Increase your productivity and put a stop to your costly rework.

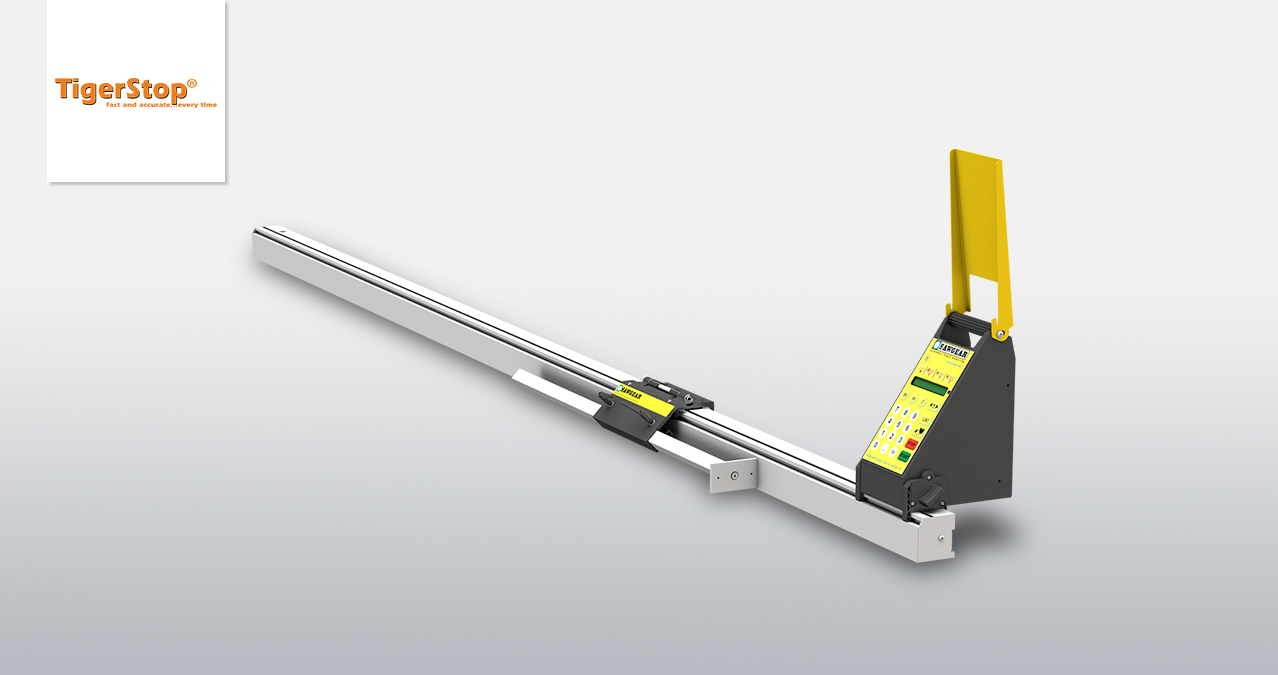

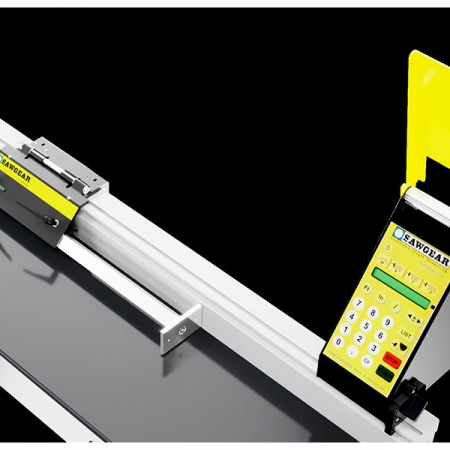

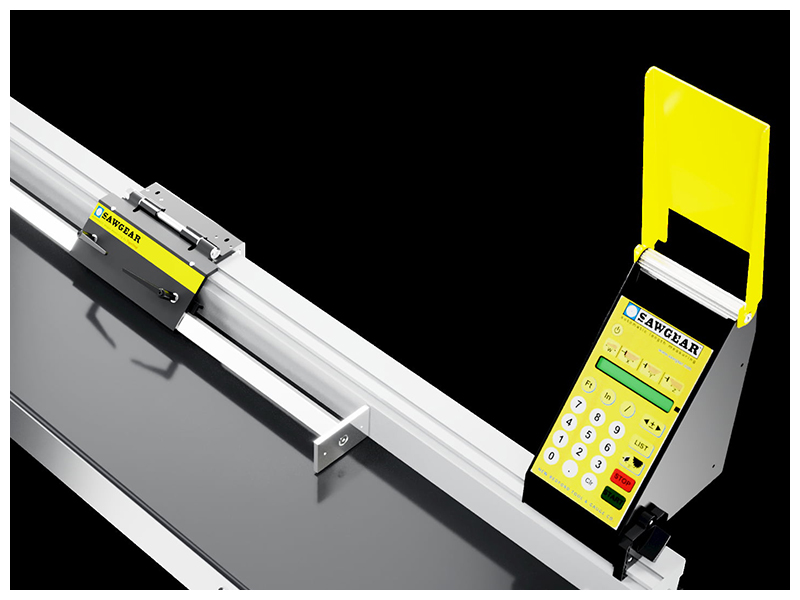

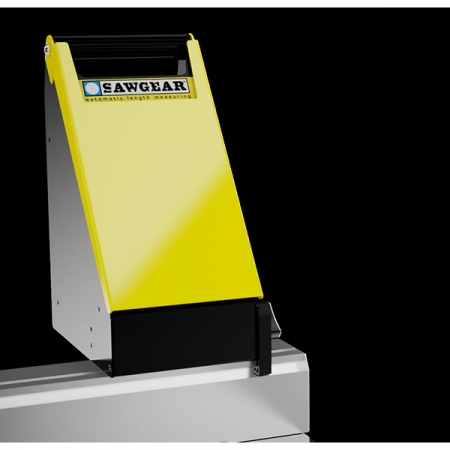

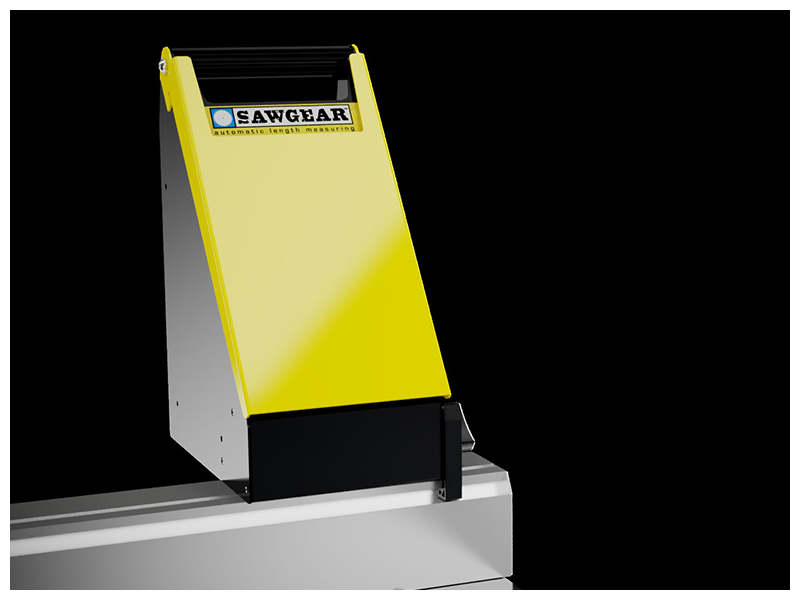

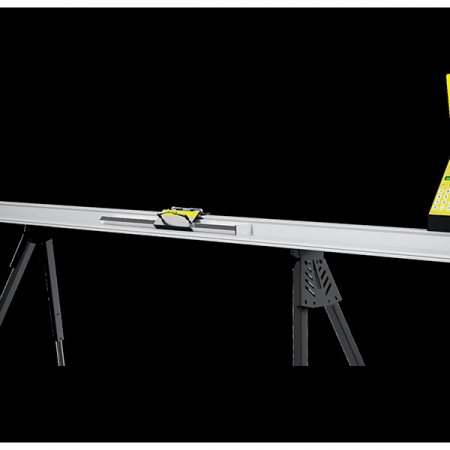

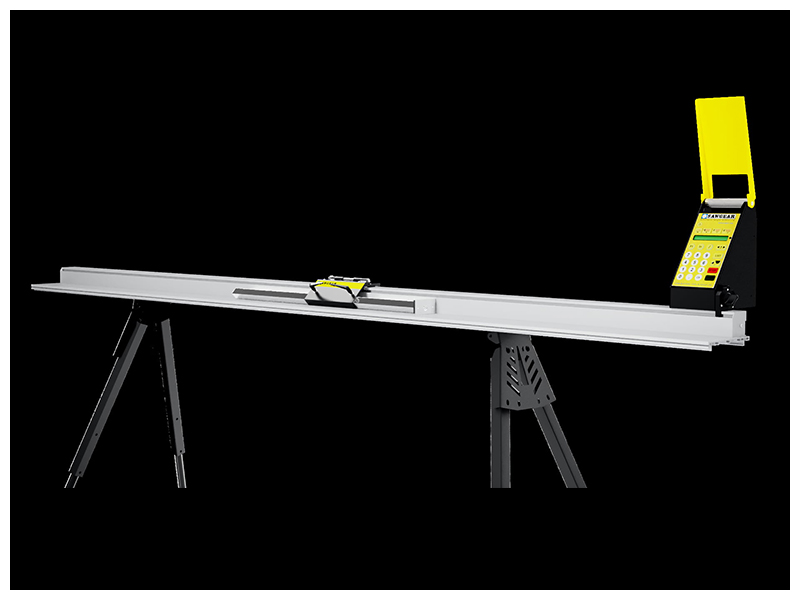

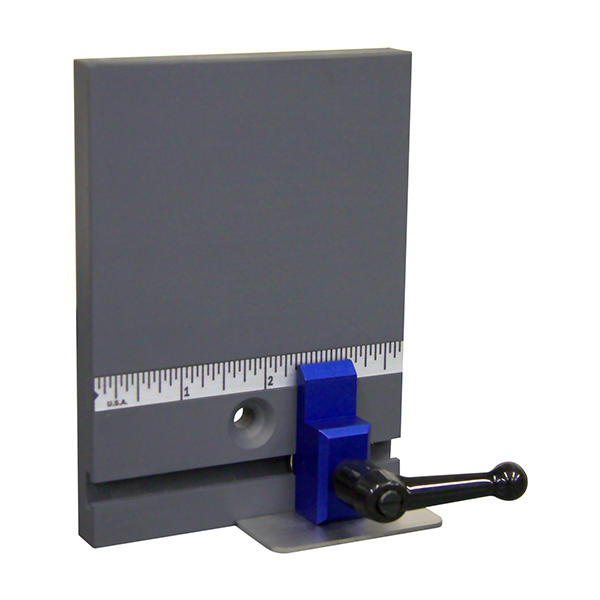

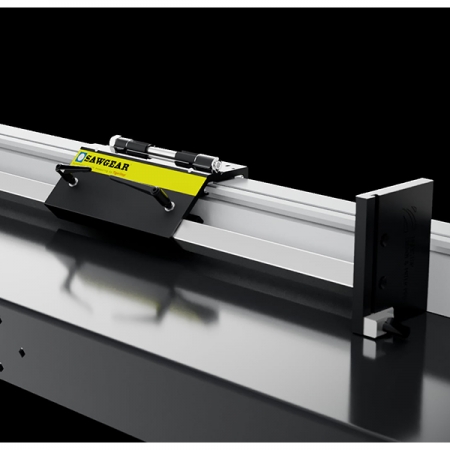

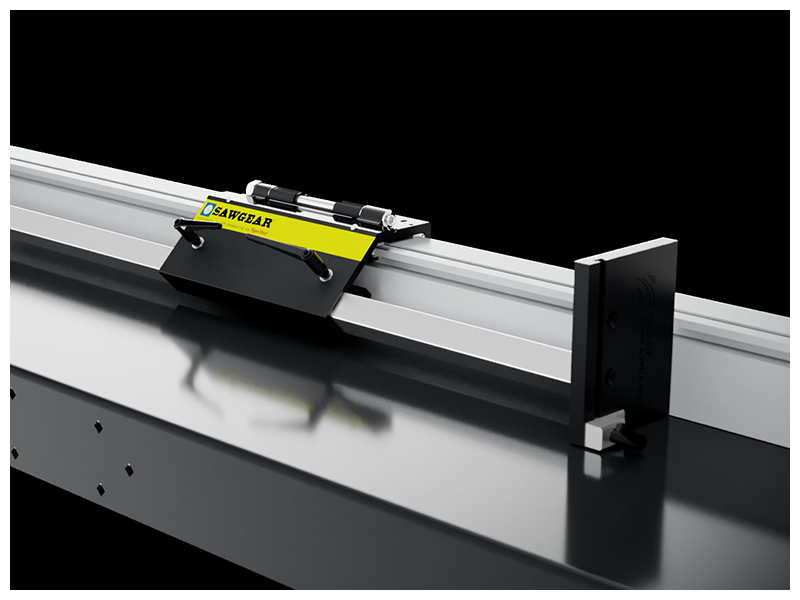

The Tigerstop SawGear Automated Stop is simple and intuitive, and easily attaches to