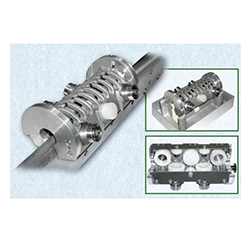

When the grinding requirements are extreme, the Reform Type 5 is your only choice.

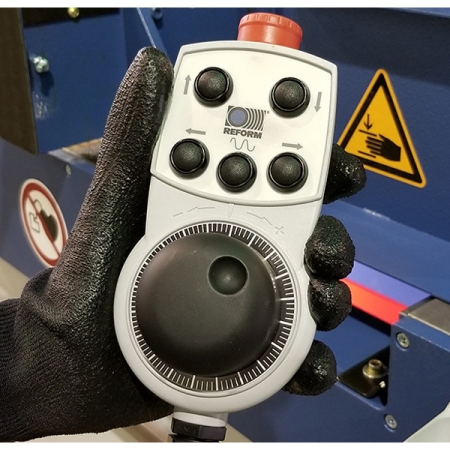

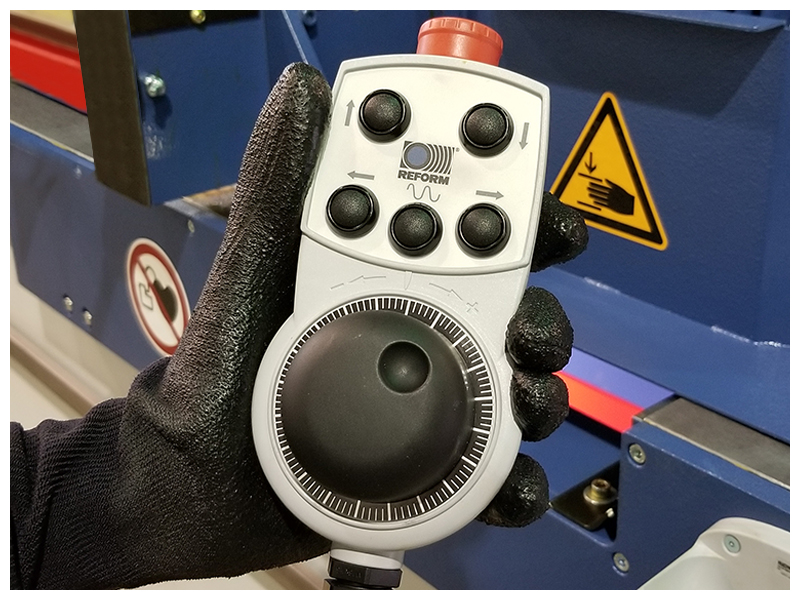

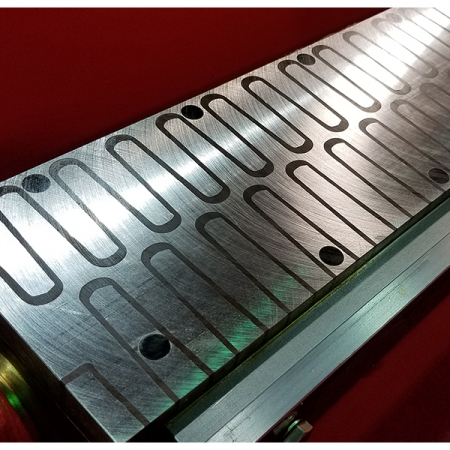

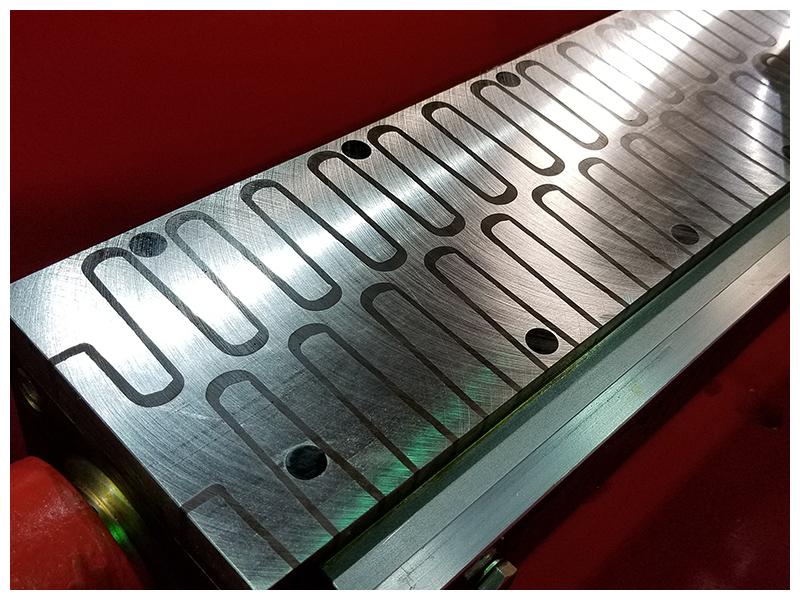

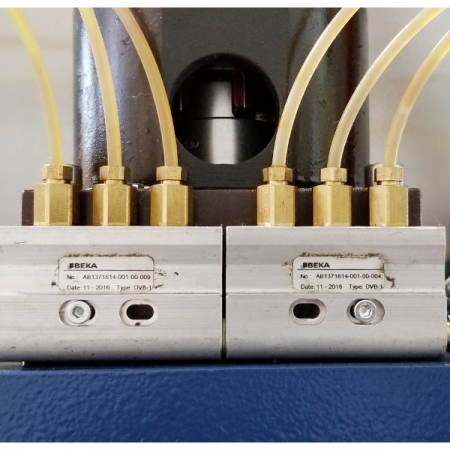

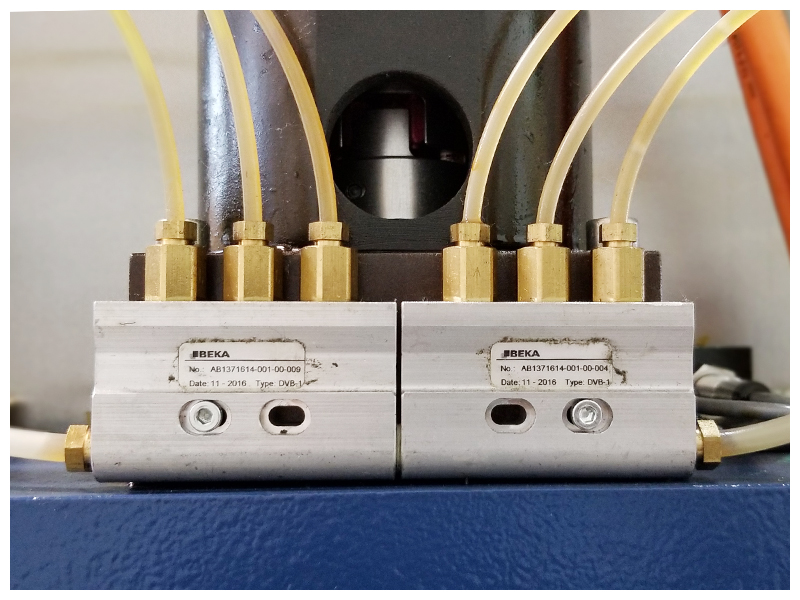

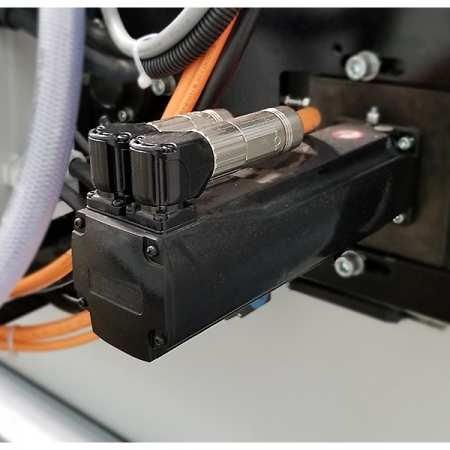

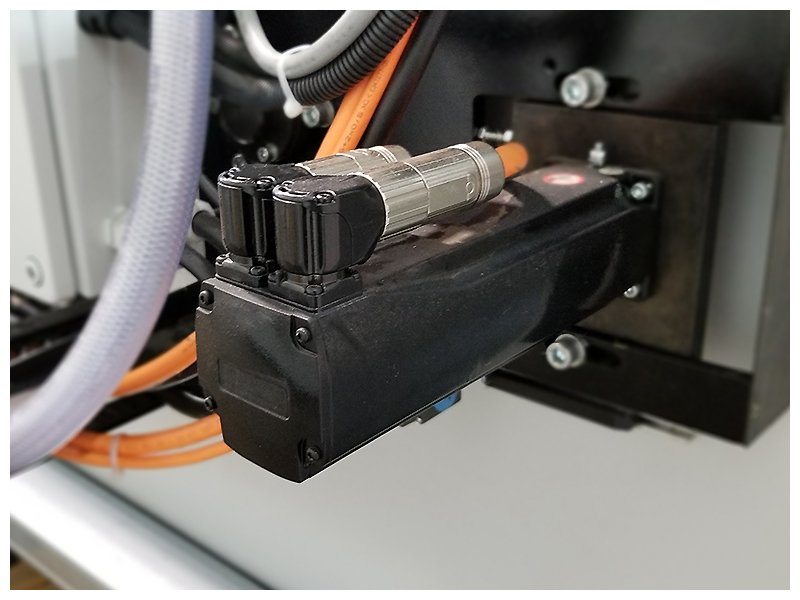

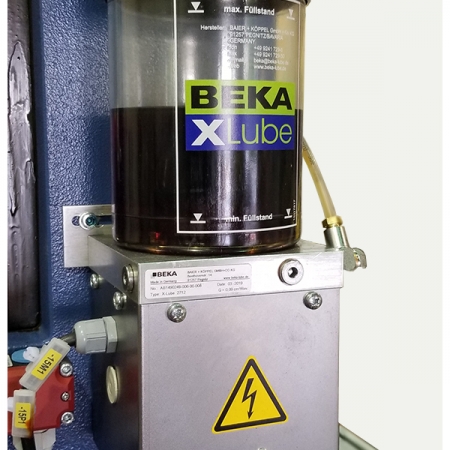

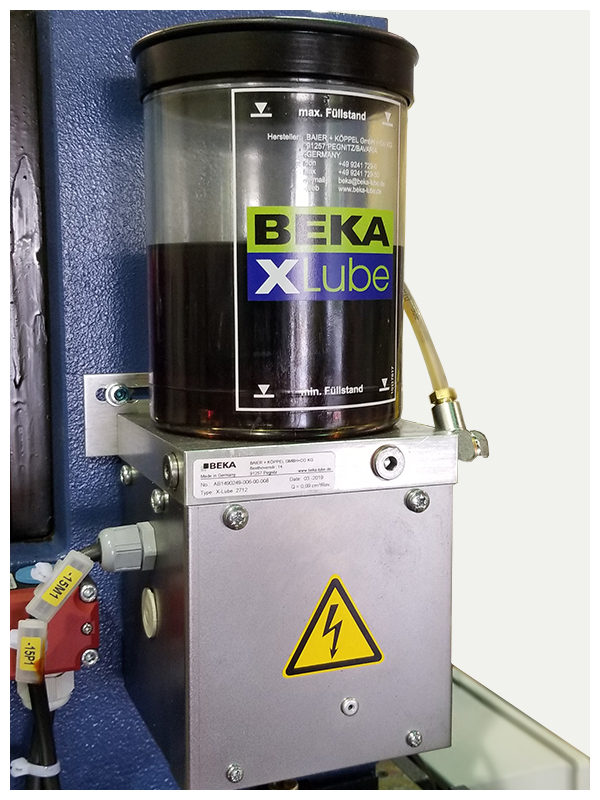

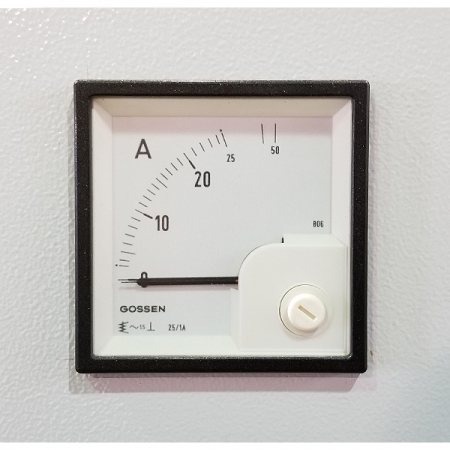

