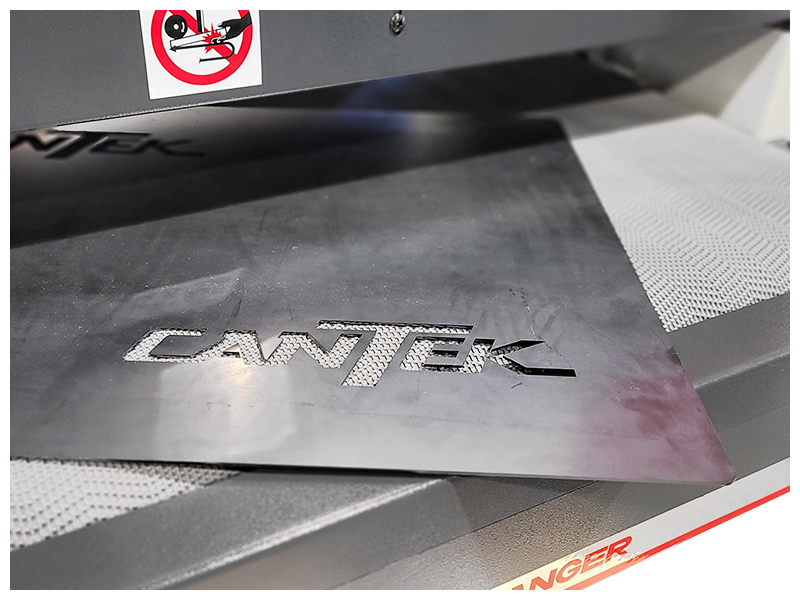

Compact Metal Wide Belt Sander for increased efficiency during oxidation and slag removal.

The Cantek MT43D 42” Single Head Metal Widebelt Sander is designed to be asy to use and durable for the removal of oxidation, deburring, and slag. It comes equipped with a single rubber contact drum with efficient material removal capabilities. The 7” contact drum is equipped with pneumatic belt tensioning for fast belt changeovers. The precision digital thickness control allows the operator to accurately enter the desired thickness which moves the table precisely in to position for repeatable results. The industrial welded steel frame and powerful features all come in a compact package making ideal for smaller to midsized shops.

Why Cantek MT43D 42” Single Head Metal Widebelt Sander?

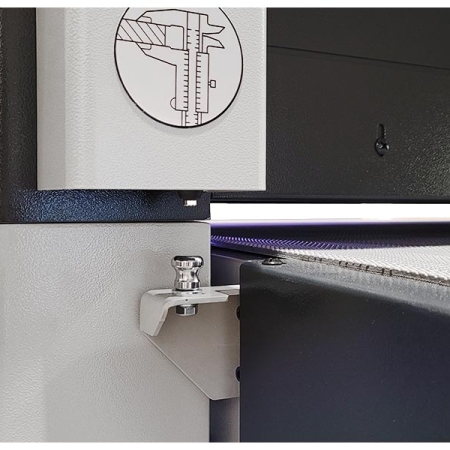

- Accurate digital thickness control with both Inch and Metric settings allows the operator to key in the desired thickness, and the table will automatically move into position.

- Single-head sanding unit with a 7″ rubber contact drum for oxidation, slag removal and deburring metal sanding applications.

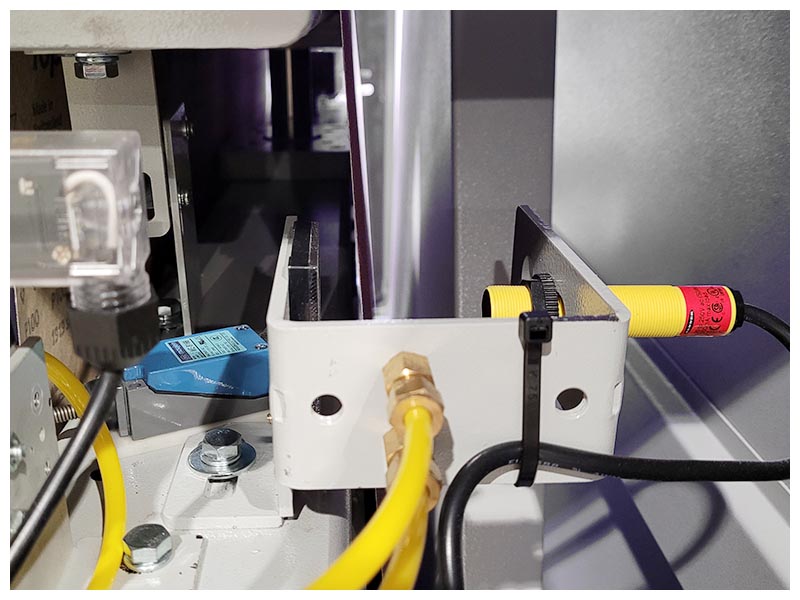

- Pneumatic belt tensioning with quick-release outboard support to facilitate fast belt changes.

- Small footprint making it ideal for a small to mid-sized production shop

- Electronic belt tracking for optimum belt life and sanding results.

- Ammeter for load monitoring to ensure the proper amount of material is removed according to the selected grit.

- Disc brake on the main motor allows for faster belt changes.

- Double infeed and outfeed pressure rolls for superior part hold down.

- Table raising jackscrews.

- Material over-height limit switch.

- Interlocks are located on all access doors.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.