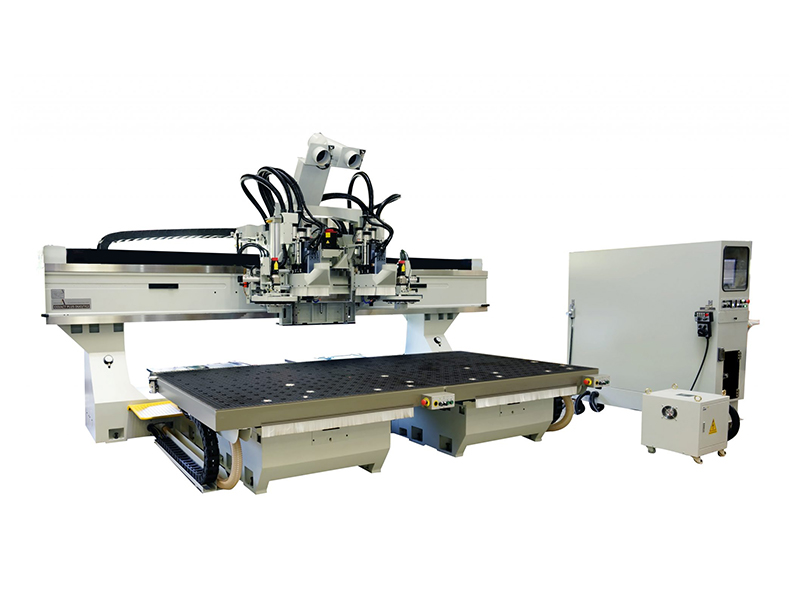

Industrial CNC Router for the most demanding routing applications.

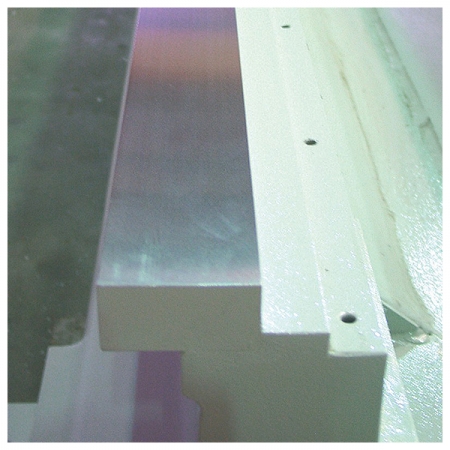

The Anderson EXXACT Series CNC Router is a Moving Table 3 or 4-axis machining centers that sets a new level of CNC accuracy and machining performance. The combination of a highly rigid base, steel weldments and castings and high accuracy Servo System make the EXXACT an ideal choice for machining wood, MDF, plywood, plastic, aluminum and composite materials.