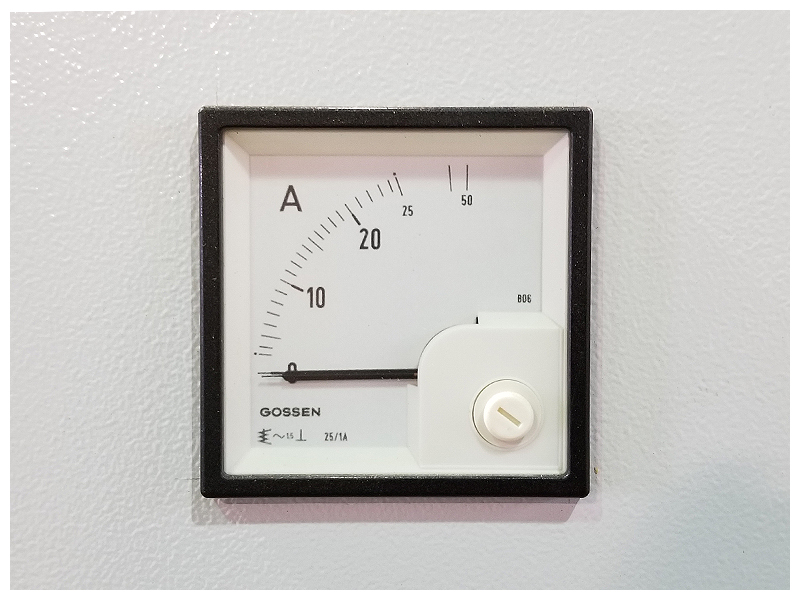

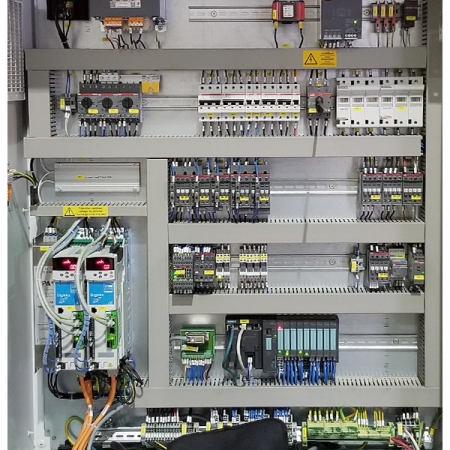

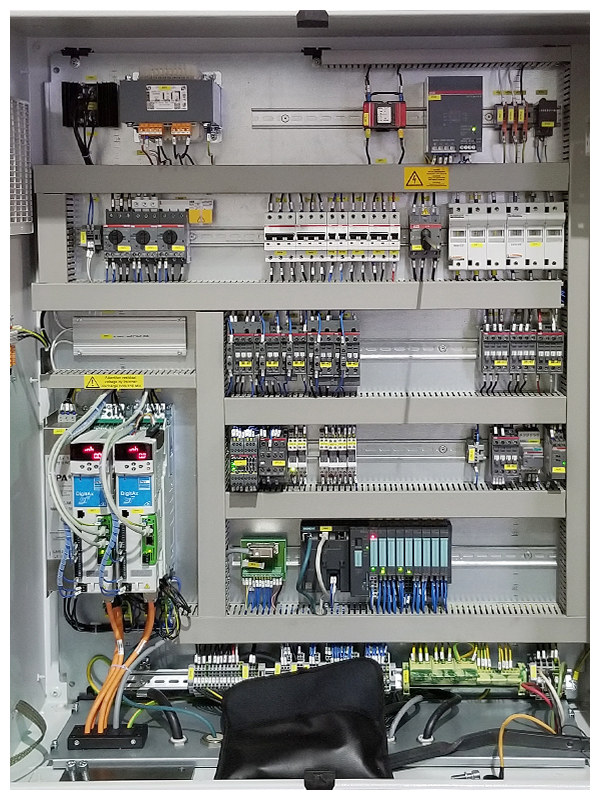

The modern Reform Type 5 Knife Grinder series is a perfect example of cutting-edge knife grinding capabilities. Known industry-wide for its durability and retained accuracy over decades of continuous use, no other grinder offers this level of continued performance. The cellular construction of the stress relieved base provides unmatched stiffness and vibration dampening. With Reform’s convenient LCD electronic controls, each stage of the grinding process is safely and conveniently operated, observed, and adjusted. This includes the touch-off, rough grinding, finish grinding, and spark-out stages. The design of the Reform Type 5 allows for the grinding industry’s safest operation of knife grinding equipment. All changeover work is done from the front of the unit. This includes the quick-change capabilities of knives, grinding stones, wheels, and abrasives. By leveraging classic Reform dependability now matched with the best available technology, programmability, repeatability, and results, less demand on the operators translates to quicker grinding cycles.

Why Reform Type 5 Knife Grinder?

- The German engineering and manufacturing process of the Reform Type 5 series of grinders is the best available. Each machine is still fully designed and constructed in Germany.

- The proven history of the Reform line of grinding equipment’s reliability and performance can be trusted without concern.

- Industry’s best options for occupational health and safety including work area accordion-style covering, UL4 mist exhausters, and grinding coolant cleaners.

- Industry’s best design for performance, safety, and efficiency.

- Simple programmability for repeatable results.

