Compact Metal Wide Belt Sander for increased efficiency during oxidation and slag removal.

The Cantek MT37DD 36” Two Head Metal Widebelt Sander is designed to be easy to use and durable for the removal of oxidation, deburring, and slag. It comes equipped with two rubber contact drums with superior material removal capabilities. The dual sanding units allow for the use of different grits in a single pass which cuts down on the overall sanding time. The precision digital thickness control allows the operator to accurately enter the desired thickness which moves the table precisely in to position for repeatable results. The industrial welded steel frame and powerful features all come in a compact package making the MT37DD ideal for smaller to midsized shops.

Why Cantek MT37DD 36” Two Head Metal Widebelt Sander?

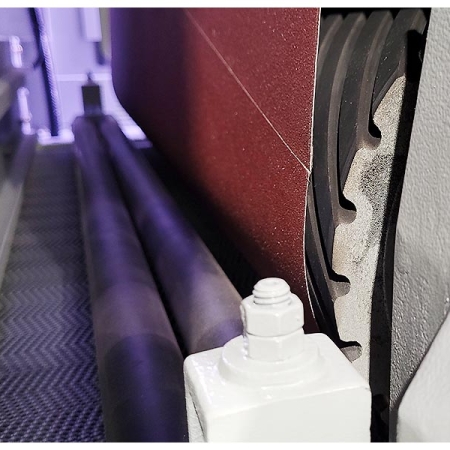

- Two sanding units each with a 8″ diameter rubber contact drum for superior material removal

- Accurate digital thickness control with both Inch & Metric settings allows the operator to key in the desired thickness, and the table will automatically move into position.

- Variable feed speed for optimal feed rate control for premium sanding results

- Industrial welded steel frame

- Small footprint takes up less valuable floor space

- Electronic belt tracking for optimum belt life and sanding results.

- Ammeter for load monitoring to ensure the proper amount of material is removed according to the selected grit.

- Disc brake on the main motor allows for faster belt changes.

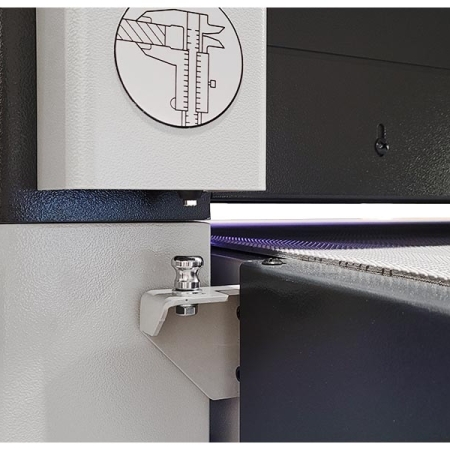

- Pneumatic belt tensioning with quick-release outboard support to facilitate fast belt changes.

- Dual infeed, outfeed, and intermediate pressure rolls for superior part hold down.

- Four table raising jackscrews.

- Material over-height limit switch.

- Interlocks are located on all access doors.

- Caliper thickness device for quick measurement of material.

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.