Increase your productivity and put a stop to your costly rework.

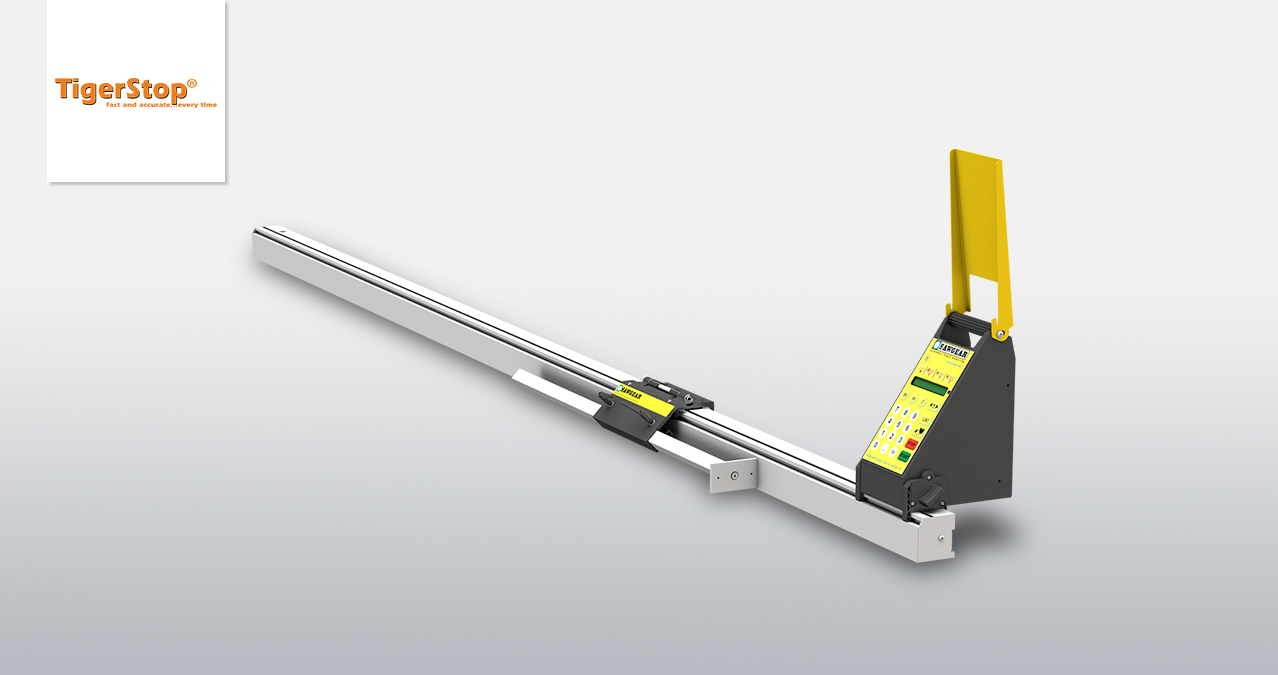

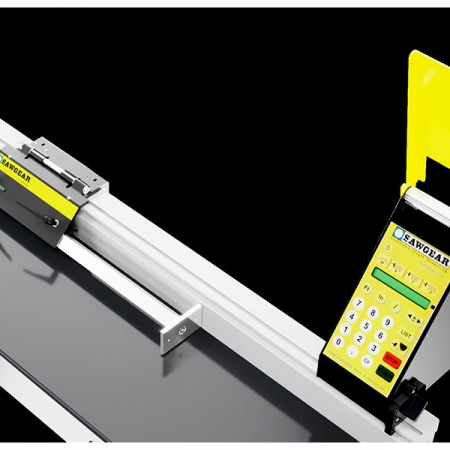

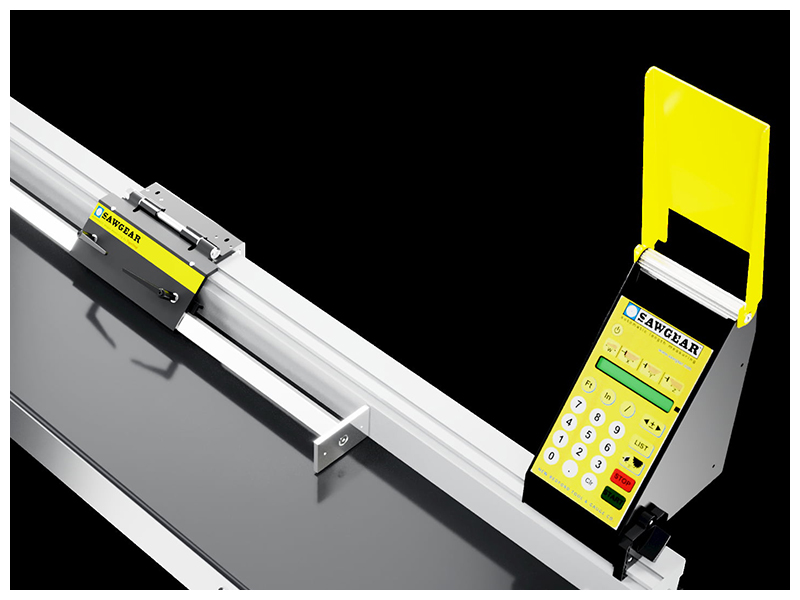

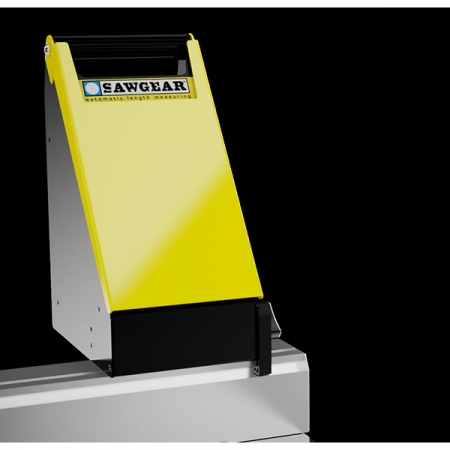

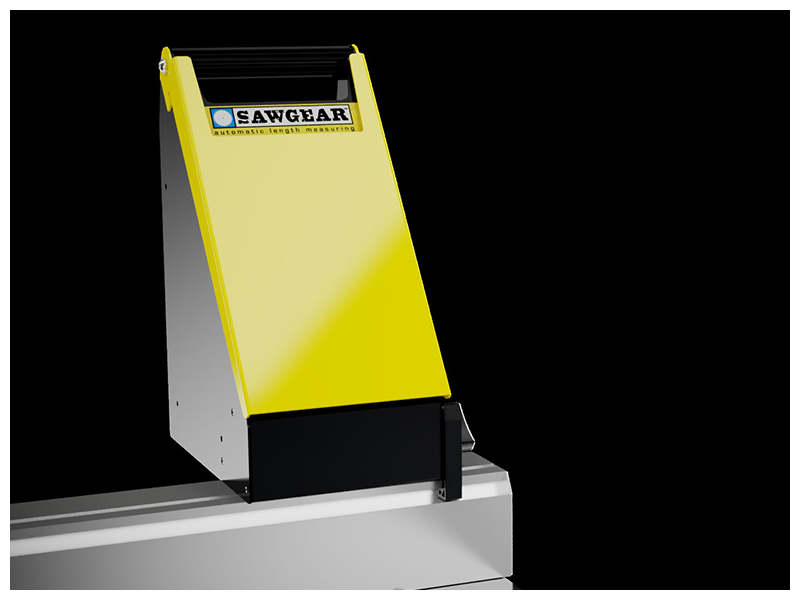

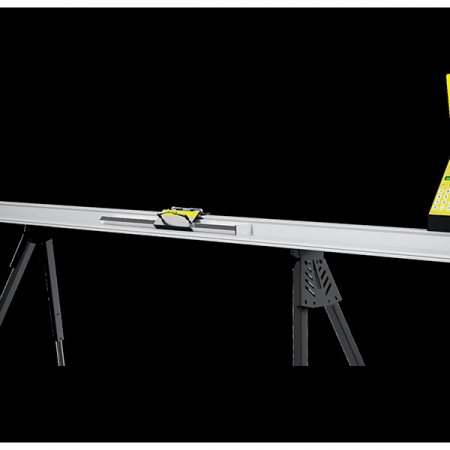

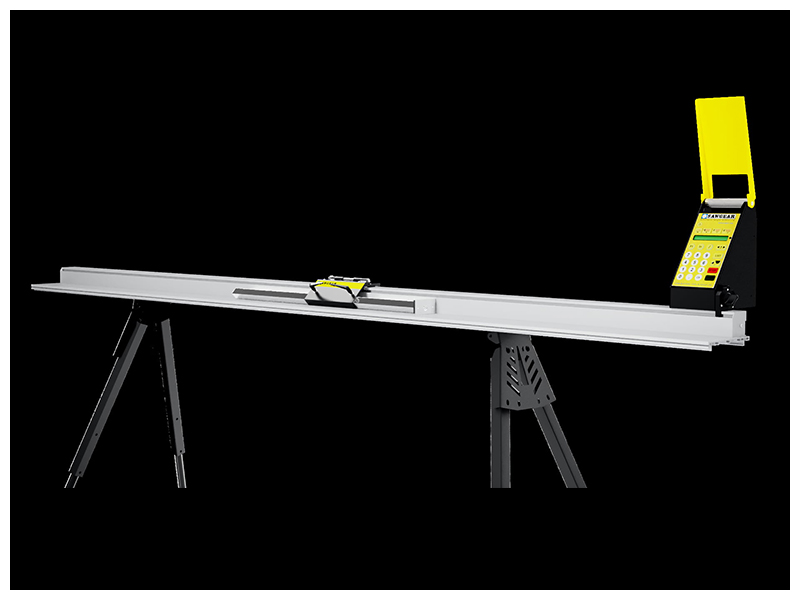

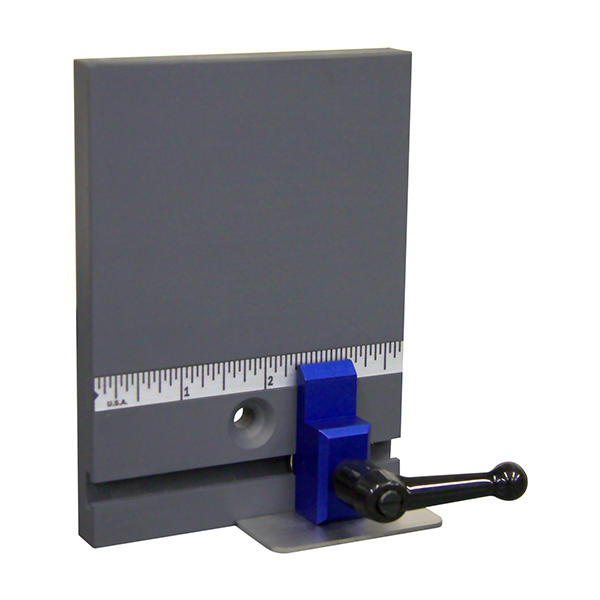

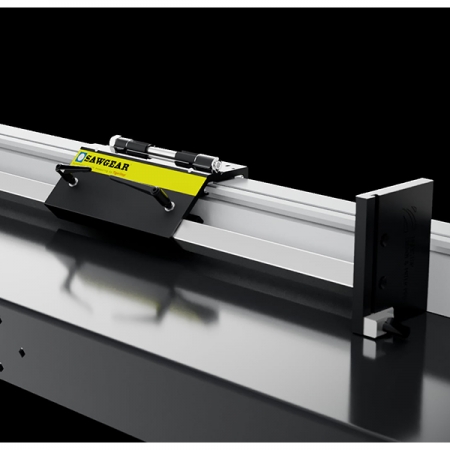

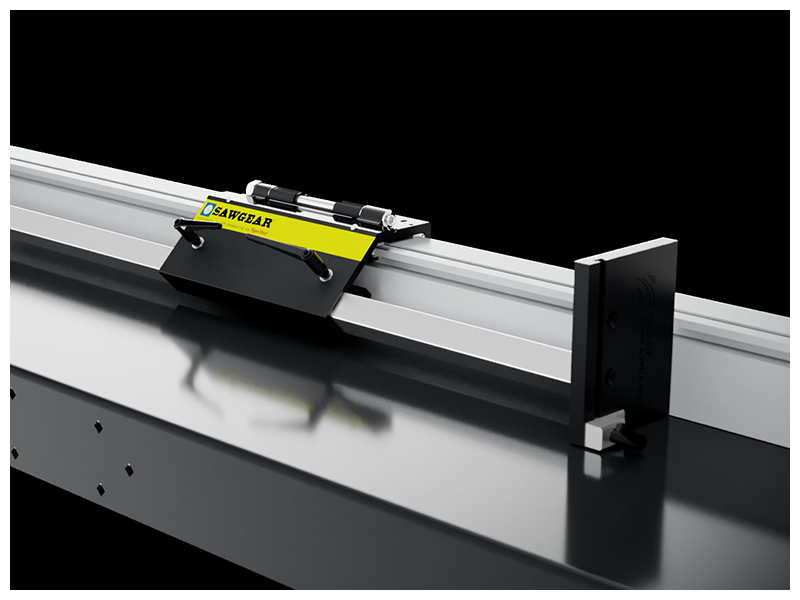

The Tigerstop SawGear Automated Stop is simple and intuitive, and easily attaches to