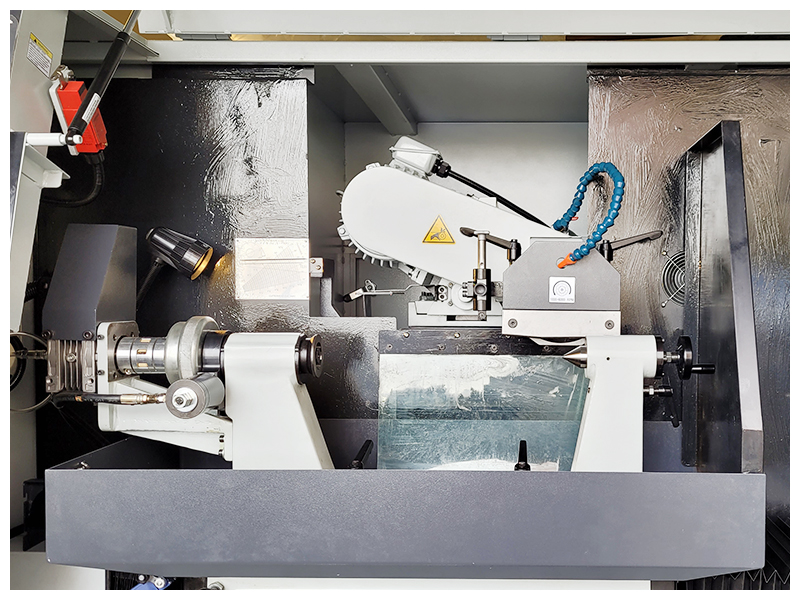

Advanced grinding with features that increase grinding accuracy and efficiency.

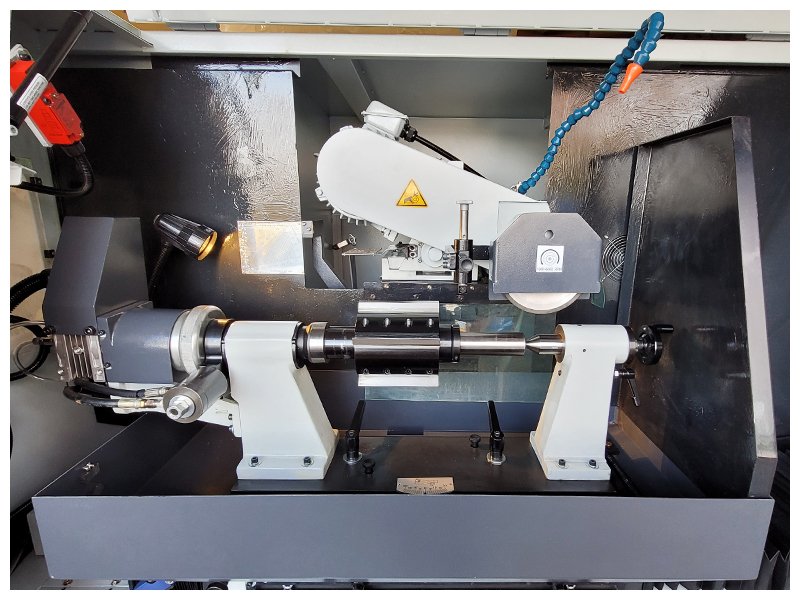

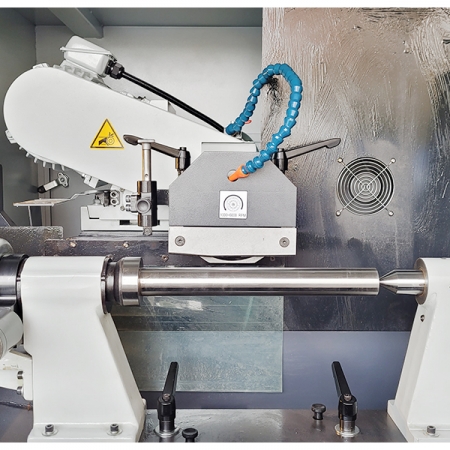

The Leadermac G320B Automatic Cutterhead Grinder is an advanced grinder that features fully automatic grinding operations and PLC control for high grinding accuracy.

Why Leadermac G320B Automatic Cutterhead Grinder?

- Extra heavy machine frame to ensure machine stability and accuracy

- Heavy safety enclosure with excellent lighting system also providing quick & easy access to machine and heads.

