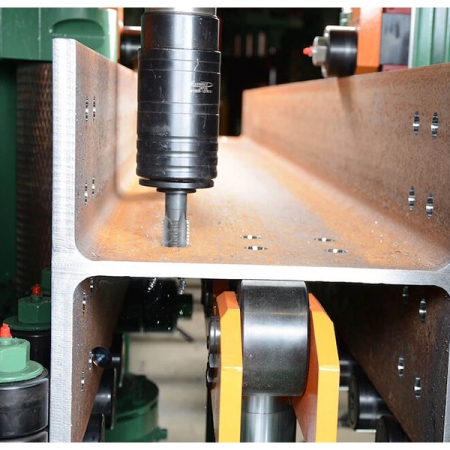

Sturdy Drill Clamping to Eliminate Vibration

The BDL-1250/9D employs a series of support clamps in order to achieve optimum rigidity of the workpiece through the machine. Carbide tool life is best sustained with the least amount of vibration possible.

Break-Through Detection Technology for Faster Drilling

Optional drill break-through detection technology speeds up processing time by minimizing spindle run time. The spindle automatically detects breakthrough of the drilled hole, and rapidly retracts. It then advances to the next hole in the part program. Carbide tooling, along with break-through detection, help the BDL-1250/9D reach record-low processing times with beams, channel, angle, tube and flat bar.

Band Saw Integration

The BDL-1250/9D heavy duty beam drill line with its powerful material handling support, meticulous measurement capabilities and high speed designs are ideal for tandem installations with any of Peddinghaus’ automatic sawing systems.

AccuMeasure Allows Complete Handling Control

Saw measurement options are available via the Peddinghaus AccuMeasure Roller Feed measurement system. The AccuMeasure allows for complete handling versatility, while maintaining a streamlined CNC solution. Splitting apart a drill and a saw allows neither machine to wait for the other, maximizing production.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.