Versatile edge sander for doors, drawer boxes and more.

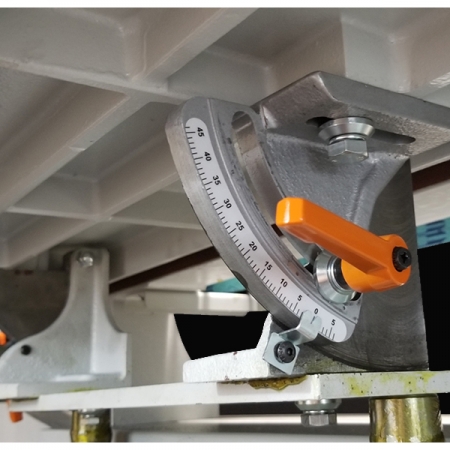

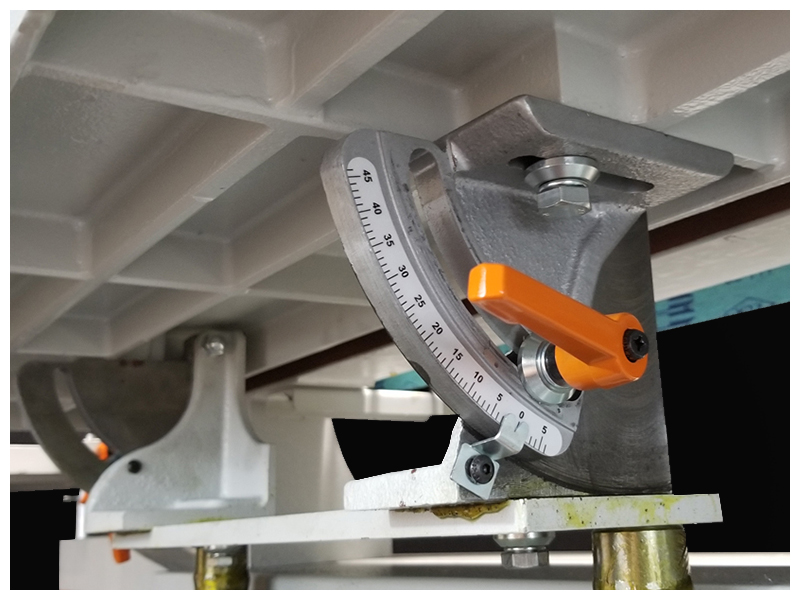

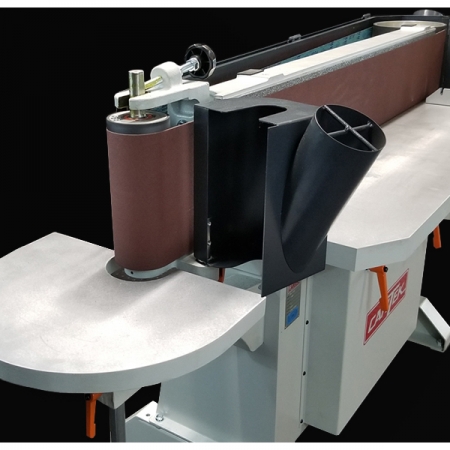

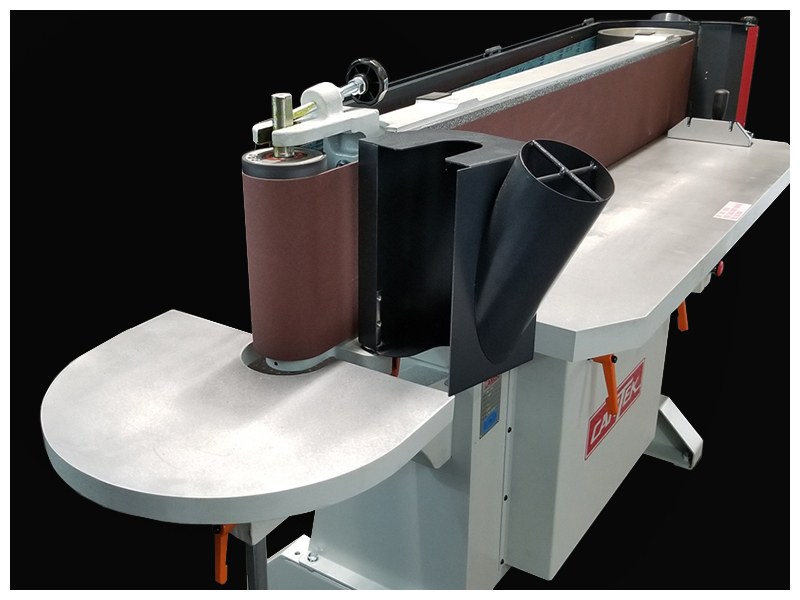

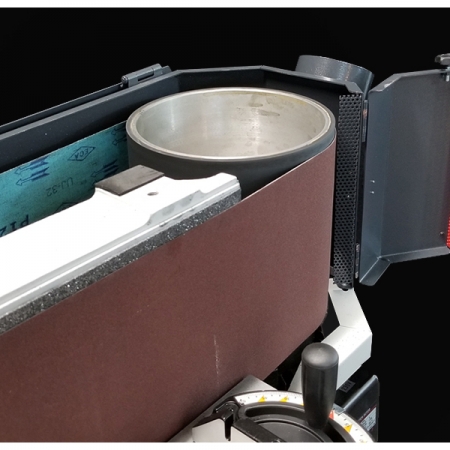

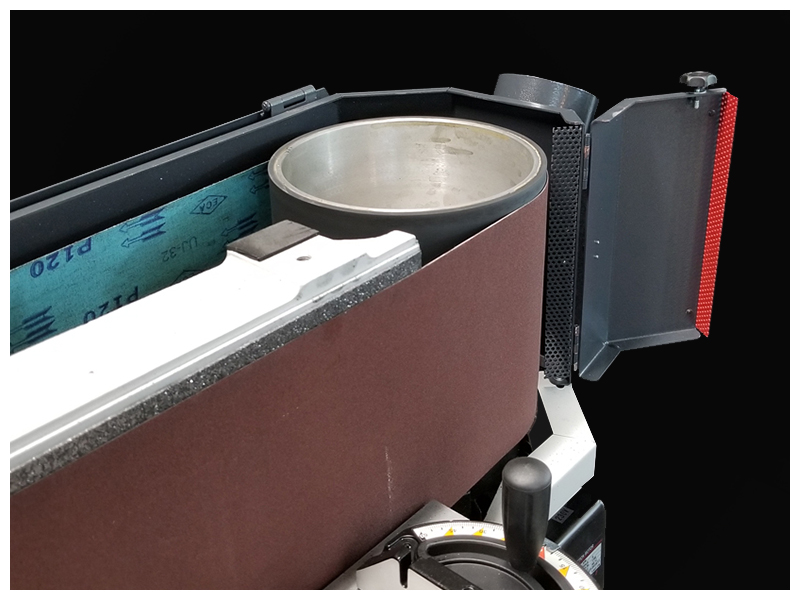

The Cantek PW120E Oscillating Edge Sander is designed for the most demanding sanding applications. With its powerful 3HP motor it can perform under industrial requirements. The oscillating belt ensures optimum sanding quality and extended belt life. Its versatility lies in the number of functions which can be done on this single machine. The industrial cast aluminum table can be easily tilted with positive stops of 45° and -5° so you can easily sand straight or miter edges. Additionally, the front table is spring loaded making it effortless for the operator to set the table height in order to utilize the full sanding belt. The 9” high sanding belt makes it ideal for sanding thicker furniture parts or drawer boxes. The additional tiltable cast aluminum end table with removable guard allows for inside contour sanding.

Why Cantek PW120E Oscillating Edge Sander?

- Oscillating sanding belt produces optimum sanding results with extended belt life as it runs cooler during sanding operations while using more of the belt

- Powerful 3HP motor for even the most demanding sanding requirements

- Cast aluminum front and rear tables are adjustable and tiltable for straight or bevel sanding

- Contoured end table with 4” pulley allows for sanding the inside radius of a workpiece

- 48” x 9 ½” cast iron platen is covered with graphite cloth providing a wide & stable sanding area which is perfect for doors, furniture parts, and even longer parts

- Spring loaded front table allows for effortless adjustment of the table to the desired position on the belt

- 8” travel of the front table allows for maximum use of the sanding belt for prolonged life

- Oscillating system is driven from main motor by gear mechanism

- Quick and easy belt changes and belt tracking adjustment

- Two 4″ dust chutes for dust collector connection

- Magnetic switch to CSA/UL standard

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.