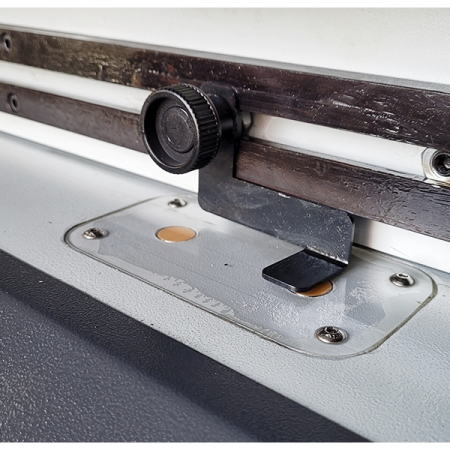

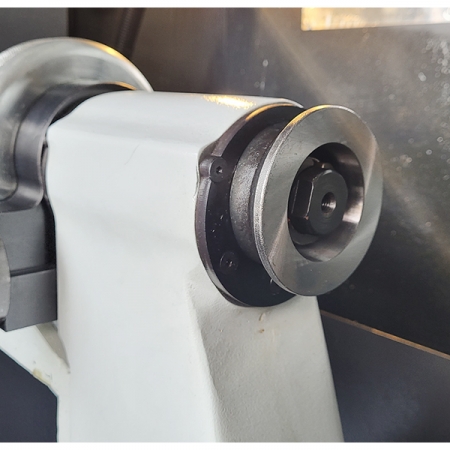

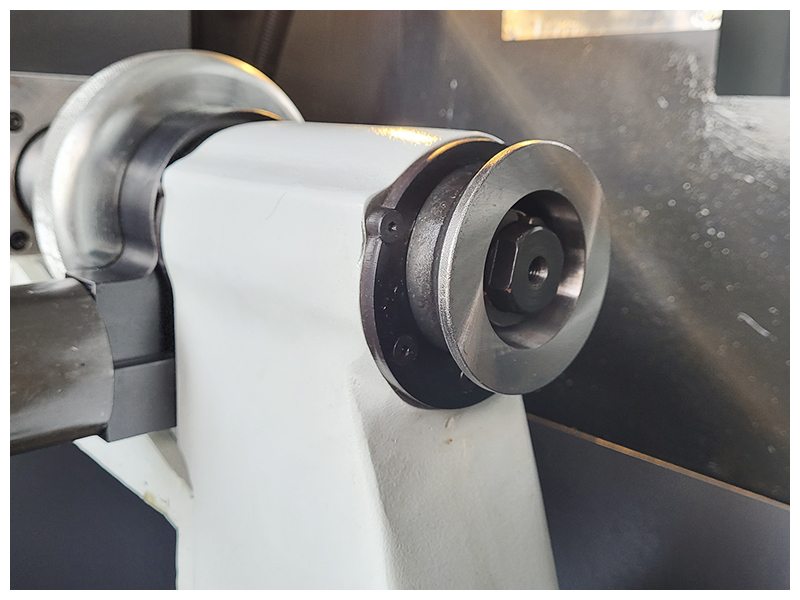

- Quick change system for head-to-head change

- Programmed for both automatic & manual operation through plc

- Indexing for any even number of knives (32 max)

- Automatic incremental variable feed speeds

- Automatic rough, finish and spark out grinding

- Variable depth of grind for rough and finish grinding

- Infinitely variable table traverse speed with servo drive with accurate length control

- Grinding wheel RPM variable from 1000-6000 rpm

- Head infeed by servo motor controlled thru touch screen

- Head infeed rapid motorized position control

- Head raise and fall with ball screw and servo motor, programmable thru touch screen

- Operator friendly touch screen control system

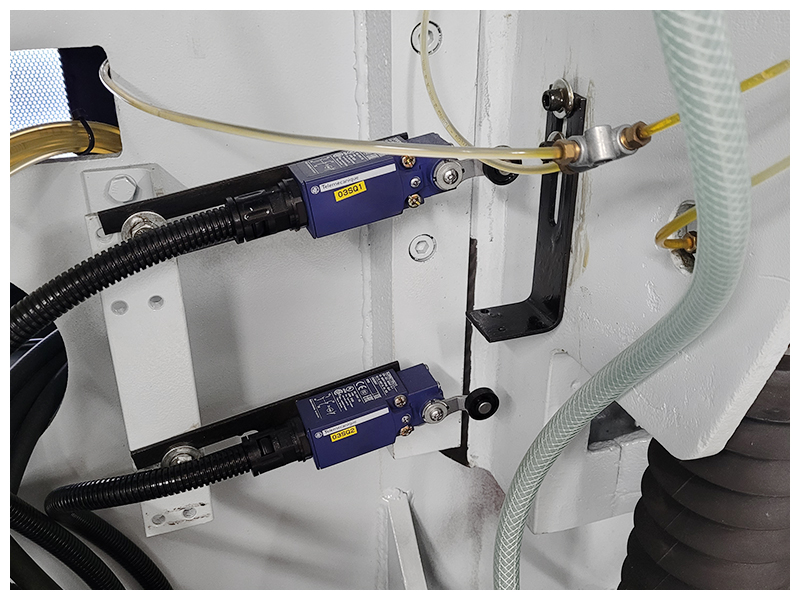

- Start/stop and emergency stop buttons

- Simple set-up gauging system to determine clearance angle and grinding requirements

- Self contained re-circulating coolant system

- Flood coolant system & coolant tank with removable magnetic filter trap

- 1 cutterhead arbor – diameter as desired

- Tool storage compartment complete with set of wrenches

SPECIFICATIONS

Machine Capacity |

||

Maximum Length of Cutterhead |

12.6” |

320 mm (longer optional) |

Maximum Swing of Cutterhead |

14” |

350 mm |

Minimum Swing of Cutterhead |

5” |

125 mm |

Maximum number of knives |

32 |

|

Grinding Wheel |

||

Diameter |

6.9” |

175 mm |

Bore |

1” |

25.4 mm |

Spindle Speed (synchronous) |

1,000 – 6,000 RPM |

|

Machine Table |

||

Traverse Speed (infinitely variable) |

2 – 10 FPM |

0.6 – 3m/min |

Indexing Unit |

||

Indexing Rate |

1 RPM standard and 4 RPM for 8 knives or less |

|

Motor Outputs |

||

Grinding Spindle |

5 HP |

3.75 kw |

Hydraulic Motor(Table Feed) |

1 HP |

0.75 Kw |

Coolant pump |

0.25 HP |

0.188 Kw |

Coolant System |

||

Tank capacity |

||

Maximum |

6.15 gal. |

23 litres |

Minimum |

3.5 gal. |

11 litres |

Machine Dimensions |

||

Height |

74.8” |

1,800 mm |

Length |

78.1” |

1,985 mm |

Depth |

64.8” |

1,645 mm |

Weight |

2,453 lbs. |

1115 kg. |

Electrics |

460/3/60 to CSA/UL Standards |

|

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.