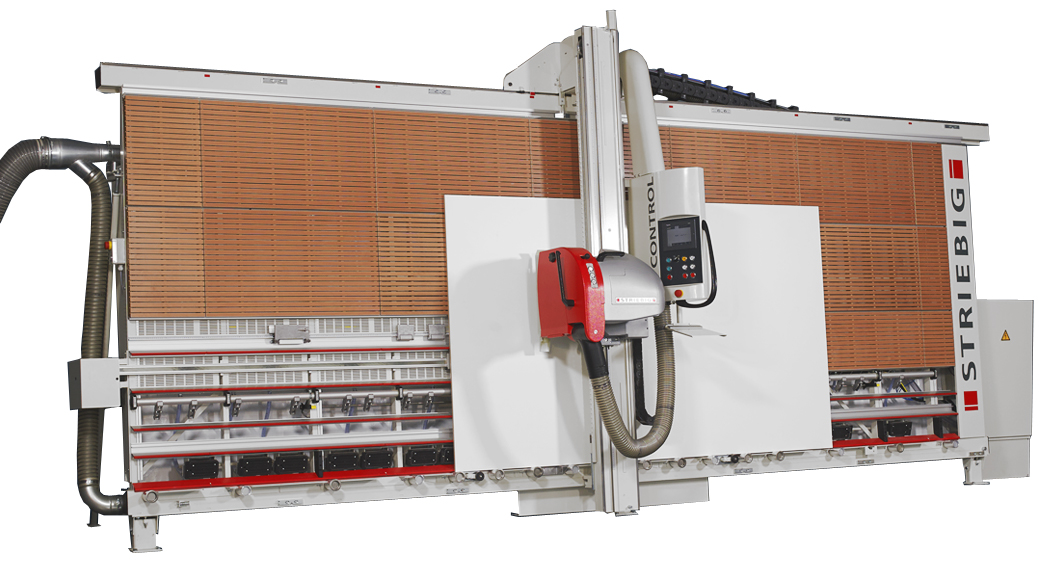

Machine Information

Features

Push button control – and everything runs automatically

- Cuts 5′ 6″ x 14′ 1″ (larger frames available)

- Very stable, all welded steel frame suitable for free-standing or wall-mount installation

- Convenient, sturdy, mid-shelf allows for comfortable working of small parts

- Automatic locking of the heavy-duty panel support rollers when cutting cycle is started

- Automatic, mechanical, upward-shifting support grid with full support for thin or small material

- Digital measuring is standard with fine adjustment, easy reference setting, push-button changeover from rollers to mid-shelf to strip cutting, and selectable display increments

- Second measuring channel with three auxiliary stops for repeat cuts

- TRK dust collection system exceeds European standards; note: requires external collector

- Vertical cutting stations 40 inches on center (1 meter optional)

- Automatic locking of beam at cutting stations; push-button unlocking

- Control panel displays operating hours and faults (language is selectable)

- Equipped with 7-1/2 hp, 220/440 volt, 3-phase motor with electric brake

- 300 mm (11-7/8″) HFG carbide saw blade

- Template bar with six stops for setting typical horizontal cuts

- Automatic saw travel with variable feed rate 10-30 m/min. (33-98 ft./min.)

- Selectable sawing cycle (cut and return, or cut and stop)

- Panel end sensor to save time (instead of having to travel to end of saw)