Your Everyday Ironworker.

The Peddinghaus PeddiWorker 100 Ton Ironworker meets the needs of fabrication shop detail work, both large and small. It comes with a 900 KN cylinder and a 4 kW motor. With the 100 ton hydraulic press, the PeddiWorker is easily able to punch and shear heavier steel.

Why Peddinghaus PeddiWorker 100 Ton Ironworker?

- Minimal footprint to easily fit into your shop and your budget

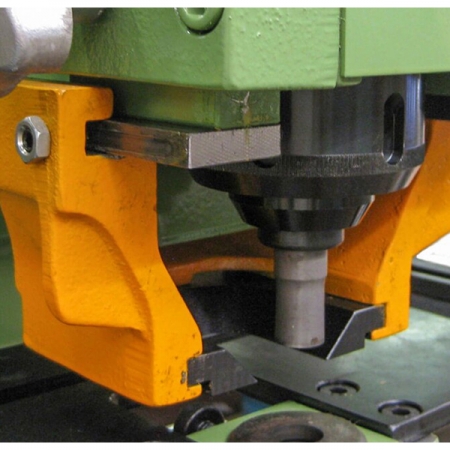

- Precision slide design and integrated cylinders that provide a true 90° approach to every workpiece in all punching, shearing, and notching operations.

- Generated force is equally distributed throughout the slide and body plate frame design, not through the hydraulic cylinder, which eliminates shock and stress of the ironworker hydraulic system

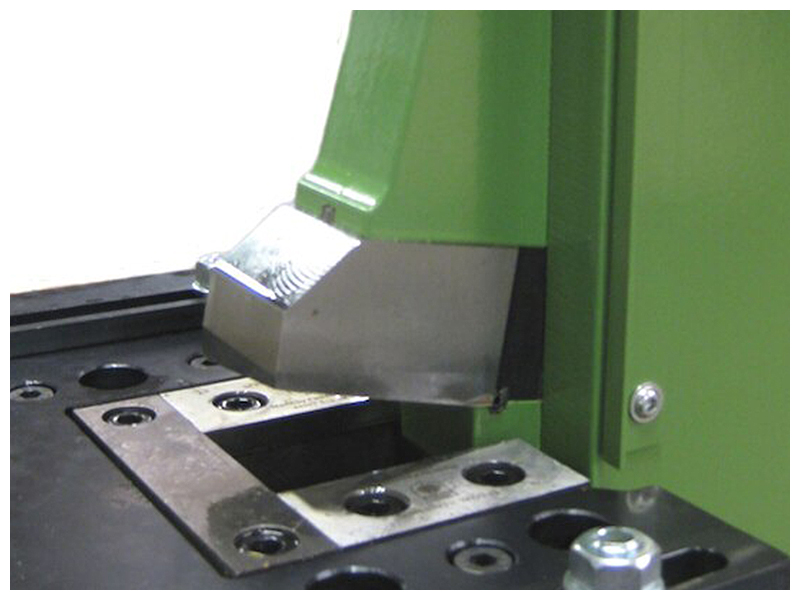

- The swing away stripper and quick-change couple and locking unit make changing tooling a fast and easy process to save time between jobs

