A Sander that is not only highly capable but thrives in multi-shift environments.

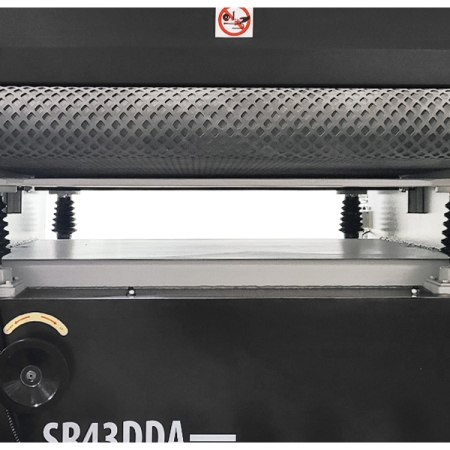

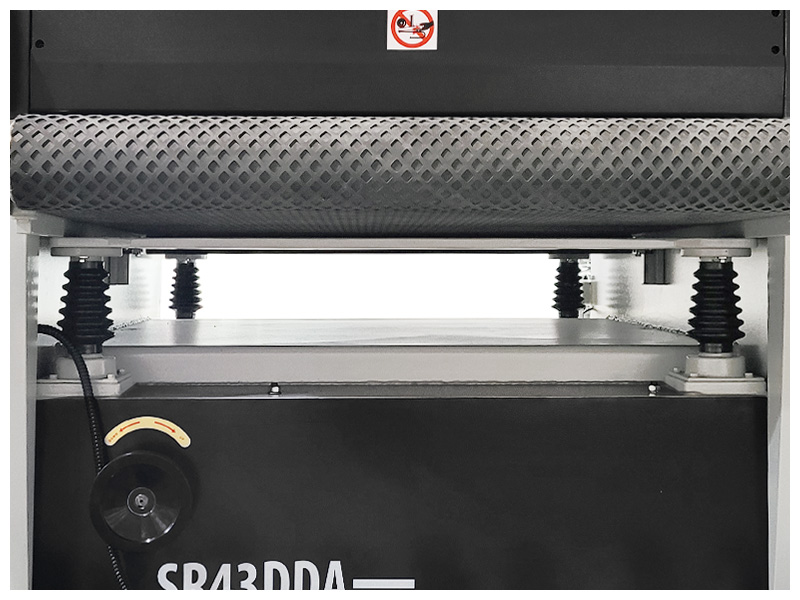

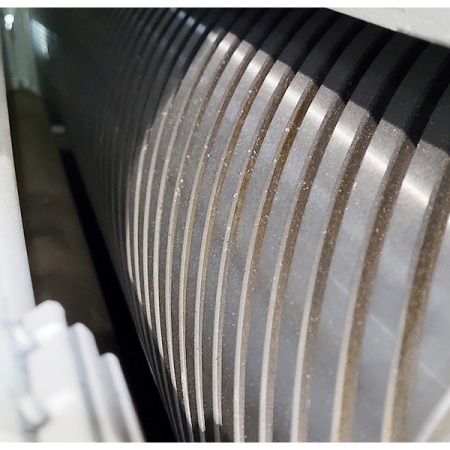

The Cantek SR43DDA 43″ three head widebelt sander combines a solid machine frame with unparalleled machine features resulting in superior sanding quality and reliability. The three sanding heads result in fewer passes through the sander resulting in increased efficiency and throughput. The first sanding head is a robust steel contact drum with calibration capacities and durability. The second head consists of a versatile rubber contact drum. The third head is a combination head with a rubber contact drum and adjustable sanding platen to perform further calibration or finish sanding with finer sanding grits. The 75″ long belts allow for longer runs between belt changes. The quick setting digital thickness control allows for accurate, automatic table adjustment for precise sanding results.

Why Cantek SR43DDA 43″ three head widebelt sander?

- Robust machine structure with cast iron head assemblies for superior sanding results

- Dual sanding heads for increased productivity

- Accurate digital thickness control with both Inch and Metric settings allows the operator to key in the desired thickness and the table will automatically move into position

- Caliper thickness setting unit for fast setup to your workpiece

- “D” sanding unit= 10” diameter steel contact drum

- “D” sanding unit = 10” diameter 75 durometer contact drum available in Rubber

- “A” Sanding Unit = 5 1/2” diameter 65 durometer Combination head with rubber contact drum and adjustable 3” sanding platen ideal for calibrating and finish sanding

- Heavy-duty welded steel frame with cast iron sanding head assemblies for vibration-free sanding.