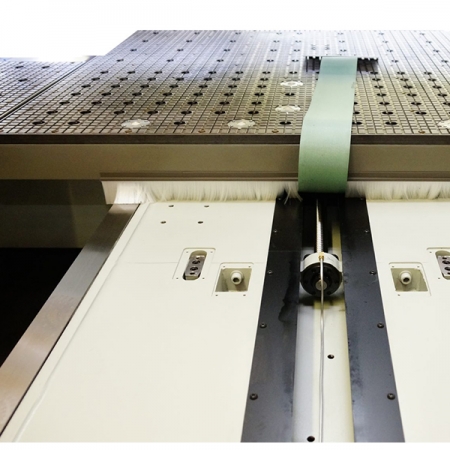

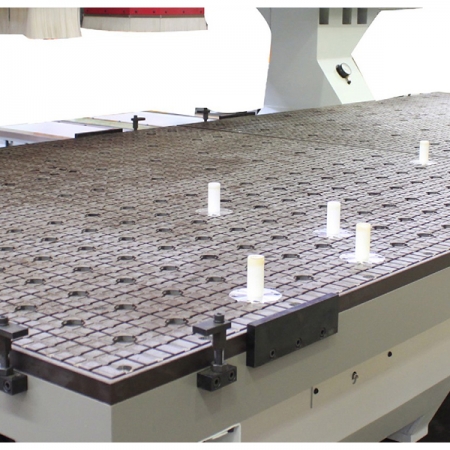

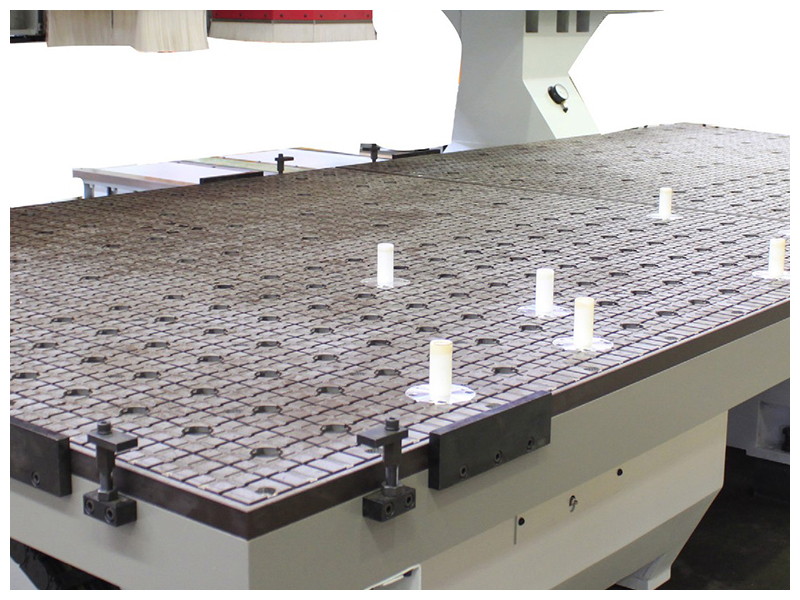

The Anderson fixed bridge and moving table design provides easy machine access. The webbed steel substructure remains smooth and rigid while cutting in X, Y and Z-axis. The EXXACT CNC machining centers set a new standard in high-speed CNC machining as it is designed to handle heavy duty CNC machining in various thicknesses flat and aluminum plate. CNC Controls include Ethernet options to provide remote technical support; optional C-axis is available. Work piece holding flexibility is provided by optional clamping, grid or manifold vacuum systems. The EXXACT CNC Machining Center utilizes an industry standard G-code for control functions that allows easy interfacing with all major CAD/CAM software and industry standard solid modeling software packages.

Why Anderson EXXACT Series CNC Router?

- Massive structure for heavy cutting operations

- Precision industrial box ways for added stability in the toughest environments

- Fixed bridge with moving table(s)