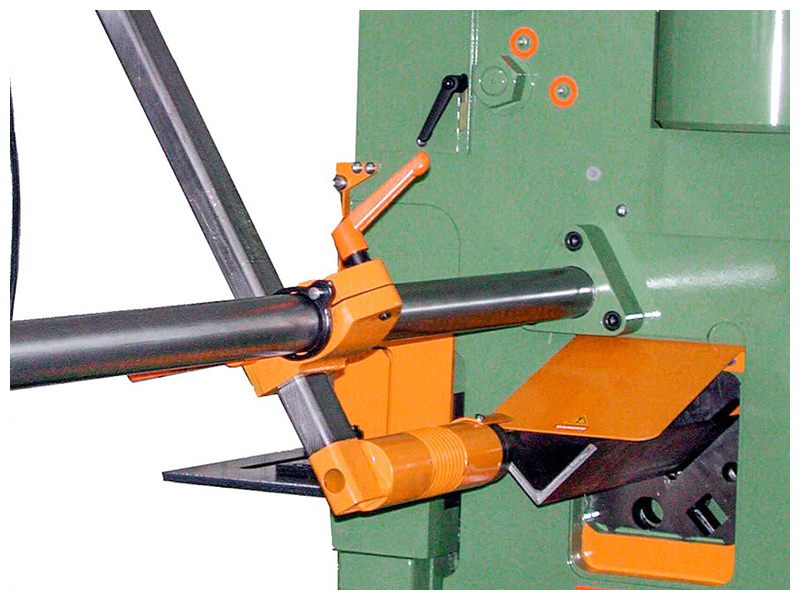

- With heat-treated blades combined with the guillotine shearing action, the flat stock shear provides minimal distortion cuts and will shear up to 400 mm x 20 mm material

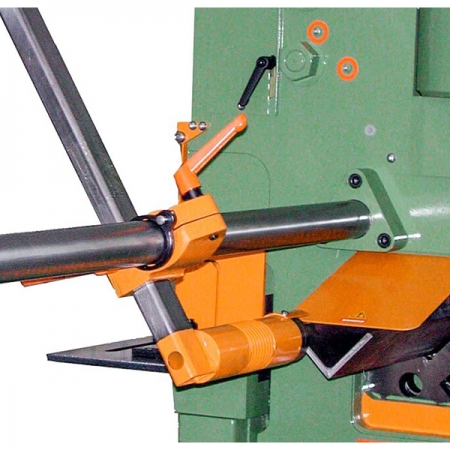

- Standard section shear blades allow for the shearing of angle stock up to 150 mm x 150 mm x 12 mm and bar stock up to 40 mm for both round and square material

- Get smooth notches in flat stock, channel, and angle because of the vertical movement of Peddinghaus’ notcher

Quality in the Details

With the 100 ton hydraulic press, the PeddiWorker is easily able to punch and shear heavier steel. Perfect for miscellaneous projects with angle, flat, square or round bar stock.

Robust Build for Longevity

As for all Peddinghaus machines, this ironworker follows suit by withstanding the test of time. Where it all started, is not an uncommon sight to see a Peddinghaus steelworker from the early 1900s still in operation within a fabrication shop. No ironworker boasts the track record of durability as Peddinghaus does.

Length Stop

Perfect for mass production, the length stop feature on the PeddiWorker diminishes guesswork for a constant operator feed.

Notching and Bending

Additional notching and bending tools add even more versatility to this hydraulic ironworker machine. The notching end includes a worktable with guide rails for more convenient work.

Akhurst Machinery Group announces strategic partnership to aid North American housing crisis.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the North American machinery industry, is pleased to announce a strategic partnership with Modular Building Automation (MBA), a Dutch company specializing in machinery for prefabricated homes, modular buildings, and offsite construction solutions. MBA, a joint venture of the renowned companies J.J. Smith in the UK and Ireland and H&M headquartered in the Netherlands, is involved in the design, manufacturing, distribution, and worldwide sales of MBA equipment.

Akhurst Machinery Group announces strategic partnership with Stromab.

Corporate, Machinery SolutionsAkhurst Machinery Group, a prominent player in the machinery industry, proudly announces a strategic partnership with Stromab SPA, an Italian manufacturer of innovative crosscutting solutions. This collaboration signifies a major commitment by both companies to bring cutting-edge technology and comprehensive solutions to the North American market. Akhurst Machinery Group, the parent company behind the well-known brands of Cantek and Leadermac USA, will leverage Stromab SPA’s expertise in crosscutting solutions to enhance its offerings in North America.

Woodworking Technology Days 2023 is just around the corner.

Corporate, Machinery Solutions, Trade ShowsVisit us during this year’s Woodworking Technology Days and see the latest equipment solutions for your business.