Powerful horizontal wood shredder greatly reduces your disposal costs.

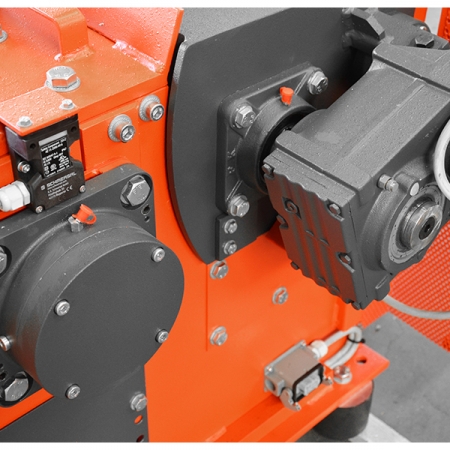

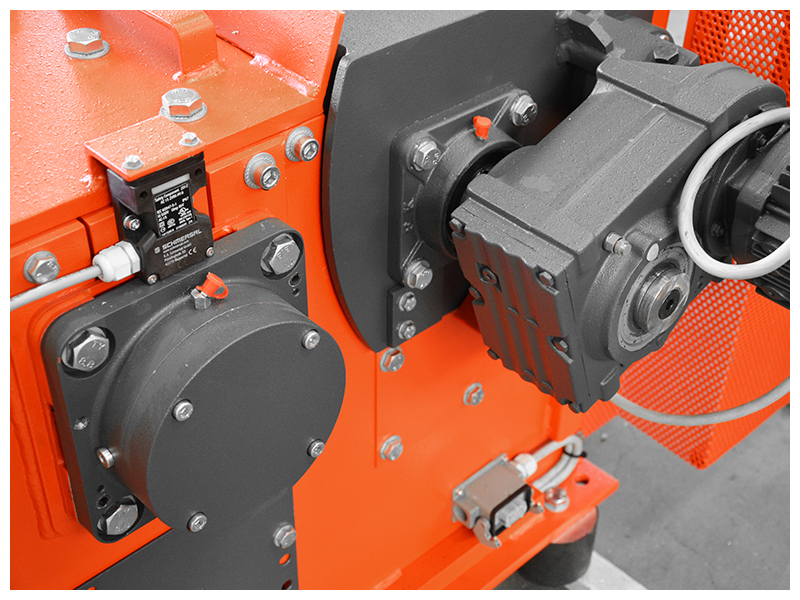

The Weima Leopard Series Horizontal Wood Waste Shredders are part of Weima’s horizontal single-shaft shredder series designed for shredding linear wood waste. This shredder is great for turning solid wood waste into chips. The shredded material is placed into a vibratory infeed conveyor that is the same width as the machine itself. This conveyor feeds the material consistently into the shredder. Horizontal shredders are known within the wood industry and are found in many woodworking shops. In addition to its compact design, the WEIMA horizontal shredders have a low rotor speed, which helps with noise control. This makes it possible for the machine to be placed directly near the woodworking machine rather than under it for the processing of MDF and solid wood.

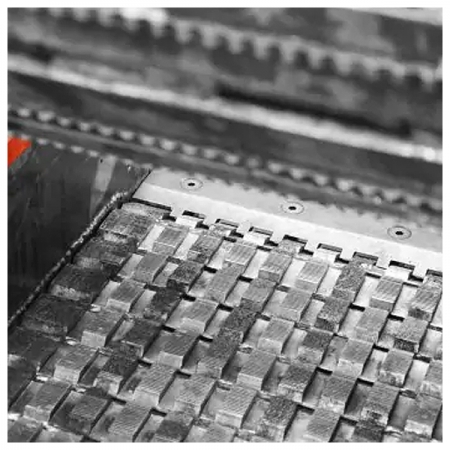

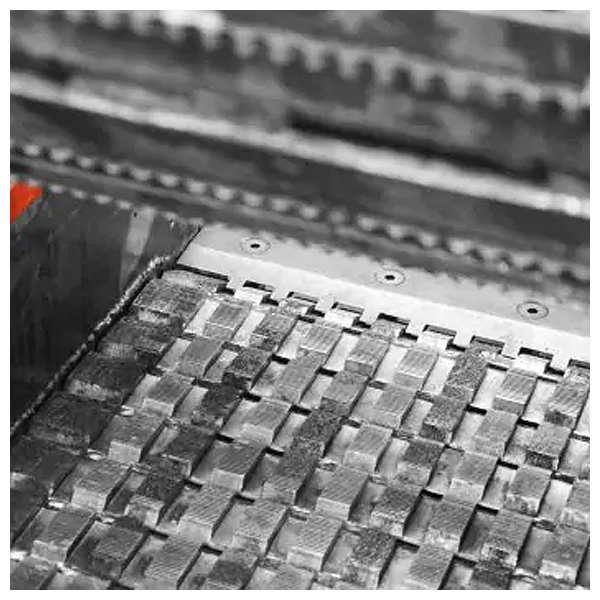

The material to be shredded is fed into a feed channel with the same width as the shredding machine. Material intake is assisted by in feed rollers which transport the material to the rotor. Material in feed operates according to load, i.e. if the shredding roller is consuming too much power, the feed system switches off automatically until the material in the system has been shredded. This procedure is repeated until the parts are shredded. The size of the chips is determined by a screen positioned around the rotor.

Why Weima Leopard Series Horizontal Wood Waste Shredders?

- Small footprint allows it to be placed next to the equipment creating the wood strips

- Powerful shredding capacity

- 4-sided indexable knives with concave cutting edge for maximum shredding efficiency

- Can be pair with vibrating infeed conveyor for automatic feeding of wood strips

- Connected to chip extractor for efficient waste removal

- Innovative “V” Rotor for optimum cutting

- Knife / Counter knife tolerance protection

- Rotor manufactured in industrial grade steel

- Minimum wear

- Minimum thermal impact

- Optimum in feed of material

- High throughput with concave knives

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.