Combining accuracy, simplicity, and affordability to bring you a proven industry leader.

The Summit 20”, 24”, and 28” Precision Engine Lathes have just the right amount of engineering to afford simplicity of operation, coupled with plain and simple rugged reliability. In addition, built in safety features like the safety clutch in the apron that kicks out the feed and the feed/threading safety interlock eliminating the simultaneous engagement of the feed and threading motion, place these machines in a field of their own — unparalleled in performance.

Available in 40″, 60″, 80″, 120″, 160″ and 200″ center distances, the 20-4″, 24-4″ & 28-4″ lathes feature hardened and precision ground bedways on a heavy one-piece closed grain cast bed that is fully ribbed for maximum stability and even thermal expansion. Standard on every machine is a quick-change gearbox for cutting Metric, Module and Diametral Pitch threads as well as standard American threads.

The engineering excellence, fine workmanship, materials and impressive specifications of the Summit 20-4″, 24-4″ & 28-4″ Lathes assure you of greater production and easy, trouble free operation for years to come.

Why Summit 20″, 24″, 28″ Precision Engine Lathes?

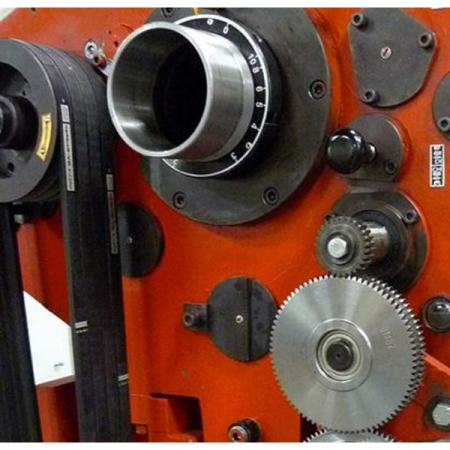

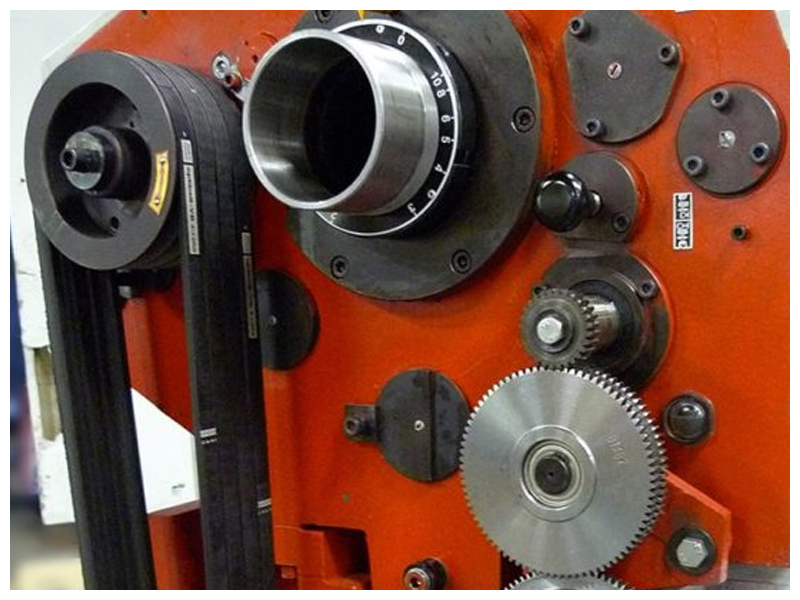

- Cross ribbed headstock for added strength and stability

- Anti-friction mounted shafts and dynamically balanced components

- Hardened and ground allow steel gears, shafts, and splines

- Oversized precision chrome allow spindle with a big 4 1/8” thru hole mounted in double row angular contact thrust bearings and 2 double row roller bearings for greater radial and thrust capacities ensuring very precise turning capabilities

- Hardened and ground bedways

- Big 4 1/8″ thru hole

- Removable gap

- Inch/metric threads

- Conveniently located controls

- Forced lubrication to the headstock, carriage and bedways

- Cuts most American & Metric threads without change gears

- Complete accessory package

- Crossfeed and threading safety interlock

- Feed reversing at the apron

- Hardened and ground cross slide ways

- 4-way rapid traverse

- Heavily ribbed bed

- Single lever control for feeds and rapids

- Full length chip and coolant guard

- 2 speed tailstock

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.