- Dual rubber-covered pressure rollers on infeed and outfeed for consistent material hold down.

- High-quality rubber conveyor with automatic pneumatic belt tracking.

- Extended infeed bed with two table rollers.

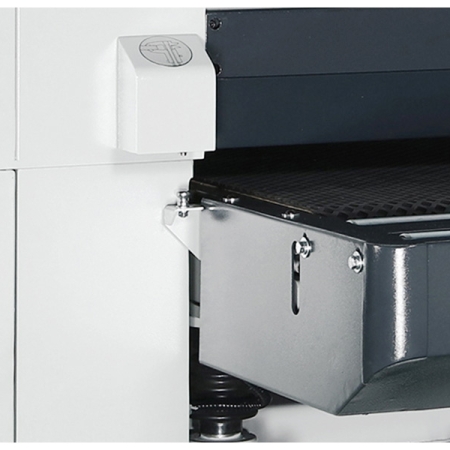

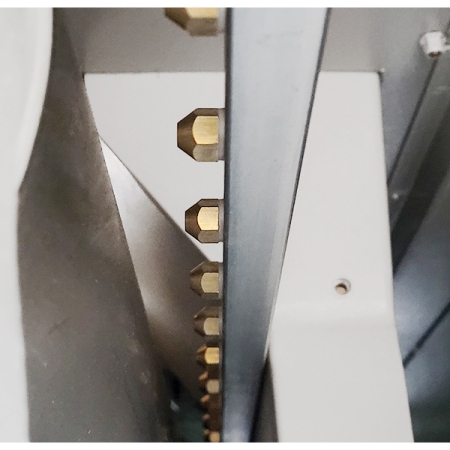

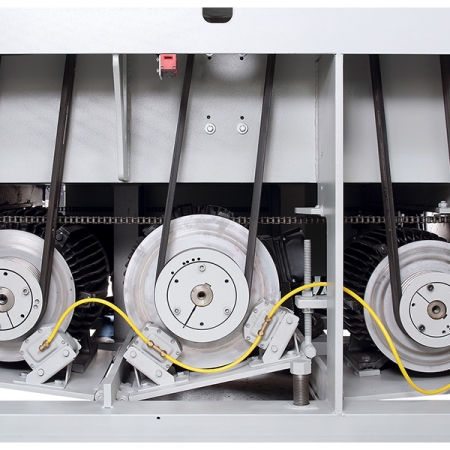

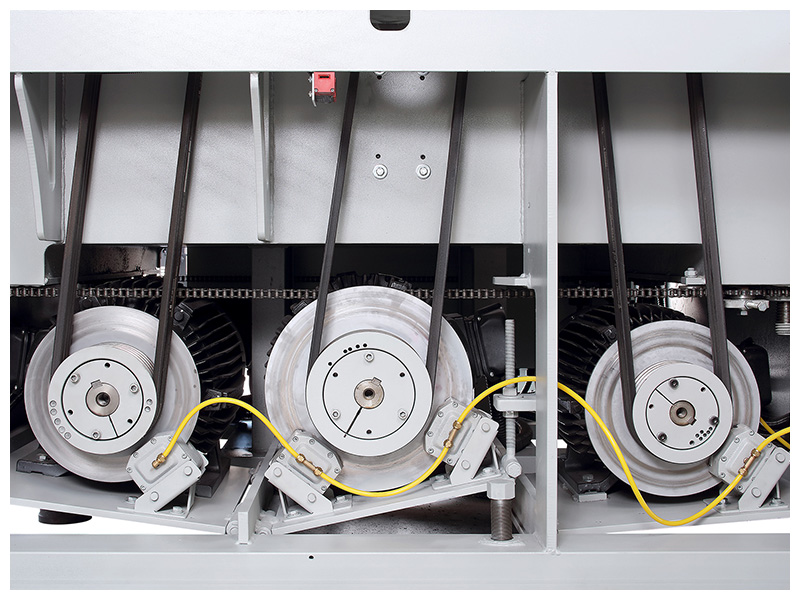

- The table is adjusted using four heavy-duty jackscrews driven by a robust chain system.

