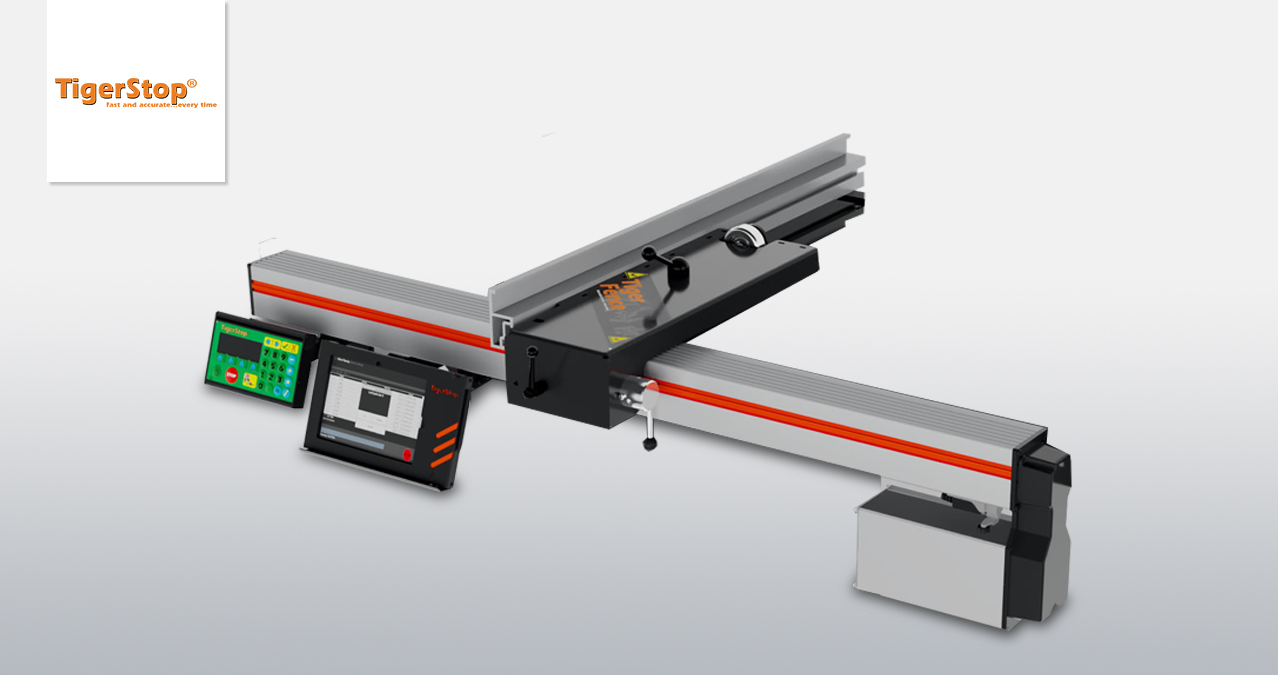

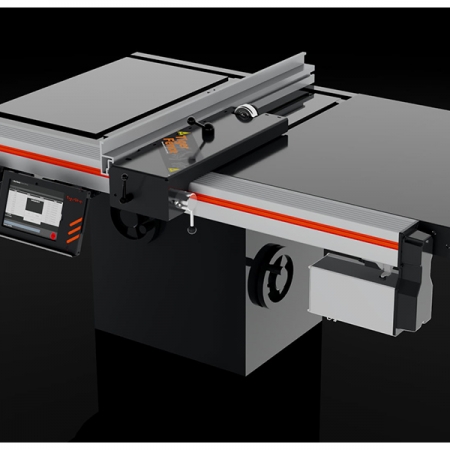

Fully Automated Rip Fence for Your Table Saw and Straight Line Rip Saw

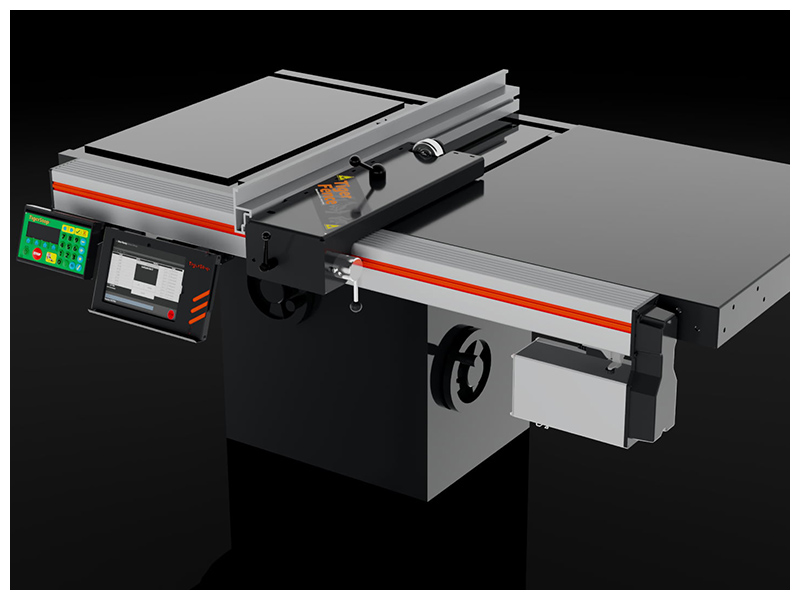

The Tigerstop TigerFence Rip Fence brings speed, precision, and productivity to your table saw. It adds automation that can be controlled from one side of your saw and has a repeatable accuracy of +/- .003 inches (.07mm). Walking around your table saw or sliding table saw to adjust an inexpensive manual fence may seem like a small inconvenience, but over the lifetime of the saw, it adds up to serious wasted time. We all know that time is money. Saving 30+ seconds of set up time on each cut, paired with increased accuracy, and reduced scrap waste, adds dollars to your bottom line and increases in quality. Most users see up to 30% more productivity out of their saw with TigerFence.

Why TigerStop TigerFence Rip Fence?

No More Set Up Time

TigerFence moves to the desired dimension at the press of a button. No more walking to adjust a manual fence, measuring and marking material, and wasting precious labor hours.

Fast and Accurate…Every Time

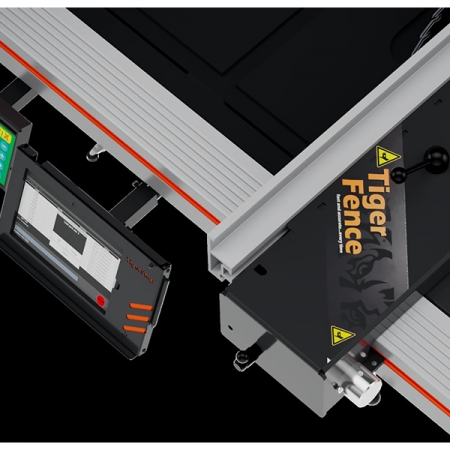

TigerFence is designed with precision linear bearings, ensuring a rigid and dead accurate position every time. TigerFence has a repeatable accuracy of +/- .003 inches (.07mm) so today’s parts will be the same size as tomorrow’s parts.

Adaptable

If you need more production, don’t buy a new saw. Turbocharge your existing table saw with TigerFence! TigerFence can easily attach to almost any table saw, sliding table saw, or straight line rip saw.

Easy to Train

An unskilled operator can be trained to use TigerFence to accurately position material in less than 10 minutes.

Two Sizes

TigerFence comes in a standard size with a working length of 51″ and an overall length of 62”.

TigerFence Extra comes in a working length of 70″ and an overall length of 82″.

TigerFence also comes in a variation for straight line rip saws.

- Easily adapts to straight line rip saws, table saws, and sliding table saws

- Jog Mode

- Safe zone alert when fence is close to the blade

- Calculator Mode

- Preset Function

- Metric, Decimal and Fractional Inches

- Part List Interface

- Includes standard controller that can be upgraded to a TigerTouch controller

- Upgrade to Dynamic Optimization™ software

- Upgrade to TigerLink 6 Cut List Downloading Software

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.