your existing saw, drill, or punch (not designed to push feed). Free yourself from tape measures and manual fences. Produce more parts with increased accuracy today. With a repeatable accuracy of +/- 0.008” (0.2mm), you can eliminate costly rework and increase productivity at the same time. The SawGear is light weight and is portable so it can be taken to the job site. With its simple & fast setup you can be setup and cutting in no time.

Why TigerStop SawGear Automated Stop?

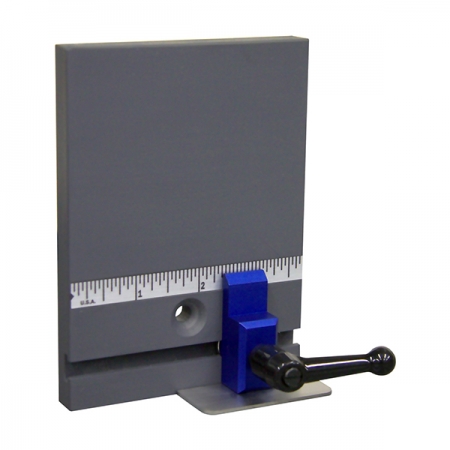

- Zero Set Up Time: Do away with “measure twice, cut once”. Eliminate tape measures, manual stop blocks, and clamps from your manufacturing process.

- 100% Accuracy: The parts you cut today will be as accurate as the parts you cut next week, next month, and next year.

- No More Rework: Quality control starts with SawGear by TigerStop.

- Increased Productivity: Keep your operators in the money-making zone: cycling your saw, drill, or punch.

- Easy to Operate: An unskilled operator can be trained to use a SawGear to position material in under 10 minutes.

- Improved Yields: Raw material costs are rising. Using a SawGear maximizes yields and adds profits to your bottom line.

- Adaptability: SawGear may be used with vertical panel saws and double miter saws, ironworkers, drills, chop saws, and more!

- English, Spanish, French, Dutch, and German

- Crown + Miter Pro Software included

- Convert between fraction and decimals

- Store up to 100 different lengths

- Increments Button

- Metric and Imperial

- Adapts to vertical panel saws, double miter saws, ironworkers, drills, chop saws, and more

- Optional tables and stands

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.