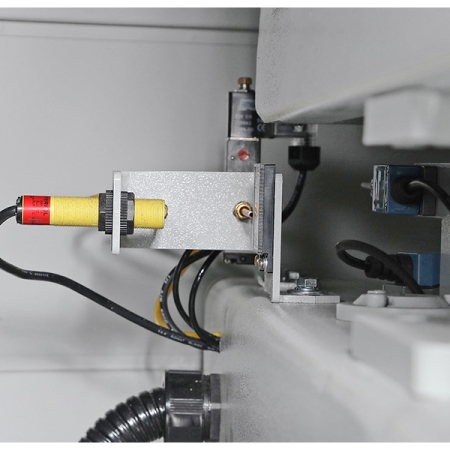

- Automatic caliper thickness setting.

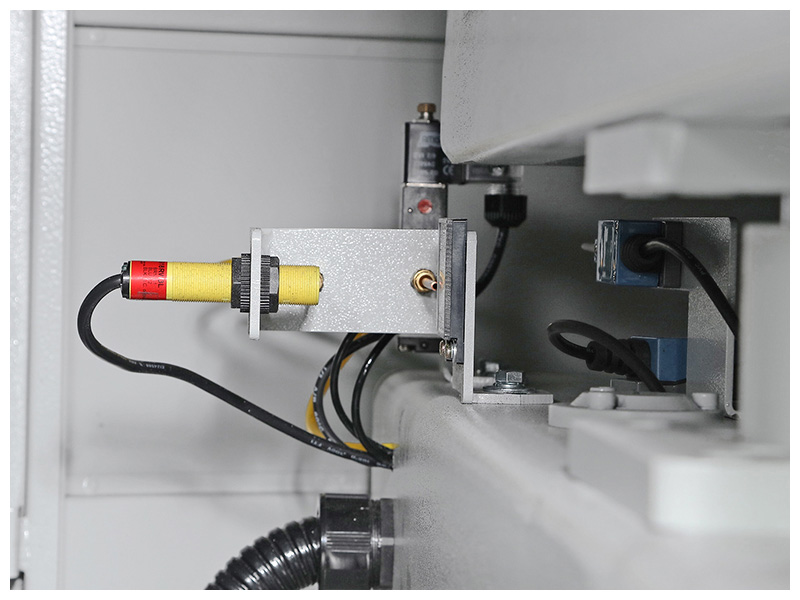

- Electronic sanding belt tracking.

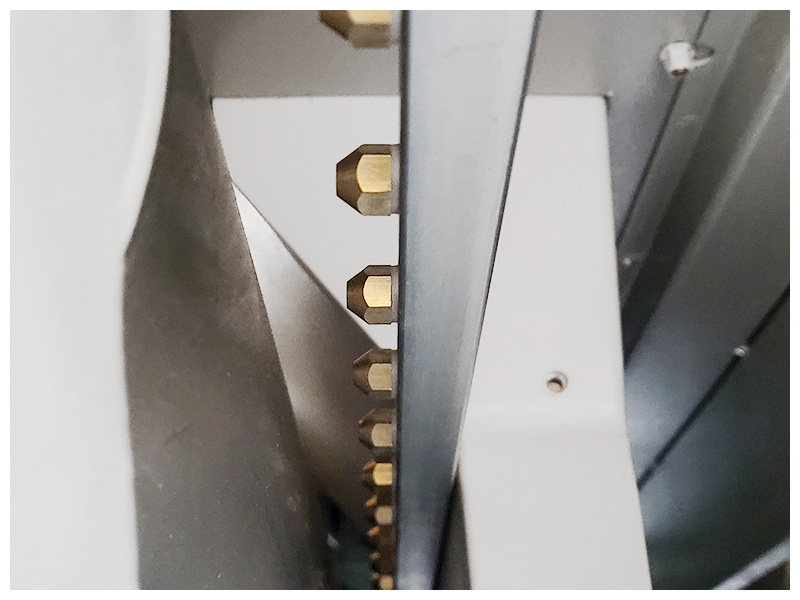

- Pneumatic belt tensioning & quick release outboard support for fast belt changes.

- Automatic disc brakes for the sanding heads allow for fast belt changeover.

- Safety switches on all access doors.

- High-quality Schneider electrical controls and top quality pneumatics

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.