Machine Information

The Hoffmann X-20 bench-top routing machine is designed for the advanced amateur and hobby shop as well as for smaller customer woodworking operations.

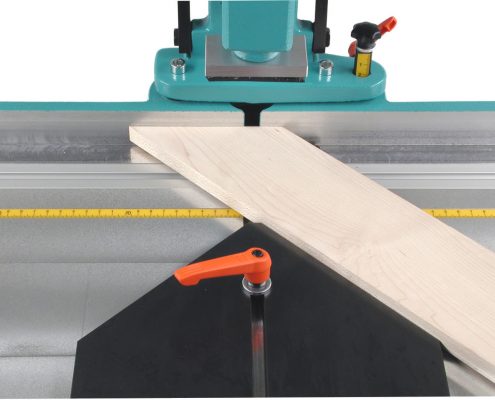

Compared to the fixed angle X-10 model, the machine can be used for a wide range of joining operations, including miter joints with different angles, end-to-end and T-joints, etc.

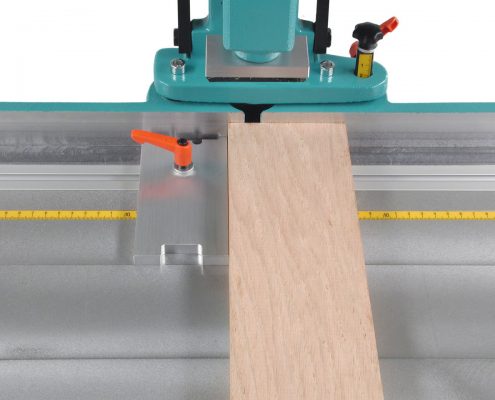

Compared to the smaller and lighter X-15 model, the machine has a larger table (and therefore more material support) and it is capable of processing larger material.

The maximum material thickness is 4” and the maximum routing stroke is 3”.

Machine Design and Overview:

The Hoffmann X-20 bench-top routing machine is equipped with a high speed router motor, located at the center of the machine. The routing operation is started by pulling the main lever. A hold down plate is lowered onto the workpiece, pressing it on the table and holding it in place. Further pulling lifts the motor carriage up until the preset cutting height is reached.

The motor is switched on automatically by pulling the lever, it is switched off again when the lever is returned to the home position. Two springs in the lever mechanism counteract the pull down force, which ensures controlled movements throughout the routing process.

Output is approx. 16 routing strokes per minute, which translates into 2 completely processed rectangular frames. These numbers include material handling, but obviously depend on routing depth, feed speed, material flow and operator performance as well.

The supplied router bit is solid tungsten carbide, made to exacting specifications. Depending on the routing depth and the material to be routed, the useable cutter life is approx. 10,000 strokes. Every machine is shipped with a tool kit and set-up jig, which allows a router bit change in only minutes. Diamond cutters are also available.