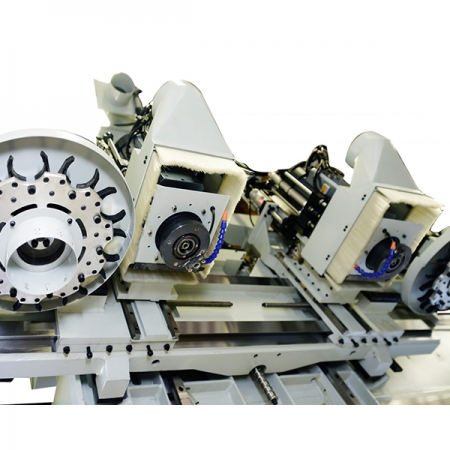

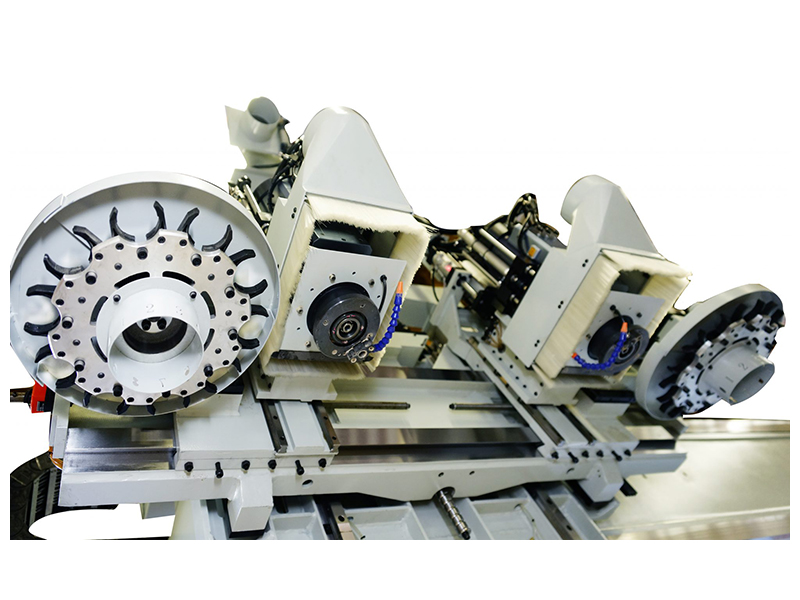

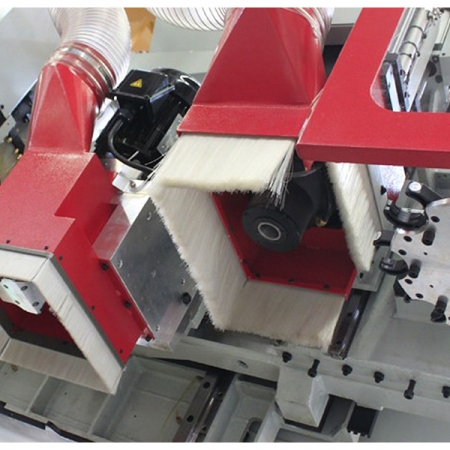

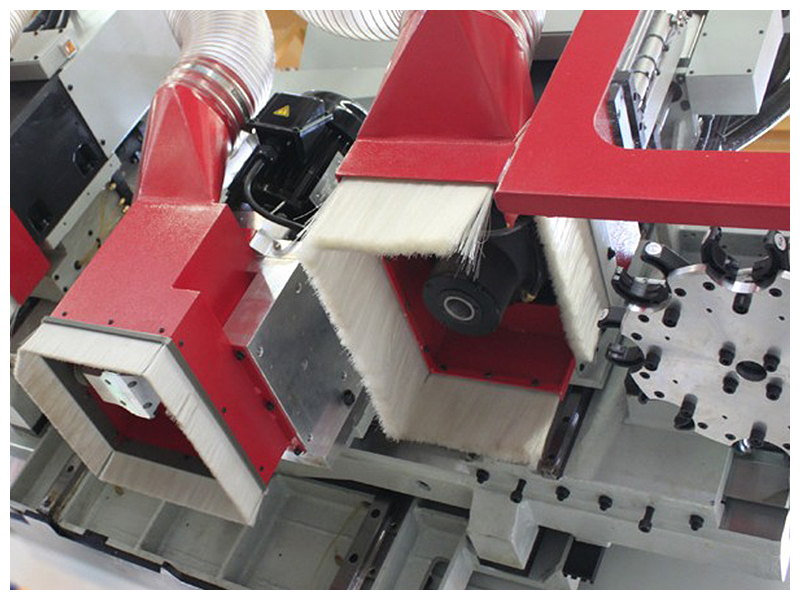

- Various head configurations available with wide range of spindles, tool changers, drill heads and more

- Available with single or dual moving tables

- Fanuc PC Front end controller

- Fanuc Servo drives

EXXACT-TC

- One ANDI HSK-63F spindle with 10 position tool carousel. Standard spindle configuration is a 15 HP Air cooled dynamic (travels with spindle) router spindle 0-24000 rpm. 10, 12 or 16- position automatic tool changers are options. Robotic Arm Tool Changer and Water-Cooled spindle versions are available.

EXXACT-TC+D

- One ANDI HSK-63F spindle with 10-position tool carousel and one 32 mm 5×5 Vertical Drill Block.

- Optional horizontal drills and grooving saw.

EXXACT-TC2

- Two ANDI HSK-63F spindles each with 10- position tool carousel.

EXXACT-TC2+D

- Two ANDI HSK-63F spindles with 10-position tool carousel.

- One 32 mm 5×5 Vertical Drill Block.

EXXACT-TC2+D2

- Two ANDI HSK-63F spindles with 10-position tool carousel.

- Two 32 mm 5×5 Vertical Drill Block

Dovetails, what’s the big deal?

Machinery SolutionsOnce you open the drawer and see the dovetail design, it elevates your product in the consumer’s eye. But why dovetail machine is right for my operation? When deciding to produce your own drawer boxes, a number of factors come into play when selecting the equipment required.

CNC Series: How does cutting speed affect your cutter life?

Machinery SolutionsIf you want to extend your cutter life, you need to produce an optimum chip load. And to achieve faster feed rates, you need to have axis servo drives large enough to move the machine’s mass at a rapid speed.

Kingswood Cabinets. A true commitment to growth.

Case Study, Machinery Solutions, Service and SupportAkhurst is very proud of our involvement in the plant expansion of Kingswood Cabinets of Calgary, Alberta. Kingswood recently relocated to a new state-of-the-art manufacturing facility.