Combining accuracy, simplicity, and affordability to bring you a proven industry leader.

The Summit 20”, 24”, and 28” Precision Engine Lathes have just the right amount of engineering to afford simplicity of operation, coupled with plain and simple rugged reliability. In addition, built in safety features like the safety clutch in the apron that kicks out the feed and the feed/threading safety interlock eliminating the simultaneous engagement of the feed and threading motion, place these machines in a field of their own — unparalleled in performance.

Available in 40″, 60″, 80″, 120″, 160″ and 200″ center distances, the 20-4″, 24-4″ & 28-4″ lathes feature hardened and precision ground bedways on a heavy one-piece closed grain cast bed that is fully ribbed for maximum stability and even thermal expansion. Standard on every machine is a quick-change gearbox for cutting Metric, Module and Diametral Pitch threads as well as standard American threads.

The engineering excellence, fine workmanship, materials and impressive specifications of the Summit 20-4″, 24-4″ & 28-4″ Lathes assure you of greater production and easy, trouble free operation for years to come.

Why Summit 20″, 24″, 28″ Precision Engine Lathes?

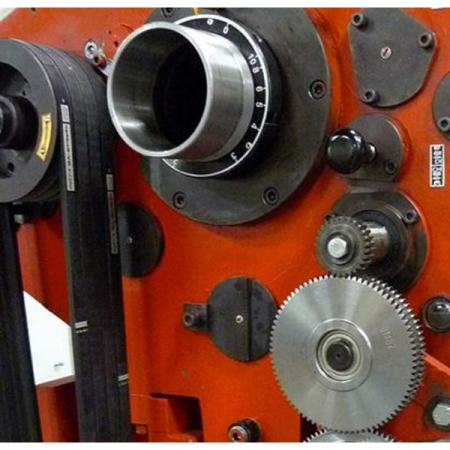

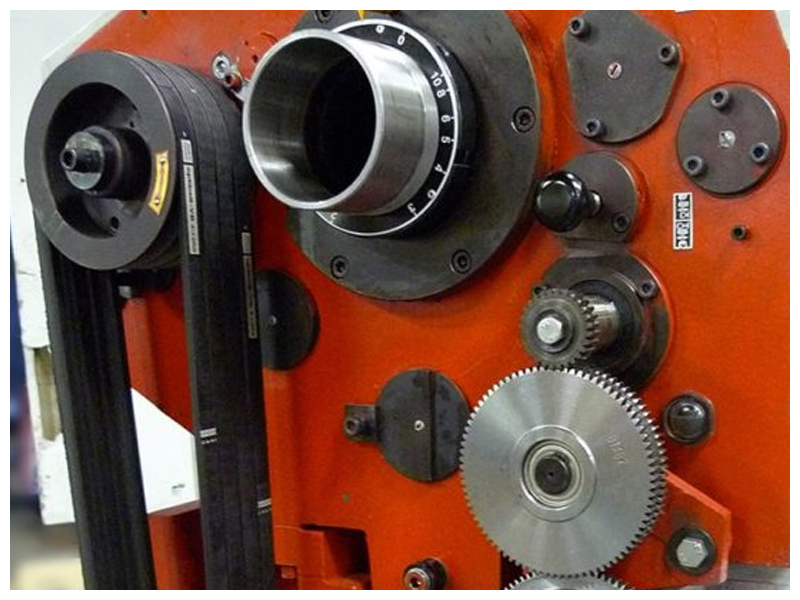

- Cross ribbed headstock for added strength and stability

- Anti-friction mounted shafts and dynamically balanced components

- Hardened and ground allow steel gears, shafts, and splines

- Oversized precision chrome allow spindle with a big 4 1/8” thru hole mounted in double row angular contact thrust bearings and 2 double row roller bearings for greater radial and thrust capacities ensuring very precise turning capabilities

- Hardened and ground bedways

- Big 4 1/8″ thru hole

- Removable gap

- Inch/metric threads

- Conveniently located controls

- Forced lubrication to the headstock, carriage and bedways

- Cuts most American & Metric threads without change gears

- Complete accessory package

- Crossfeed and threading safety interlock

- Feed reversing at the apron

- Hardened and ground cross slide ways

- 4-way rapid traverse

- Heavily ribbed bed

- Single lever control for feeds and rapids

- Full length chip and coolant guard

- 2 speed tailstock

One Anderson.

Corporate, Machinery SolutionsAkhurst has made the move to distribute all of Anderson’s machines under one brand, Anderson. Anderson is the world leading CNC router manufacturer, with over 20 thousand machines sold worldwide and 5 thousand only in the US market.

Visit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.

Corporate, Machinery Solutions, Trade ShowsThe WTD is back with extended dates, now giving visitors five days to visit our members’ extensive showrooms and see the latest new technology, including some North American premieres. No other show or single event offers you such a wide display of woodworking equipment, combined with impressive live demonstrations at each location.

High-end cabinetry, movie stars, Marvel has it all.

Case Study, Corporate, Machinery Solutions, Service and SupportMarvel Cabinetry, from De Winton, AB, is the exclusive cabinetry supplier for the first and second seasons of Property Brothers’ Celebrity IOU on HGTV, and has designed and built made-in-Canada cabinetry for stars across North America. Among them were Michael Bublé, Brad Pitt, Snoop Dogg, Gwyneth Paltrow, Melissa McCarthy, Viola Davis, Jeremy Renner, Kevin Hart, Howie Mandel, and LeAnn Rimes, and Marvel invites you to be next.