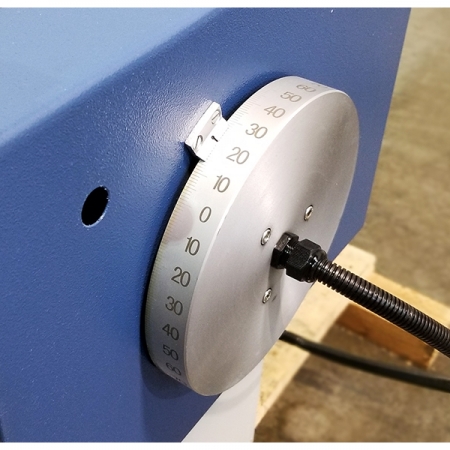

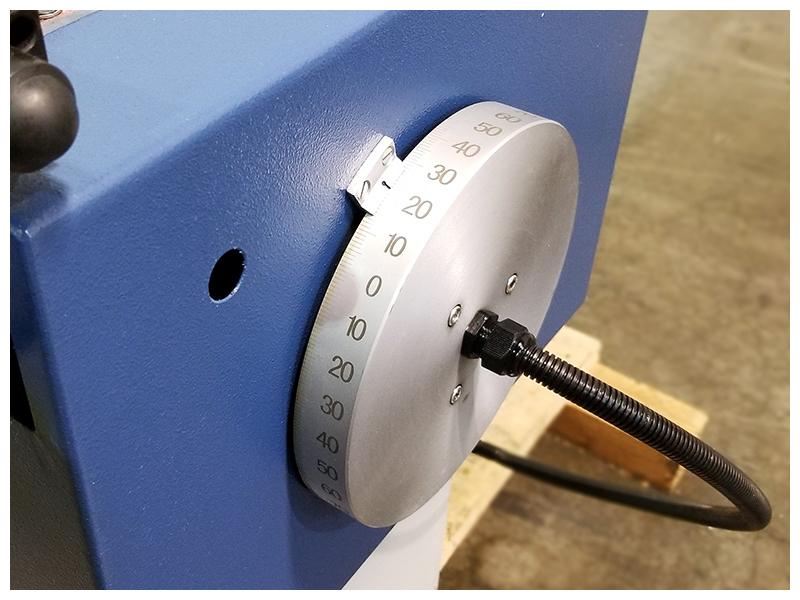

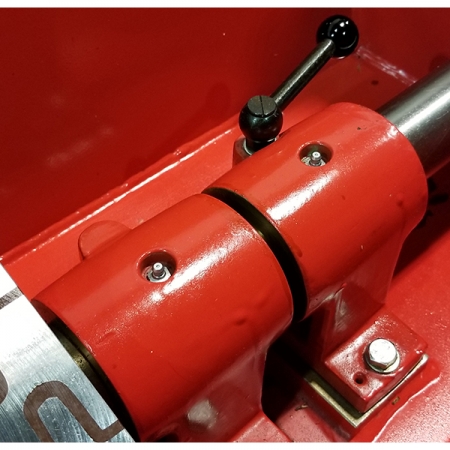

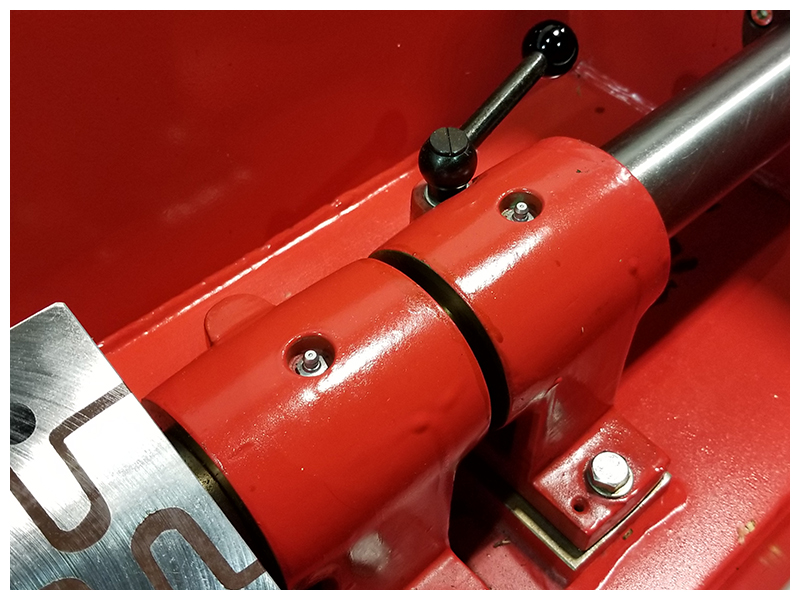

- Swivelling magnetic chuck.

- Edge alignment hardware.

- Reversible grinding carriage.

