Touch Screen Automation for Any Sized Shop.

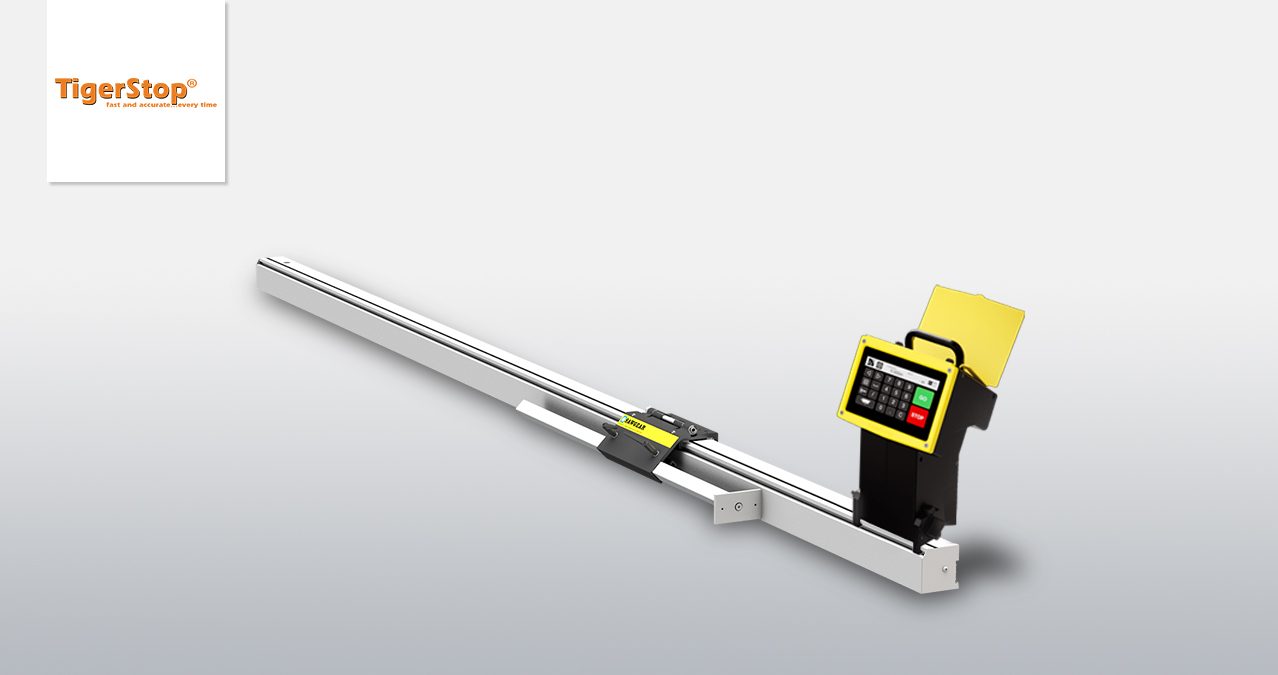

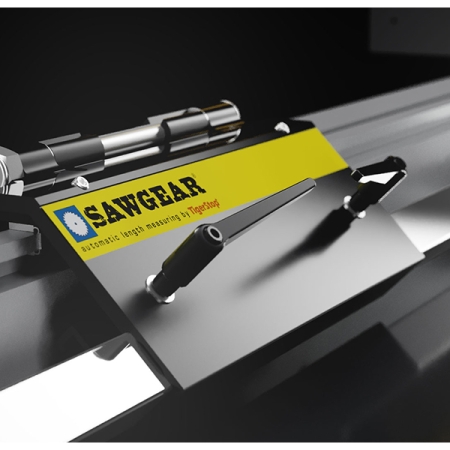

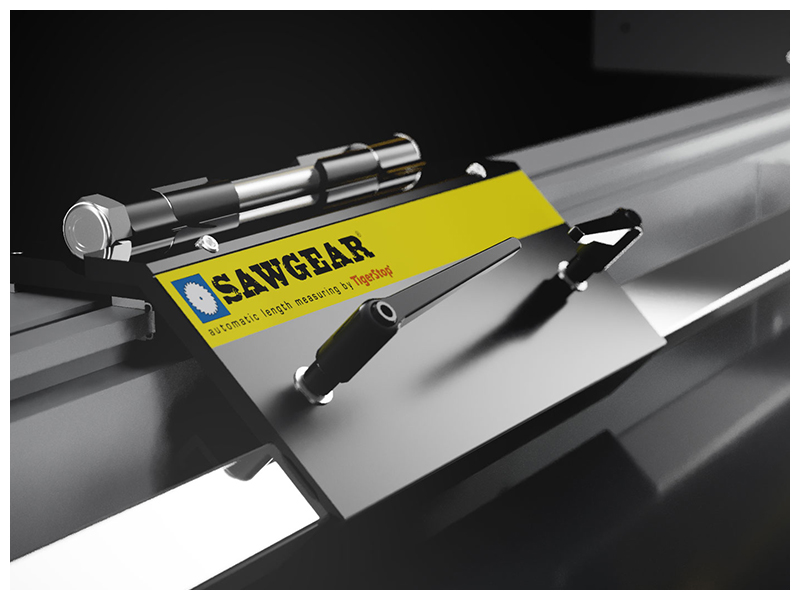

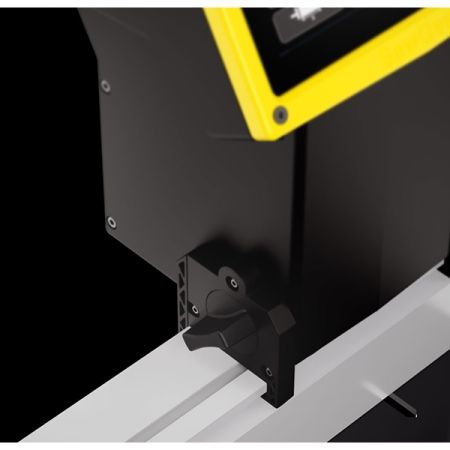

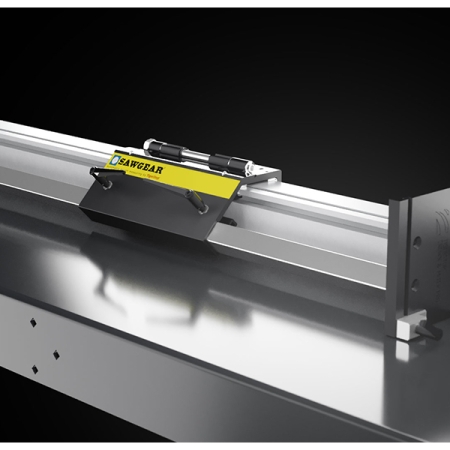

Introducing the new SawGear Touch™ by TigerStop, a feature rich touch screen controlled automated stop that easily attaches to your existing saw. SawGear Touch offers repeatable accuracy of +/- .008” and eliminates the need to rely on tape measures and manual fences. It includes downloading software, optimization software, Crown+MiterPro software, and more. Free yourself from tape measures and manual fences while producing more parts with increased accuracy.

Why TigerStop SawGear Touch Automated Stop?

Zero Set Up Time

Do away with “measure twice, cut once”. Stop relying on tape measures, manual stop blocks, and clamps in your manufacturing process.

Easy Upgrade Path

Simply swap out your old SawGear power head with the NEW SawGear Touch™ power head to access its amazing features and functionality!

100% Accuracy

The parts you cut today will be as accurate as the parts you cut next week, next month, and next year.

No More Rework

Quality control starts with SawGear Touch™ by TigerStop.

Increased Productivity

