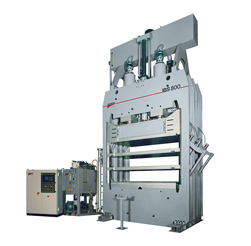

Maximum pressure and parallelism for precisely glued panel production.

The Italpresse XL series hot press is a hydraulic hot press for pressing laminates or veneer onto a substrate. The high efficiency diathermic oil recirculates though the upper and lower platens to reduce pressing time. The industrial design of the press with its massive steel beam frame along with the massive pressing cylinders exert force to ensure the proper bonding of each panel and ensures they are perfectly flat.

Why Italpresse XL Series Hot Press?

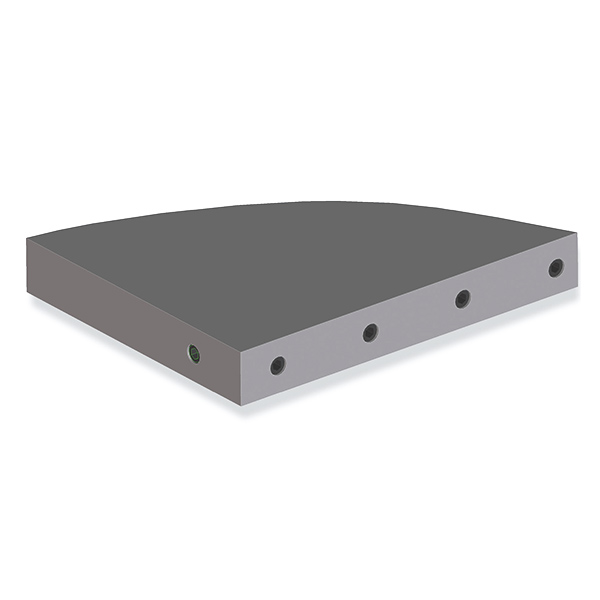

- Wide range of platen sizes available in widths from 1300 to 2200mm and lengths from 1300 to 5200mm.

- Massive steel I-beam structure to withstand high pressures

- Recirculating heating system using diathermic oil for consistent results and fast curing times

- Hydraulic pressure system capable of 50 to 250 tons for superior bonding

- User friendly touch screen interface for simple setting of the press functions

KEY FEATURES

- Welded beams press frame, calculated with high structural safety factor

- Available with single daylight or multi-daylight opening for pressing more than one panel

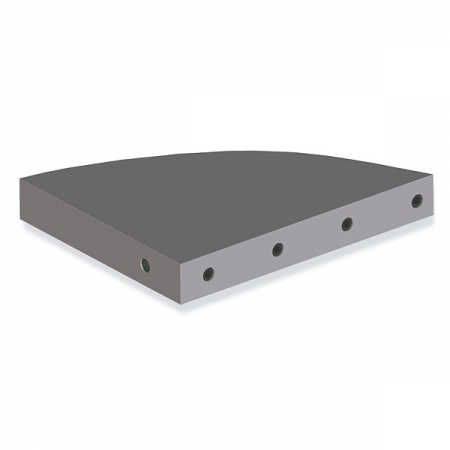

- Frame, moving platen and fixed platen are CNC machined ensure precision

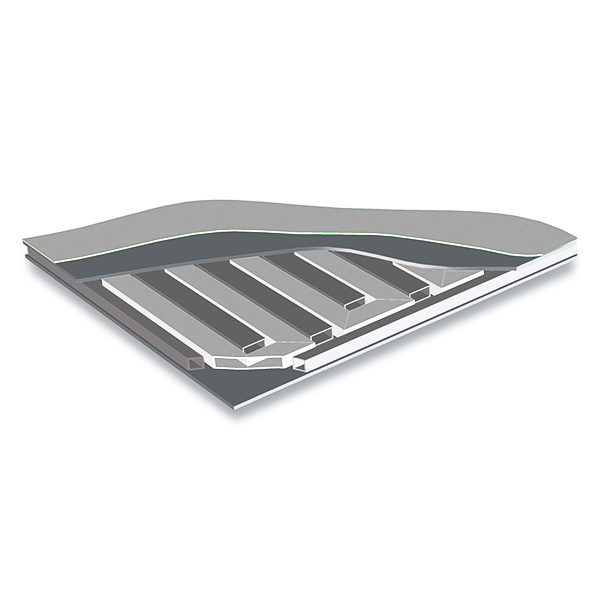

- The moving platen is a fabricated weldment of high thickness steel beams to withstand the pressing tonnage with minimal deflection

- Available with heating platens constructed with either assembled steel or solid steel to suit your pressing requirements and budget

- Platens can be covered with Mylar for easier cleanup between pressing operations

- Available with 4 to 10 hydraulic clamping cylinders

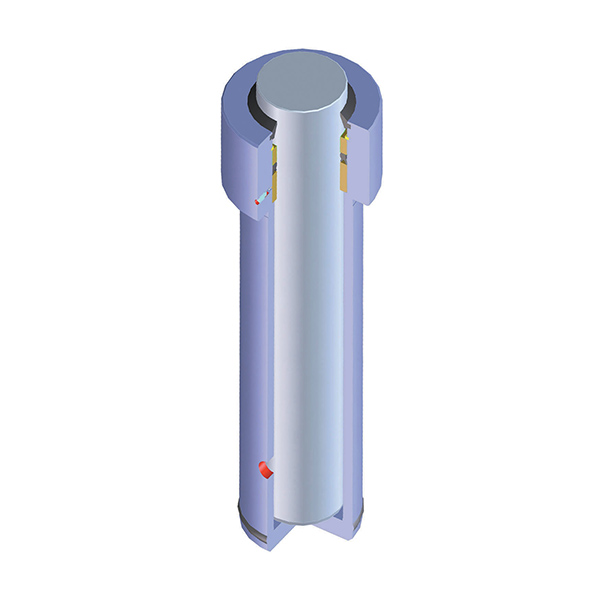

- Hydraulic cylinder castings are made with high grade steel which are robotically welded

- The rams are manufactured with chrome-plated double precision ground steel.

- Self-lubricating guides diagonally placed, for flatness control

- Rack and pinion system assures constant parallelism of the moving platen during closing and opening

- “TS 400” Touch Screen interface to control all press functions & parameters

- Graphic display of suggested positioning of panels into the press

- Memory for 200 working program which control the pressing time, pressure, piston exclusion and more

- Possibility to automatically exclude cylinders

- Automatic pressure commutation for the panel dimensions

- Fault diagnostic system

- Electronic Flatness Control (EFC) with sensors

- Two-hand timed press closure push-button switches

- Perimeter e-stop safety cable and switch

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

When does pre-milling make sense?

Machinery Solutions, Service and SupportOver the past few years, pre-milling has grown in popularity. Pre-milling is the process of machining the edge of the panel prior to applying glue. It ensures optimal edge quality before the application of edge banding, resulting in reduced glue joints and a highly aesthetic edge.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.