- Electronic quick-adjust stroke length limit switches.

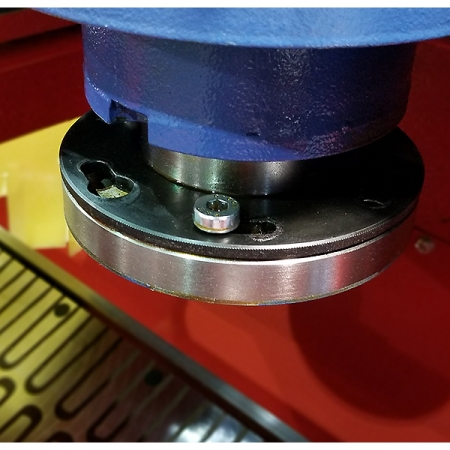

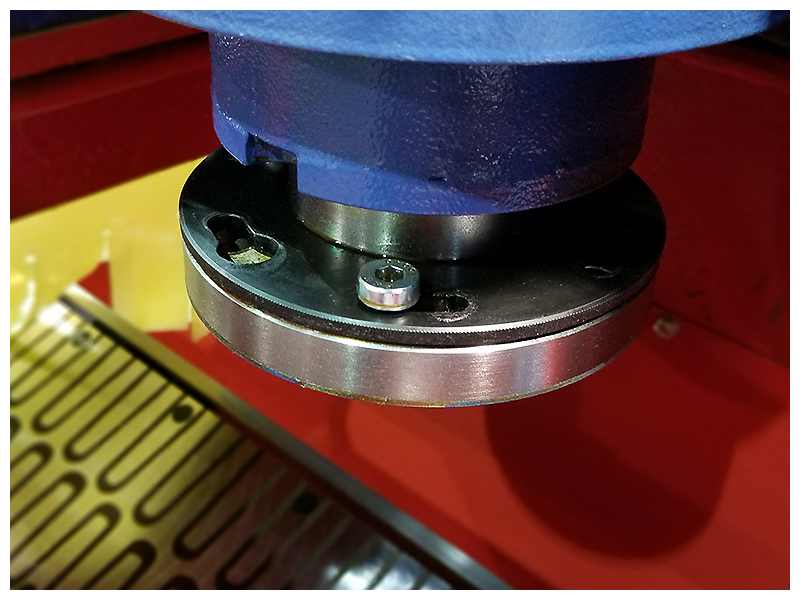

- Quick change 10” grinding wheel backing plate.

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.