your existing saw, drill, or punch (not designed to push feed). Free yourself from tape measures and manual fences. Produce more parts with increased accuracy today. With a repeatable accuracy of +/- 0.008” (0.2mm), you can eliminate costly rework and increase productivity at the same time. The SawGear is light weight and is portable so it can be taken to the job site. With its simple & fast setup you can be setup and cutting in no time.

Why TigerStop SawGear Automated Stop?

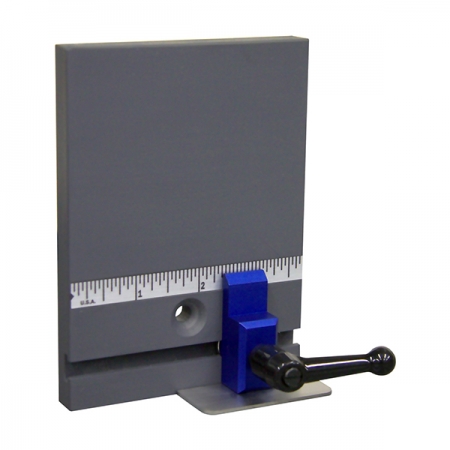

- Zero Set Up Time: Do away with “measure twice, cut once”. Eliminate tape measures, manual stop blocks, and clamps from your manufacturing process.

- 100% Accuracy: The parts you cut today will be as accurate as the parts you cut next week, next month, and next year.

- No More Rework: Quality control starts with SawGear by TigerStop.

- Increased Productivity: Keep your operators in the money-making zone: cycling your saw, drill, or punch.

- Easy to Operate: An unskilled operator can be trained to use a SawGear to position material in under 10 minutes.

- Improved Yields: Raw material costs are rising. Using a SawGear maximizes yields and adds profits to your bottom line.

- Adaptability: SawGear may be used with vertical panel saws and double miter saws, ironworkers, drills, chop saws, and more!

- English, Spanish, French, Dutch, and German

- Crown + Miter Pro Software included

- Convert between fraction and decimals

- Store up to 100 different lengths

- Increments Button

- Metric and Imperial

- Adapts to vertical panel saws, double miter saws, ironworkers, drills, chop saws, and more

- Optional tables and stands

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.