Keep your operators in the money making zone, cycling your saw, not walking back and forth measuring and marking material, double checking measurements, or worse, performing rework.

Easy to Operate

An unskilled operator can be trained to use a SawGear Touch™ to position material in under 10 minutes. A novice can learn to hang crown molding, trim, or baseboard, in less than 30 minutes!

Improved Yields

Raw material costs are rising. Using a SawGear Touch™ maximizes yields and adds profits to your bottom line.

Adaptability

SawGear Touch™ easily adapts to most cold saws, chop saws, miter saws, upcut saws, and more.

- NEW Touch Screen Control

- Easy Upgrade Path: Swap Out Your SawGear Power Head for the NEW SawGear Touch™

- New and Improved Crown+Miter Pro Software for Crown Molding, Trim, and Baseboard

- Framing Software for Window and Doors/Picture Framing

- Rabbet Compensation Software

- Single Miter Compensation Software

- Cut List Downloading Software: Holds Infinite Lists

- Dynamic Optimization Software

- Label Printing Options

- Increment Button

- Easily Toggle Between Metric and Imperial Measurements

- Convert Between Fraction and Decimals

- Adapt to Upcut Saws, Cold Saws, Chop Saws, and More!

- Works in English, Spanish, French, Dutch, and German

- Repeatable Accuracy of +/- .008″

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.