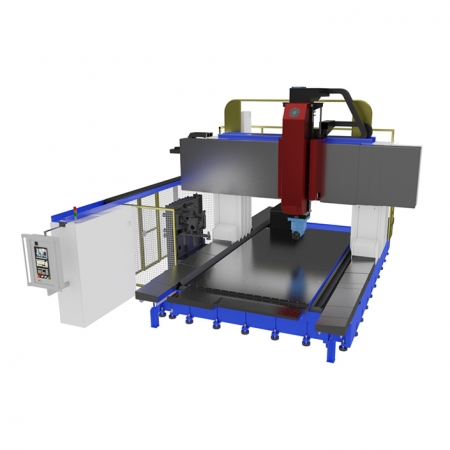

The Job Shop Powerhouse.

The Quickmill Annihilator Gantry Machining Center was designed with one thought in mind: to deliver over-the-top performance to not just set you apart from your competitors. To ANNIHILATE them.

With the speed and precision of a fighter jet and the power and strength of a freight train, the Annihilator can handle anything you throw at it. The rigid gantry design combined with our high-speed axis drive system allows for faster processing times, allowing you to process your parts with ease. The Annihilator is not for those who are content with ‘good enough’, it’s for those who understand the true value of the performance; for those who want the job done right.

This is not your run of the mill machining center, this is the metal chewing, tough as nails Annihilator Gantry.

Why Quickmill Annihilator Gantry Machining Center?

- X/Y/Z Travels from 60”/180”/26” to 120”/220”/26” for Standard Models

- Wide variety of table sizes, Z_axis gaps, and spindles to choose from

- Well suited for the machining of any big, heavy, awkward parts

- Capable of taking on applications like milling and drilling forged flanges, machining of automotive part molds, machining of draw dies, machining of offroad wear edge parts, drilling heat exchanger tube sheets, general purpose machining, and more

Full line CNC router and storage system double production and decrease lead times.

Case Study, Corporate, Machinery Solutions, Service and SupportCuisi-n-art, of Gatineau, Quebec, with an eye to the future, undertook a large construction project to double the size of their manufacturing facility and increase their production capacity. The centrepiece of their manufacturing plant expansion was implementing two Anderson Stratos Pro Full-Line CNC Routers and Schelling material storage system.

CNC Series: Vacuum, when design and efficiency mean everything.

Machinery SolutionsWhen it comes to vacuum, hold down a bigger pump is not necessarily the answer. More important is the design of the vacuum table and how efficient it is at holding small parts during machining operations.

CNC Series: Weight, where bigger is better.

Machinery SolutionsProducing with optimum cut quality, increased production, and superior cutter performance. Choosing the right solution for your shop involves research and understanding which match your production expectations and future goals.