Compact wood waste grinder with larger diameter rotor

Wood is a valuable raw material that can be used down to the last chip, and this is what WEIMA WL6S Wood Waste Shredder delivers. When processed into wood chips, the wood waste can be used for direct energy generation in combustion plants or for the production of briquettes. WEIMA’s wood waste shredders are ideal for reducing bulky scrap into a more manageable size which can greatly reduce your waste disposal costs.

Why Weima WL6S Wood Waste Shredder?

- Stop paying to dispose of waste bins that are mainly just air!

- By reducing your waste to chips you can maximize the use of your disposal bin which greatly reduces your disposal fees

- Waste can also be reduced for direct energy generation or in the production of briquettes

- The global popularity of this shredder series assures high reliability at a competitive price to performance ratio.

- Typical applications include all kinds of hardwood and softwood, waste wood, OSB and MDF, veneer, plywood, stairs, doors and pallets.

KEY FEATURES

- High horsepower, low RPM can shred a wide range of waste including

- Motor power from 22 to 37 kW

- Robust machines construction giving it a long operating life

- The shredded wood can be collected by a dust collector system or discharged onto a traditional conveyor

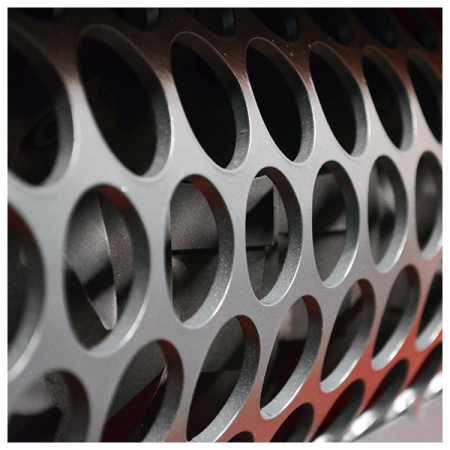

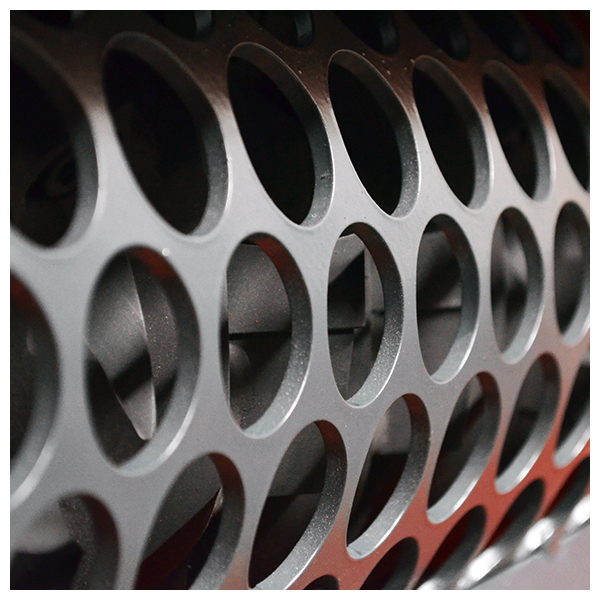

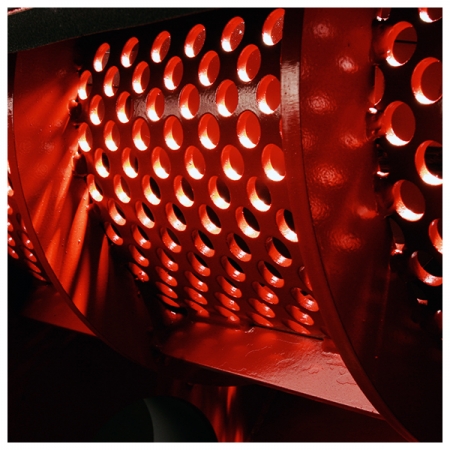

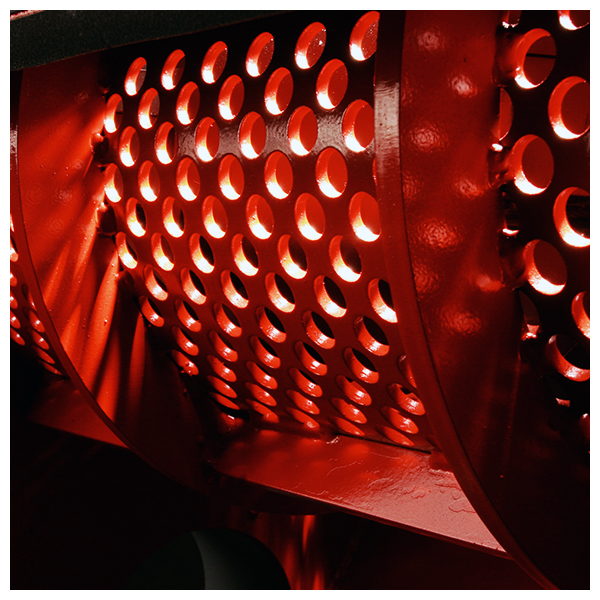

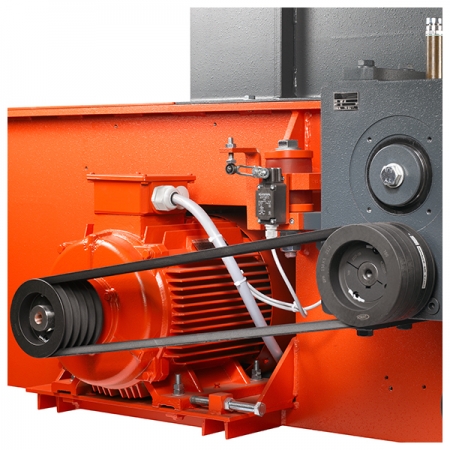

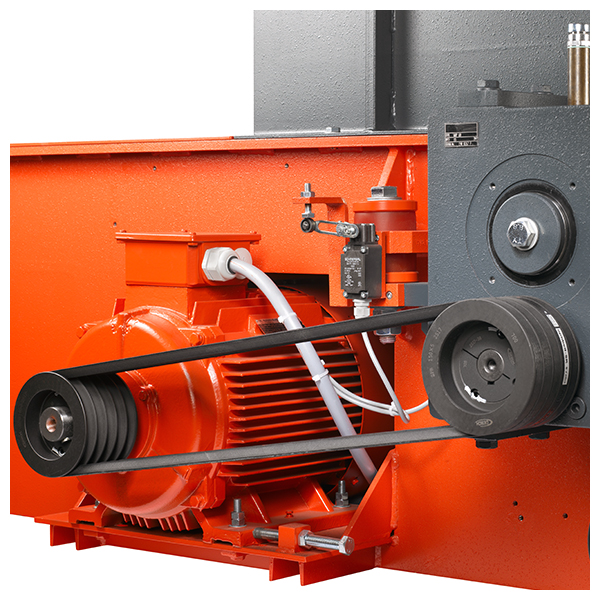

- The profiled innovative “V” Rotor is made of solid material and mounted on stable rotor bearings

- Special blade holders are welded into milled blade pockets around its circumference

- The cutting knives are set into these and screwed on from the back ensuring quick and easy blade changing

- Nails and screws are simply shredded along with the wood waste and can later they can be easily separated with an optional cross-belt magnet upon discharge

SPECIFICATIONS

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.